All about plumbing and sewage

Pumping stations and treatment facilities

Sewer

Plumbing

Firefighters

The Admiral Plant produces complete pumping stations for the needs of water supply, fire fighting and sewage.

Admiral Plant Website: admiral-omsk.ru

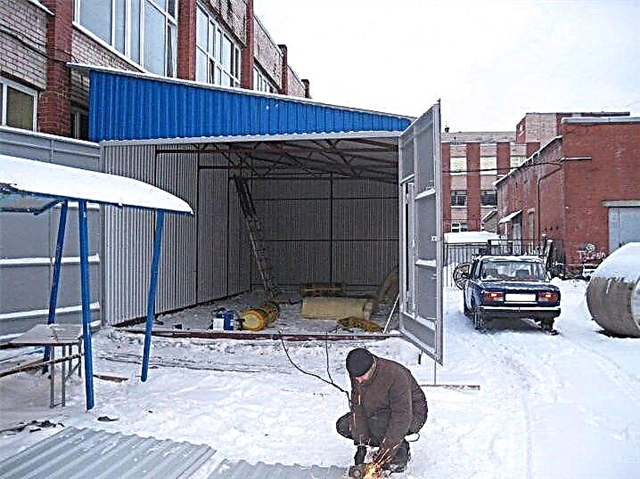

Metal garage: advantages and disadvantages

For the safety of cars should be put in storage in the garage. There are a large number of varieties of garages: brick, wooden, steel and many others. Recently, metal garages are increasingly being built, as they are cheap and easy to install. When choosing this type of design should take into account their advantages and disadvantages.

Advantages of metal garages

To begin with, we pay attention to the fact that metal garages can be built using a wide variety of materials. The main operational qualities depend on the type of material used. The general positive qualities of such a structure include the following points:

- If the structure is not separable, it can be freely transported from one place to another. Of course, such rigging works cause difficulties, but disassembling a brick garage and erecting it elsewhere will be much more expensive.

- Democratic cost is the reason why many erect steel garages. As the main building materials, steel or a metal profile can be used.

- Durability and durability. It is worth considering that metal is one of the most durable materials of its kind. It yields exclusively to brick and concrete. When protecting the surface by applying a special coating, you can ensure the service life of the structure for 10 years or more.

- Simplicity of installation work allows you to save on the construction of a garage. Today, many decide to do their own work because the cost of construction services is constantly growing.

It is worth considering that metal garages can be used as a private workshop or for storing various things. Locks of various types can be built into garage doors.

Main disadvantages

There are also significant drawbacks to metal structures. There are several of them:

- Fire vulnerability. If something burns near the building, then the fire can go to a steel garage, especially if insulating flammable materials were used to finish it.

- Initially, there is no protection against low temperatures and noise penetration. It is worth considering that temperature jumps cause the formation of condensate. In this case, condensate may fall on the car, which will adversely affect the paintwork. Corrosion is the main enemy of metal; some parts can begin to wear out quickly because of this. Therefore, it is recommended to protect the structure from exposure to high humidity.

- Problems in the winter are icing castles. Because of this, their opening is difficult, the wear of the main elements increases. In addition, such garages make it difficult to carry out repair work in the winter due to the low temperature. As for cars with diesel engines, it is difficult to start them in the cold, the wear of the structure due to oil starvation is significantly increased.

- If the design of the garage is not fixed on the site, then the attackers can gain access. To do this, it will be enough to adjust the lifts and raise the structure. The light weight of the structure determines the possibility of using a jack.

- A little security against breaking is also characterized by the fact that a padlock is used to lock the gate. It is practically impossible to install a mortise due to the fact that the gate does not have the proper width.

- Design features do not allow communication. The lack of electricity leads to the fact that to carry out repairs in such a garage will not be possible.

We consider in detail the features of garages, which are made of certain materials.

Features

Not always a person has extra money and time to build a warm capital garage. In addition, garage communities in most cities are located outside the city limits. If you take into account the daily use of the car, then there is a need for extra spending on the road to your garage cooperative. Reducing the cost of building a garage and paying labor, owners often consider options for building a separate metal garage.

Recently, the leaders of many municipalities have begun to struggle with the construction of iron garages in urban areas. Despite this, such designs are still popular among motorists. This phenomenon is explained by several aspects:

- The most challenging factor is construction costs. The cost of building a major brick or block garage is disproportionately high. Assembling a metal structure is much cheaper.

- Fulfillment of the order for the manufacture of elements of the future metal garage and their delivery to the place of assembly will take only a few days.

- Assembly usually does not take much time and effort and does not require special skills.

- If necessary, a metal garage can be made collapsible.

As in any business, when building a metal garage, the car owner must take into account the existing shortcomings, among which:

- Iron garage practically does not retain heat. In the event of sudden temperature changes, condensation may occur. This phenomenon has a bad effect not only on the car, but also on the structure itself.

- Typically, buildings of this type are not equipped with electricity. This minus makes car repair and maintenance very difficult. High probability of freezing locks. In a cold room, it’s more difficult to start and warm up the car.

- Easy assembly can allow attackers to easily get close to the car.

It is not recommended to place metal structures near flammable objects. In case of fire, there is a possibility of flame penetration into the garage.

Despite the flaws listed above, the metal garage is convenient and reliable in operation. As for the flaws, they are easily eliminated by proper arrangement.

Types of construction

Despite the fact that a metal garage is not unusual, many car owners are lost in the variety of designs on offer. Their main distinguishing feature is the method and place of manufacture and the service life prior to acquisition. When buying a garage, you need to pay attention to the warranty, licensing and title documents of the seller.

It is possible to build a collapsible iron garage with the participation of a pair of assistants, having only the basic set of tools (hammer, wrenches, pliers) available. In factory kits of excellent quality, all fasteners and components usually do not cause difficulties in assembly. Moreover, you do not need sophisticated equipment to fit the elements. Many of the enterprises engaged in the manufacture of metal structures can deliver their goods to the place of assembly.

In some cases, the owner himself has to spend money on the removal of the structure from the plant. One way or another, the only significant drawback here is the inflated cost due to transportation.

Sometimes an enterprise, in addition to standard sets, may offer production according to individual customer requests, taking into account the area of the site for construction or the size of the car.

On informational portals for sale or exchange, you can find a used factory or homemade version. The advantage in this case is the price, which is significantly lower than the cost of new samples. However, note that a self-built monolithic garage due to its size may not be suitable for transportation. For delivery, special equipment will be required, there is also a risk of deformation. In addition, during many years of operation, parts of the garage may shrink, making it difficult to disassemble.

Self construction

The most inexpensive, but time-consuming option is the construction of an iron garage in the home, from the base to the roof. With the construction of a building with your own hands, you can significantly save on materials. If you calculate all the construction options, then building materials can be prepared in advance, and then begin construction.

When constructing a garage with your own hands, the car owner decides what the future home for his car will be like. In the event that long-term operation is planned, it is necessary to make a calculation in advance, taking into account all sizes and parameters, and draw up a drawing. By purchasing additional materials, you can weld a warm and comfortable “house” from your metal for your car. Depending on the place of construction and further operation of the garage, it will be superfluous to consider both monolithic and portable construction options.

During the construction of a non-demountable garage, one should determine its functionality. It will be up to the owner to decide whether this building is just a box for parking a car or a building with tool cabinets and a workbench. The metal structure should be installed on a flat platform, so that pouring the foundation will not be superfluous. It is not required to deeply deepen it, since the structure does not give large loads.

An important nuance is the installation and fixing of embedded parts. It can be reinforcing pins or threaded anchors. By pins by welding or thread, the lower girdle of the garage is attached.

It is necessary to precisely align the anchors not only in the corners, but also on the walls of the future garage.

Sometimes a garage is located on a flat plot of land. In this case, runners from pipes with a diameter of more than 10 cm are used. Inside the structure of the floors, it is necessary to fill up with a layer of gravel or make wooden flooring. In the absence of sex during bad weather, bare earth, for example, in the form of black soil, can cause certain inconvenience to the driver. In addition, constant dampness inside will be provided.

To solve the problem of lack of space in a metal garage, you can add an attic floor. Indeed, in addition to storing the car, storage of technical fluids, tools and things unnecessary in the apartment should be provided in the garage. In this case, the presence of an additional storage room on top will help free up extra centimeters. Yes, and the two-story garage looks more colorful.

FAQ

One way or another, but the time comes when the garage needs repairs. Usually flaws appear on the roof. If a leak in the ceiling is detected, it is necessary to start eliminating it as soon as possible, since the safety of all objects in the garage, including the car, entirely depends on this.

An inexpensive option is the application of water-based acrylic paint, which is sometimes called "rubber". After drying, such a material forms an elastic layer that prevents hostile environmental influences.

If additional damage is discovered, the following must be done:

- Small cracks and holes can be repaired with tow, soaking it in front of this hot resin.

- Holes of large diameters are sealed with pieces of roofing material or burlap. Previously, the surface is cleaned and coated with bitumen.

- A sheet of roofing iron is superimposed on very large holes, on top of which a patch is applied. This eliminates the sagging patched area.

For roof overhaul, roll materials are mainly used. These types of coatings have high strength and elasticity. The roof of the garage, repaired in this way, has excellent heat resistance and moisture resistance.

Garage walls and gates sometimes also require repairs. Most often this is due to the destructive effect of moisture. For non-through defects, it will be enough to clean and prime the damaged area, then paint it. Through a rusted area, it is better to replace or weld a metal patch, having treated it with an anti-corrosion compound.

Garage walls and gates sometimes also require repairs. Most often this is due to the destructive effect of moisture. For non-through defects, it will be enough to clean and prime the damaged area, then paint it. Through a rusted area, it is better to replace or weld a metal patch, having treated it with an anti-corrosion compound.

In order to prevent serious violations, it is necessary to fill the space between the inner lining and the wall with liquid insulating material at the finishing stage. This will not only increase the heat resistance, but also improve the protection of the metal from corrosion. It is also necessary to monitor the good air circulation inside the garage. With normal air exchange, condensation is virtually eliminated.

No matter how strong the floor or foundation, traces of cracks may appear on it. In this situation, it is required to make a screed around the entire perimeter of the garage or the area of the concrete floor.

The construction of the garage can already be considered completed after the installation of gates, locks and entry equipment. But a caring motorist will always consider it necessary to protect his car from frost or the hot sun. For this, sheet polystyrene foam is suitable, because it is cheaper and more convenient during installation.

The optimal solution to the problem may be the use of mineral wool. Mats or rolls of insulation are fixed on the walls, gates and ceiling. After this stage is completed, the insulation elements are covered with sheets of plywood or wood board. Further, after facing inside the garage, you can begin to design work.

In the garage, shelves and small cabinets are usually hung. If lighting is provided, fixtures are fixed. In conclusion, the garage can be painted outside with weather-resistant paint and outdoor lighting can be installed.

Building your own metal garage allows you to not only equip a parking lot for your car, but also acquire locksmith and construction skills. The main thing in this matter is no need to be afraid to try something new and always take into account all your mistakes.

Useful Tips

Perhaps, given these recommendations, the future owner of the garage will be able to get around some unpleasant nuances:

- When making a deal, you need to require a check, as there are known cases of fraudsters selling other people's orphan garages.

- The slope of the floors should always be towards the exit, and it is undesirable to use only bare soil as the floor.

- Expanded polystyrene, of course, is cheaper and more convenient to install, but can often react with the fluids used in the car. This material is also highly flammable.

- Electrical wiring is usually done prior to wall decoration to prevent accidental breakage and shorting.

Which garage is better: iron or brick?

A motorist before buying a garage should still weigh all the nuances. Residents of rural areas are most likely to use a brick or reinforced concrete option. The construction of a stone garage is already considered a capital and reliable structure and can be legalized as a building.With the proper decoration of the room inside and outside, optimal conditions for storing the car are achieved. In such a garage, you can equip a viewing hole, a basement, legally conduct lighting and heat.

Among the shortcomings, one can single out only the high cost of acquisition or construction and a smaller area for placing a car with the same allocated territory for construction.

A metal garage is suitable for owners who do not have their own plots. Metal structures are more mobile for transportation, require little time for disassembly and installation.

Such a garage can be insulated with inexpensive materials that do not require finishing. However, the metal requires periodic painting to avoid corrosion, and the design of such a structure will require more time.

It can be seen that the advantages and disadvantages are in both cases. Deficiencies in iron garages are easily eliminated, which makes them more popular. If budget size and conditions allow, then it is better to opt for a brick building. In any case, the garage should become a reliable and comfortable home for the car.

You will learn about how to independently make the basis for a metal garage from the next video.

How to assemble a design

It is not difficult to assemble a metal garage case. For installation, metal equal-angle corners of 35x5 millimeters are used. A more durable and expensive option is to use a profiled pipe.

The order of operations is as follows:

Why is the manufacture of metal garages so in demand today

A metal garage is a metal construction that protects a car from external influences and unauthorized access.

Such garages can be assembled using various types of metal structures.

- Iron sheets. They are used as the skin of the frame, giving the structure the necessary rigidity. Thick sheets of steel that withstand heavy loads are best suited for cladding. However, there are garages sheathed with a thick professional sheet. Such structures are not reliable enough, although they do not lose in their bearing capacity to steel structures.

- Metallic profile. For the manufacture of metal profiles usually use metal corners, round and shaped pipes. A structure assembled from such a profile has monolithicity and the ability to withstand high loads.

The finished product is installed either on a pre-constructed foundation, or on a leveled land. In terms of strength, metal garages are practically not inferior to brick buildings.

Many car owners prefer metal garage buildings because of their objective advantages:

- Resistance to fire. The metal will never ignite or support the combustion process. In the event of a fire nearby, a metal garage is relatively safe.

- High strength. A car garage of high-quality and durable metal is difficult to crack, although the resistance to breaking of monolithic structures from classical building materials is slightly higher.

- Relatively low cost. The cost of such a garage in its manufacture will depend only on the installation method and the quality of the metal parts. Most often, the price is lower than the cost of a classic brick or aerated concrete structure.

- The metal structure is not legally considered a monolithic structure. For the construction of a metal structure does not require appropriate permits.

- Speed and ease of installation. Even a beginner in construction can assemble such a structure. The modern market offers for the manufacture of several types of prefabricated metal structures for cars. It is important to mount them correctly, guided by the attached instructions.

- Relatively light weight. Due to its low weight, the metal structure is mobile and can be moved if necessary. With monolithic car garages, such an operation is impossible.

However, such designs have disadvantages:

- The minimum level of thermal insulation. The metal has high thermal conductivity, as a result of which the metal garage does not hold heat well, and it becomes rather uncomfortable to work inside both in severe frost and in hot weather. Therefore, it is recommended to warm the structure during its manufacture with various materials. Also, rapid heating and cooling of the metal walls of the garage leads to the formation of condensate, which negatively affects both structural elements and the car itself.

- Inability to install electricity. Safety precautions prohibit the electrification of such buildings. Electricity can only be supplied if autonomous generators are used.

- Low fire safety. Although the metal does not support combustion, it can heat up quickly. The slots available in the construction also contribute to the penetration of open fire from outside to inside, which poses a certain danger to property inside.

- The minimum level of protection. This moment concerns the car garages installed in the manufacture on the ground or other base without fastening to it. With a great desire, the whole structure can be lifted with an ordinary jack. Metal is also easily cut with cutting or special wheels. Brick garage in this regard is much safer.

Types of structures for the manufacture of metal garages

Before the construction of any metal structures, it is required to calculate in advance all the necessary technical parameters. For this, certain skills are needed, however, it is possible to calculate simple garages without experience.

According to the design features, metal garages are divided into several types:

Factory buildings.Basically, these are mobile collapsible constructions, for the manufacture of which only simple tools are needed (a hammer, a set of wrenches, etc.) and assembly instructions with drawings. The resulting products are practical and durable, but they are more expensive compared to solid structures. In terms of size, such a garage is usually not larger than an average one-story building.

Used buildings of this type are found on various trading portals. Their prices are lower than the cost of similar new products, and delivery conditions often involve pickup from a specified location.

Garages built by hand. A feature of these buildings is a wide variety of their configurations and unique technical characteristics. Sometimes you can find two-story buildings used by the owners as additional warehouses.

Some types of metal structures in the manufacture of rigidly attached to the foundation by welding. As a result, the design gains increased strength and durability. Self-installation of the garage will require certain skills, competent calculation of parameters and special tools, so assembly should be done exclusively by specialists.

Where to start manufacturing a metal garage

The construction of any building must be carefully planned in advance to avoid unforeseen situations and to ensure maximum durability and strength of the future structure. Preliminary steps in the manufacture of a metal garage are as follows:

- Choosing a place for construction. It is advisable to arrange the construction in a place convenient for access and arrival, and by the road, if the place is on an individual land plot. Metal garages are always set on a hill away from a residential building. In the lowland, the garage will be constantly flooded with groundwater or meltwater, as a result of which it will rapidly begin to rust and become worthless.

- Foundation preparation. The site must first be cleaned, achieving a flat and horizontal surface. Probably, this will require removing the topsoil.

- Design. There are no universal instructions here. First of all, the garage should be such that the used car is easily placed inside. If the design will serve not only to store the car, but also to store spare parts and carry out repair work, the dimensions of the garage before production should be increased accordingly.

It is widely believed that a blueprint is not needed to make such a simple building as a garage. This opinion is erroneous, because in the process of its operation a lot of unaccounted details may appear that will lead to unpleasant situations. A detailed drawing is an integral part of the project, and not just an assembly diagram.

According to the completed project, you can accurately determine the required amount of consumables and their total cost. Self-creation of a scheme allows you to assemble the design in your mind, taking into account all the nuances. In addition, this makes it possible to determine the tools for the work.

The finished metal garage project should take into account:

- the presence of insulation and ventilation.

When creating a project, you need to clearly understand the purpose of the garage. For work on maintenance and repair of the car, as well as for the storage of spare parts and materials, additional space is required. Shelves, tables, a workbench and other auxiliary furniture will be placed on it. You should also pay attention to the type of lighting and the location of the fixtures.

Assembly and manufacturing of metal garages

The process of assembling a metal garage is simple. However, it is better to carry it out with assistants who will hold the supporting elements during their construction and in time to submit the required parts of the structure.

Recommended Reading

Before assembling the garage, a foundation is built for it. It is not recommended to install the structure directly on the ground, otherwise it will give an impetus to the development of corrosion.

To mark the trenches under the foundation, it is necessary to determine the dimensions of the garage. The width of the trench is approximately equal to the width of the shovel bayonet, and the depth is within 150-300 mm.

After the trench is dug, a layer of ASG is laid on its bottom and then carefully rammed. To avoid getting into the structure of flood or rain water, it is advisable to make the top of the foundation 100–200 mm above the ground level. This will require the manufacture of formwork.

During the pouring of the concrete base, reinforcement pins are installed at the corner points of the foundation and in the middle of the sides of its perimeter, to which the garage will be fastened with its lower edge. Concrete dries in about 48 hours, after which the construction of the car garage itself can be erected.

The following types of foundations are used for structures of this type:

- Monolithic. This type of base is able to withstand high loads. However, for the manufacture of lightweight metal structures, its use is not justified. It makes sense to use only the already existing monolithic foundation.

- Floating. This is a reliable and relatively cheap type of foundation. When it is erected on pre-compacted soil, reinforced concrete slabs are laid around the perimeter of the garage. Laying of plates is carried out by a truck crane and requires certain financial investments.

- Tape. For the manufacture of metal garages, this is the most optimal type of foundation, it is quite simple to erect. During the construction of the garage, a trench with a depth of not more than 50–80 cm is dug around the perimeter - this thickness is enough for small metal structures. Then a mixture of sand and gravel is poured at the bottom of the trench, which is subsequently rammed.

To increase the strength of the foundation, you can lay a layer of granite stone and pour it with a solution of cement. Formwork is built on top and poured with concrete mortar. The height of the formwork should be selected individually depending on the state of the soil and personal needs. It is not recommended to build too high a base, as this will require a greater consumption of materials for leveling the floor.

Metal fabrication as a whole consists of the following steps:

Frame construction. After manufacturing, the frame has the shape of a parallelepiped with additional posts that strengthen the walls. On the side where the gate is planned, an internal frame structure is being constructed. The frame elements are interconnected by welding, which provides the entire structure with the necessary rigidity. If you use bolted connections to fasten the elements, the frame will become loose over time, its rigidity will be violated.

The roof of a metal garage can be single or double. In the latter case, it should be possible to connect the roof structure with the garage frame. In the manufacture of a gable roof, its structure, consisting of triangular elements, is attached to the main load-bearing supports. Roof logs are connected with each other by metal jumpers.

- Sheathing. This relatively simple step begins at any angle in the structure. The metal sheet is welded or screwed to the frame elements. In the second case, profiled sheets are used, which can be chosen for structures of any size. It is extremely important to prevent the formation of gaps between the sheathing sheets, providing the most dense joints, boiling them qualitatively or covering with additional sheets of metal in case of fastening by welding. When using professional sheets, they should be overlapped.

- Gate installation. An additional, pre-prepared frame for the gate should be adapted to the dimensions of the opening. Then the hinges on which the gates are hung are welded to the main posts of this frame. It must be ensured that the gate leaves do not form gaps and completely cover the opening, preventing air from entering the structure.

- Warming. This is an optional step, which, however, is almost always carried out. Mineral wool is often used as insulation, the mats of which are placed from the inside between the profile pipes in the manufacture of a metal structure. To protect the insulation from moisture, it is closed with a plastic film. After laying, the insulation mats are closed with sheet metal or other finishing material.

The quality of the structure, its strength and durability can be ensured by following the basic rules:

- For the manufacture of the garage should use exclusively high-quality metal. Avoid products with traces of corrosion, otherwise in the future this will lead to unscheduled repair of the structure.

- To protect metal parts in the manufacture of a garage, cover them with appropriate primed paints and varnishes. Otherwise, the surface will quickly rust.

- If a heater is used, do not lay electrical wiring inside it.

- Service and car repairs will be simplified by a survey hole in the garage. It should be foreseen at the design stage of the entire structure.

- Equip the gate with several locks for more reliable protection against breaking.

The metal garage is practical and versatile. Subject to the construction technology, it will become a full-fledged place for storage and maintenance of the vehicle.

Tips for choosing gates for metal garages

Currently, several types of garage doors are used.

- Lifting sectional. They are a construction of several metal plates fastened together by special loops. The sash of such panels, when opened, is lifted using a lifting mechanism, which is attached to the ceiling and walls at the doorway. Smooth movement is ensured by bearings and rubberized rollers available in the panel joints. Thanks to these elements, the gates smoothly rise and fall along the rails.

- Rolled (rolling). They are called so because of the opening technology and consist of the following elements:

- sash elements (lamellas), interconnected,

- guide profiles along which the web moves,

- lever to unlock the mechanism when the power is cut off,

- the shaft on which the roll is wound.

- Lifting and swiveling. They look like a one-piece panel covering an opening. The design of the metal frame allows you to place it in the open state under the ceiling, at an angle of 90 ° to the closed position. The main supporting element is the frame frame, so it is made of steel. The gate wing itself is also steel. Opening and closing is done remotely by the electric drive, so you can control the gate directly from the car.

- Double wing swing. Due to its reliability, simplicity and cheapness, this type of garage door is most popular in the manufacture of metal structures. They consist of two wings, hinged to the support posts. To ensure rigidity, the racks are made in the form of a solid metal frame. The design allows you to open the sash both outward and inward, depending on the needs of the owner. Often in one of the wings make a door for people.

Each type of gate has features that satisfy the specific needs of the car owner. If necessary, in the manufacture of a metal garage, the gates are equipped with sliding or lifting mechanisms provided for a particular type.

In all the variety of types and designs, it is sometimes difficult to make the right choice. In order not to be mistaken, when choosing, you need to take into account some of the points below.

First of all, check the quality of the polymer coating of the gate. In the case of galvanized metal, a galvanizing method that directly determines the durability of the product is important. For garage doors, parts galvanized by powder spraying should be selected.

If you are considering panels, pay attention to the polyurethane filler - it must be of high quality. Otherwise, after several years, the filler will begin to delaminate and lose its heat-insulating qualities.

Carefully inspect the joints between the elements. The parts at the joints should be made of high-quality wear-resistant polymer. Ask about additional reinforcements, among other things.

You should also make sure that the torsion springs are equipped with locking mechanisms that work when the door breaks. These mechanisms block the sash, preventing it from falling.

In humid climates, choose materials with corrosion protection. When buying, check with the sellers for warranty periods. Check if it is possible to equip the structure after manufacturing with additional burglary protection.

It is advisable to pick up the gates with an additional door for people if there is no side door in the garage. Electric gates of different manufacturers are equipped with traction belts, cables or chains to transmit movement. It is recommended to choose a model with a traction belt - it is more convenient to use, since the belt does not need to be lubricated.

The electric drive must be equipped with an automatic locking system, triggered when foreign objects get under the door leaf, and also with a device for slowing the movement of the leaf, which reduces the load when it is lowered.

Types of insulation of metal garages

According to SNiP 21.02-99, the start of an unprepared car engine and its comfortable storage in the garage are possible only at a temperature not lower than +5 ° С. This value should be taken as a basis. To ensure this requirement, the insulation must be laid on all internal surfaces of the garage after its manufacture.

If the insulation is presented in the form of rolls and sheets, when laying them, you need to pay attention to the joints between them. The sheets are lapped to each other and are interconnected by aluminum tape so that cold air does not enter through the slots. Especially carefully insulate the joints of the outer skin of the structure and the corners.

An additional door at the gate also plays a role in the insulation of the garage, since there is no need to open the door completely every time. When organizing a warm garage, if possible, choose a gate with such a door.

Insulation should be laid as tight as possible to metal structures. If this is not done, condensation will form in the space between the insulation material and the metal, which will provoke the development of corrosion and significantly reduce the service life of the garage. For this reason, in the manufacture of wave iron garages, it is desirable to use a liquid insulation that reliably envelops metal surfaces.

Start the process of warming a cold garage by choosing the right material. In the old days, there was no particular choice in the manufacture of car garages - most often foam was used. Today, there are many options that can be conditionally grouped into four main areas.

Polyfoam is still one of the most popular materials for the insulation of metal structures. This is mainly due to the affordability of polystyrene foam, but this material has other important advantages. Its plates are durable, when used in closed metal structures, they serve at least 25-30 years. In addition, the foam has moisture resistance. Of the significant drawbacks, it is worth noting its flammability, although a modern self-extinguishing modification of PSB-S is also produced.

The closest insulation material to the foam is extruded polystyrene, better known as foam foam in our country (since the Penoplex factory is engaged in its production). In many ways, this material has advantages over foam.

The screed can be poured onto the laid foam, its strength is enough to store the car on this screed. Compared to polystyrene, the level of thermal insulation of a polystyrene is about a third better: a sheet of polystyrene foam 30 mm thick is equivalent to a sheet of polystyrene 50 mm thick.

In terms of waterproofing, expanded polystyrene is also more reliable. While air can partially penetrate through the foam, sheets of foam can be laid even in water. The only significant disadvantage of this material is the price - it is almost twice as expensive as polystyrene. This is an important factor in the manufacture of metal garages.

- Cotton insulation.

Absolutely all fibrous heaters are vulnerable to moisture. Wetting about 1% of such a material reduces its heat-insulating qualities by 7–9%.

Cotton wool is not suitable for warming the metal surface, because the dew point inside the garage will be located near the heater. In such conditions, a hygroscopic heater absorbs moisture very quickly, even having protection in the form of a layer of paint or a plastic film.

Among the foam insulation the most popular polyurethane foam. The developers of this material declare its durability (50 years or more), high strength, moisture resistance and good thermal insulation properties. According to the latter, polyurethane foam is only slightly inferior to expanded polystyrene. Among the shortcomings, one should mention its high cost and the need to attract specialists (which, consequently, entails additional costs), since expensive equipment is unlikely to be necessary for applying a heater after the manufacture of a garage, which is unlikely for a lay man.

Penoizol is also used. It is slightly cheaper than polyurethane foam and is a liquid foam in cylinders. The only advantage of penoizol over slab foam is the absence of seams.

Nevertheless, it is not necessary to use polyurethane foam as the main insulation material in the manufacture of a metal structure, since its purpose is initially completely different. In addition, for insulation, for example, one gate will take from 5 to 7 cylinders, and foam insulation of the entire garage can completely empty the wallet.

Thermal insulation paint is a modern, expensive, but very simple way of insulation. Of all the existing liquid polymer insulation, this material is most known. Such paint can be applied to the surface of the building after its manufacture with a regular brush or roller. A paint layer with a thickness of 1 mm is equivalent in its properties to a cotton mat with a thickness of 50 mm.

At the same time, heat-insulating paint has fire resistance and moisture resistance. The minimum service life claimed by manufacturers is 10-15 years. The cost of 1 liter of material is at least 400 rubles. Considering that to cover 1 m2 of the surface with a millimeter layer, more than 1 liter of paint will be required, and in the case of a garage building, at least two such layers are necessary, you can roughly estimate the cost of such insulation.

Why should you contact us?

We respect all customers and equally scrupulously perform tasks of any volume.

Our production facilities allow us to process various materials:

- non-ferrous metals

- cast iron,

- stainless steel.

When completing an order, our experts apply all known methods of metal machining. Modern equipment of the latest generation makes it possible to achieve maximum compliance with the original drawings.

The advantage of contacting our specialists is compliance with GOST and all technological standards. At each stage of work, strict quality control is carried out, so we guarantee customers a faithfully executed product.

Thanks to the experience of our masters, an exemplary product is obtained that meets the most demanding requirements. At the same time, we build on a powerful material base and focus on innovative technological developments.

We work with customers from all regions of Russia. If you want to place an order for metalworking, our managers are ready to listen to all the conditions. If necessary, the client is provided with free specialized consultation.

Frame construction

Most often, structures with a frame are erected, which are subsequently sheathed with various materials. Among the advantages of frame structures, we note the following points:

- Going fast. As a rule, a metal profile is used as the main material when creating the frame. The connection of the individual elements can take place using screws or by welding. If screws are used, then the structure is detachable, due to which it will be possible to disassemble and transport it if necessary.

- If necessary, you can mount the structure on a monolithic slab or foundation. Due to this, the probability of a garage being lifted by intruders is excluded.

- All work can be done independently, this does not require a special tool or certain skills.

As sheathing material can be used:

- Plain sheet metal. Today it is extremely common, both in the form of black and galvanized metal.

- Decking is a metal sheet that has a galvanized coating with an additional polymer coating. In addition to this surface is given a shape that increases the rigidity of the sheet.

- The metal tile resembles corrugated board, but it has a slightly different waveform.

The advantages of this design include:

- It is possible to immediately create a niche for the placement of insulating material. In order to protect the room from cold and sound, insulation can be laid.

- The cost of construction is relatively low. Metal profiles and claddings are relatively inexpensive.

- You can do all the work, from start to finish, with your own hands. To do this, you need to have a small set of tools: metal scissors, grinder, electric drill, hammer and pliers. Most tools are always available.

- The light weight of the structure determines that it is installed both on the ground and on a low-bearing foundation. In most cases, a reinforced concrete slab is used as the foundation. This type of foundation has a shallow depth.

- The required ventilation cannot be provided. It is worth remembering that when the car is running, carbon dioxide is released. Many people warm up the car in the garage, due to which, without ventilation, the concentration of carbon dioxide rises.

- Gaps may form between the individual sheets of the casing, through which air enters the room. That is why it is necessary to conduct insulation of joints, which complicates installation work and increases the cost of construction.

When choosing a metal, attention should be paid to which has protection against exposure to high humidity. An example is corrugated board and metal tile - in their production, the steel sheet is covered with a zinc and polymer layer. Ordinary sheet metal is usually coated with a paintwork material, as otherwise corrosion will appear within a few months after installing the garage.

- The design does not have high insulating qualities. The temperature in the room during cooling is almost the same as outside.

- Relatively low resistance of the garage to wind loads.

- It is difficult to create a large garage due to the fact that the distance between the load-bearing elements increases, due to which the load on the roof increases.

In addition, the insulating quality of the metal is low. Therefore, it is cold in the frame metal garage in winter, everything that happens outside is heard almost immediately.

Frameless design

For a long period, frameless structures were installed. Today they are found less and less. The advantages of this type of garage include:

- High strength and reliability. When creating walls, stiffeners are created that increase the strength of the structure.

- Good surface insulation, as individual sheets are joined by welding.

- A similar structure can be transported. This is due to the fact that it can be lifted using a crane and put on a loading platform. Of course, the structure can withstand such a load only if there are a sufficient number of stiffeners.

- The cost of such a structure is relatively low.

But there are several significant drawbacks:

- The complexity of the work, as individual sheets are welded together.

- Stainless steel does not weld well. Due to this, installation work becomes much more complicated or you have to use ordinary metal.

- No ventilation. As previously noted, good ventilation is important for garages. It is designed for exhaust gas and fresh air.

- In most cases, the roof is flat, since it is practically impossible to create a gable and gable roof without a frame. Even with stiffeners, heavy precipitation in the form of snow with its accumulation will lead to roof deformation.That is why you should periodically clean the roof in order to avoid problems.

In conclusion, we note that some companies sell kits for self-assembly of a garage. Due to this, installation is greatly simplified and accelerated.

Advantages and disadvantages

Many car owners prefer metal garages.

This is due to several advantages of these metal structures:

- Resistance to fire. Metal does not burn at all and does not support combustion, which makes it completely safe in the event of fires.

- High strength. Thick and high-quality metal structures are hard to crack. But these indicators are slightly worse than those of monolithic brick structures.

- Relatively low cost. The price of a garage depends only on the method of its manufacture and the quality of the metal. In most cases, these indicators are much lower than in classic monolithic buildings made of brick or gas blocks.

- The metal structure is not legally considered a monolithic structure. Therefore, these structures can be easily erected without the availability of specialized documentation.

- Speed and ease of installation. You can design such a building even without certain experience. Today on the market there are several varieties of prefabricated metal garages. They only need to be assembled correctly by connecting all the elements according to the manufacturer's instructions.

- Relatively light weight. If necessary, a building made of metal can be moved, which is impossible for monolithic structures.

But metal garages are not universal designs.

Such systems have several significant disadvantages:

- The minimum level of thermal insulation. Metal does not retain heat well: it is rather difficult to work inside them in winter. Therefore, many experts recommend additionally insulating the walls with various materials. Non-insulated garages are quickly cooled and heated, which also leads to the formation of a large amount of condensate. He, in turn, has a bad effect on metal structures and automobiles.

- Inability to install electricity. This is due to safety precautions. Theoretically, a current can be brought in, but if it is produced only by its own generators.

- Low fire safety. The metal itself does not burn, but heats up very quickly, and the presence of gaps can lead to the penetration of fire from outside into the building, with subsequent damage to the car and all other property.

- The minimum level of protection. This applies to structures that are installed on a soil or asphalt surface and are not attached to it. Some craftsmen can simply lift the structure with a jack, prying one of the walls. Metal substrates are also well destroyed by the grinder and special circles. Therefore, in terms of safety, a monolithic design is much better.

Constructions

The construction of any metal buildings requires preliminary calculations of all technical parameters. To do this without certain skills is not always possible. But simple modifications can be calculated independently. Depending on the design of the structure, metal garages can be divided into several subspecies:

- Factory buildings. Garages of this kind are in most cases collapsible and portable. To assemble such a product, you will need to stock up on only a few types of wrenches, a hammer, factory drawings and other auxiliary tools. Among the advantages, practicality and durability can be highlighted. But the cost of such a design is much higher than an independent construction. The sizes of garages often do not exceed a one-story building.

One of the varieties of these garages is used construction, which can be purchased at various trading floors.

Their prices are already much lower than for new modifications, and it is also possible to export them from a specific place on their own.

- Garages built by hand. These buildings are distinguished by unique technical properties and dimensions. Some owners make two-story structures that allow you to use them as an additional storage location. Many modifications are monolithic, as they are firmly fixed to the concrete foundation. Please note that here welding is already used for the connection. This approach allows you to get a durable system that can withstand loads for a long time. But self-assembly of a garage requires specialized skills for working with different tools. Therefore, it should be carried out only by specialists who are able to correctly calculate all the parameters.

Preparatory work

The construction of any structure involves preliminary planning. This will eliminate a lot of unforeseen situations and create a strong and durable building. Installation of a metal garage involves the implementation of such preparatory operations:

- Choosing a place for construction. It is desirable that the garage is located in a convenient place for moving the car. If you have a private land, then you can install it right next to the road. In another case, it is desirable to ensure the optimal arrival of the vehicle. Metal garages need to be installed remotely from a residential building and only on high ground. If the structure is constantly flooded with melt or groundwater, then it will quickly rust and become unusable.

- Foundation preparation. Before starting work, it is advisable to remove the top layer of chernozem, as well as level the soil. This will simplify all other installation work.

- Design. There are no universal recommendations. The dimensions of the garage should be such that your vehicle fits easily inside. If you plan to carry out repairs in this building or store spare parts, then the parameters need to be increased taking into account these requirements.

- Purchase of building materials. To build a garage, you will need a lot of thick metal sheets, profile pipes, as well as a welding machine, bolts, screws and other fasteners. If you plan to make a warm building, then you need to take care of purchasing a certain amount of heat insulator (mineral wool and more).

Mounting

Building iron garages is a relatively simple operation. But to do it only with your own hands will not always work. All work is best done with several helpers who will not only help bring the materials in, but also hold the structure during assembly.

The installation of garages begins with the arrangement of the foundation. It is undesirable to install the structure only on compacted soil, since it will contribute to the development of corrosion processes.

For this structure, you can use several types of bases:

- Monolithic foundation. This type of construction perfectly tolerates all kinds of loads. But it is not effective to use it for such light buildings, unless the foundation has already been built under something.

- Floating foundation. Good and inexpensive option. For the construction of such a foundation, several reinforced concrete slabs should be laid on pre-compacted and leveled soil. The installation of these elements is carried out by a crane, which in turn increases financial costs.

- Strip foundation. The best option for metal garages. Building it is relatively simple. Initially, a channel is rummaged around the entire perimeter of the future building. The depth of the trench should not exceed 50-80 cm, as this is enough to support the light weight of the garage. After that, sand and gravel are poured onto the bottom of the ditch, then everything is rammed. To improve strength, you can put granite stone here, and then pour it with a liquid cement mortar. A formwork is mounted on top, which is already filled with concrete. The height of the support is selected individually depending on the needs of the owner and soil characteristics. But to make too high formwork is not recommended, as this will increase the volume of materials for leveling the floor.

The metal construction construction algorithm consists of the following sequential steps:

- Frame construction. Outwardly, it resembles a box, the walls of which are reinforced with additional posts. From the side where the gates will be located, they build a kind of internal frame for these structures. Pipes are connected together by welding. If you do not weld the profile, but fasten it together with bolts, then small fluctuations will appear over time and the design will not be so strong.

Profiles should be further strengthened with braces, metal corners and other similar elements.

The roof can be single or double. If the second option is preferred, then it is necessary to ensure the possibility of fastening the metal structures to the main frame. The construction of this system involves the manufacture of frames in the form of triangles, and then fastening them to the main supports. Logs are connected with each other using metal jumpers.

- Sheathing. This step is relatively simple. Start wall cladding from one of the corners. To do this, the metal sheet is welded or screwed to the frame. The second option is used together with professional sheets, which can be selected for any dimensions of the building. When covering, it is important to completely eliminate the presence of any gaps. Therefore, you need to monitor the density of the joints, where they form. If a profiled sheet is used, then it is superimposed on one another. In the case of welding, the joints are qualitatively boiled or closed with additional metal plates.

- Gate installation. The pre-prepared metal frame is adjusted to the dimensions of the opening. Hinges are welded to both elements, on which the wings are then suspended. It is important that the gates completely cover the opening and prevent air from entering the garage.

- Warming. This step is not required, but it is carried out almost always. For this, sheets of mineral wool are used, which are located between the profile pipes from the inside. It is important to close them with a plastic film so that moisture does not penetrate into the structure of the material. After laying cotton wool, it is sewn up with metal sheets or other decorative materials.

Tips & Tricks

Installation of metal garages is a long and laborious operation.

To get a quality and durable design, you should be guided by several rules:

- Use only high quality metal. It is undesirable to use elements damaged by corrosion, as this will lead to a very quick repair of the product.

- Be sure to coat the metal with protective primers and paint. If this is not done, rust will form very quickly on the surface.

- When insulating the garage, do not place electrical wiring inside the insulation.

- To simplify repairs, you can build a survey hole inside the building. It is advisable to plan its presence in the initial stages.

- Install several locks on the gate to complicate the breaking of the structure.

Metal garages are universal and practical structures, which with competent construction can turn into a full-fledged place for storing and repairing a car.

See how to make a metal garage with your own hands in the next video.