A wooden table leg can be not only a functionally necessary furniture element, but also become its real decoration. The most interesting and creative ideas for decorating wooden legs will be discussed in our article.

Material benefits

Wood is a material that has been preferred since ancient times. And this is no coincidence. It is easy to process, which allows you to give the finished product a wide variety of forms. Another advantage of wood is safety for human health.

For the manufacture of furniture supports use different types of wood:

- The oak is considered the strongest. He is not afraid of high humidity, temperature changes, does not rot. The processing of such wood requires special equipment, which leads to the high cost of the finished product. Over time, the oak becomes deeper.

- Moisture resistant is also a nut. Its advantages are light polishing and high strength. However, in order for the tree to retain its impeccable appearance for a long time, processing with a special agent that prevents the appearance of rot is required.

- A beautiful shade belongs to beech. The tree is very durable, but not moisture resistant.

- Tropical wenge wood is another popular option. The finished product is resistant to mechanical stress, so for a long time it retains its perfect appearance.

- Mahogany has high characteristics. The only drawback is the too high cost.

Production process

Wooden legs for tables are made by several methods:

- Using lathe the workpiece is mounted on a support. The machine cuts out the desired shape, while the workpiece rotates around the axis at high speed. The advantages of such legs are ease of production and, accordingly, low cost of the finished product.

- Milling method allows you to perform original and very beautiful products. The milling machine displays the pattern and shape according to the parameters entered into the program. This method is relevant when processing expensive wood species, where chips and marriage are unacceptable. Using multi-axis milling machines, carved legs are made that look very impressive and luxurious.

- Despite the widespread use of modern technology, manual labor not sunk into oblivion. Until now, craftsmen have carved stunning home furnishings from wood. Manual labor is laborious and time consuming. Therefore, such products are quite expensive.

Design features

All family members gather at the dinner table. He is a symbol of the family hearth. The number of wooden legs at the table can be very different:

- One leg. A characteristic design feature of such models is massiveness. Indeed, in order for the countertop to remain stable, the leg must be powerful and large. This option looks good with round and oval models.

- Two pillars. Ideal for an oval-shaped table. The design is stable, as the legs end with an extension that increases the area of the support. As a rule, two legs are connected by a jumper. It can be located both in the upper and lower parts. Particularly spectacular look models that are equipped with a carved jumper.

- Four pillars. This is the most common option. The legs of such tables can be original, with carved inserts. A special niche is occupied by laconic tables, in which the legs are rectangular bars, devoid of any decor elements. This technique is relevant for high-tech, country styles.

Stylistic solutions

The shape and style of the legs can be very diverse. Most popular are:

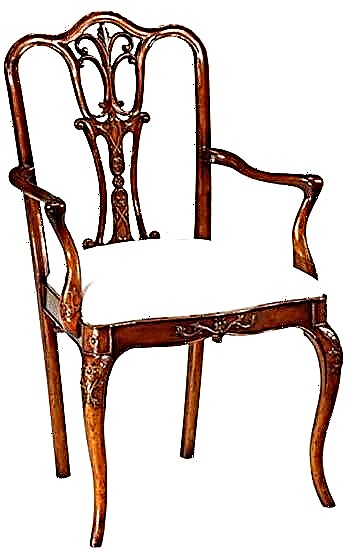

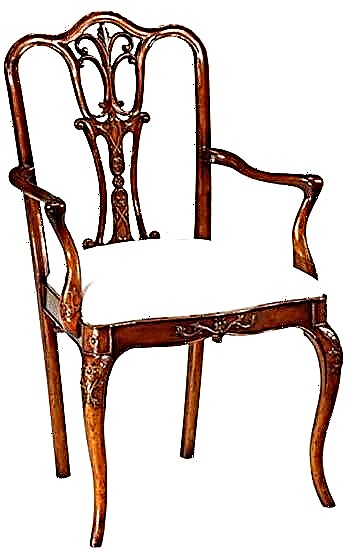

- Cabriole. In shape, such a leg resembles a wave with two bends. The leg is as if formed by two arcs located opposite to each other (one smoothly flows into the other). Roundness, grace - the characteristic features of the convertible. Style was an indicator of luxury and wealth in the 18th century.

- Empire. Style came to us from antiquity. Its feature is the presence of a relief ornament. Often the legs of the tables are made in the form of the clutches of fabulous creatures - griffins or female figures. For the manufacture you will need dense wood, not giving chips.

- Victorian era. Such products are very beautiful. They often contain plant elements. Elongation of forms, symmetrical ornament, gilding decor are the main features of the style.

- Geometric style. Its basis is the correctness of forms and simplicity. The conical leg can be supplemented with a ball or a triangle. Sophisticated decor, carved elements in these models are missing. This table is perfectly combined with the interior of a modern apartment. Geometric elements perfectly emphasize the styles of minimalism and hi-tech.

- Combined style. Designers often use several styles, creating their own masterpieces, which gives the product a special touch. Geometric shapes are well combined with carved decor elements and curved lines.

Design options

Using various decor methods, you can turn the table leg into an exclusive, which none of your friends and acquaintances will have:

- Using a chisel or other sharp object, patterns and ornament are cut out on the surface. This technique is called carving.

- Incisors, mother of pearl and ivory are necessary for inlaying.

- Individual elements of the legs can be coated with gold leaf, copper or bronze.

- As a coating for wood, varnish is used. Often used several of its layers. With antiques, their number can reach up to 200.

Stylish design tricks

Especially popular are designer designs that are non-standard and original:

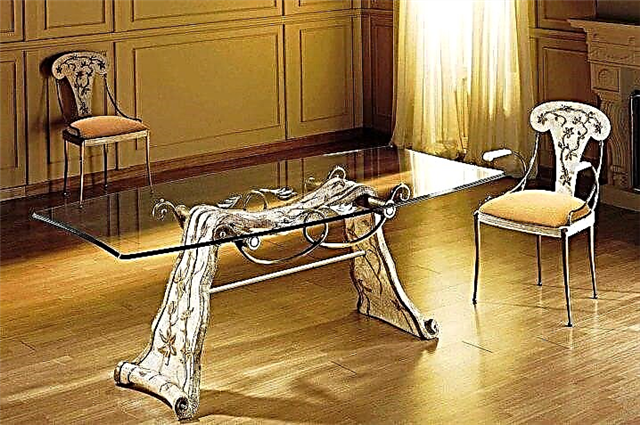

- A round table made of glass and wood will help to give the living room an unusual, but at the same time modern look. A transparent worktop rests on three double wide legs of irregular shape. Glass gives lightness, airiness and at the same time allows you to see the pattern of wood.

- An interesting trick is the use of bright colors. If the legs at the glass table are made to match the kitchen interior, they will become a color accent, in harmony with the facade of the furniture. Randomly located, they will give originality.

- Coffee tables are an essential attribute of any living room. In addition to the fact that they have a beautiful appearance, their dignity is functionality. Niches, all kinds of shelves allow the owner to place various useful trifles inside the table.

- Particularly interesting are the tables in which the tabletop flows smoothly into the legs.

Wooden legs can turn a table into a real work of art. At the same time, designers use the most incredible forms.

How to do it yourself?

DIY furniture is exclusive. Plus, the flight of fancy is unlimited. Therefore, you can experiment and to make a stylish original little thing with minimal effort:

- The sketch must first be transferred to paper. You can use your own version or apply what you saw and like. Do not forget that the length of the legs at the dining and coffee table is different. The simplest form of legs is whetstones.

- After measuring, proceed to the procurement of material. Get a little more wood than was estimated.

- Finished legs must be polished so that the surface is absolutely smooth and does not injure the skin. Use varnishes and impregnations that protect against moisture.

- It’s not necessary that the legs at the table should be traditional. Take advantage of the small long bars. Fold them in a chaotic manner, fastened with self-tapping screws or wood glue. Place a glass top on top of the structure. The combination of glass and wood will give an amazing effect.

For giving you can build an unusual, but comfortable table, the leg of which is an old stump. Note that the stump should be dry, without rot and damp. It is cleaned of bark and soft particles.

Align the stump with respect to the horizontal plane using the level. The surface of such a peculiar leg is ground, varnished. The wooden tabletop is fastened with self-tapping screws or nails. If you use a tabletop made of transparent glass, the product acquires a special style and effect. It will become a real decoration of any living room.

See how to make wooden legs with your own hands in the next video.

Manufacturing Features

Wooden legs for furniture are presented in a large assortment; they differ in the method of manufacture, style, shape, size and type of wood. In many respects, the final price of finished products depends on these parameters. Also, in the formation of value, it matters whether the work will be standard or custom-made.

The most common are the following methods of decorative processing of furniture legs:

Turned furniture legs

The simplest and most inexpensive products are made by turning the blanks on a lathe. The shape is attached to the parts during rotation of the fixed product on the machine.

Turned carved table legs

Turned carved table legs

The main tools used to grind a curly surface on wooden legs are flat and semicircular chisels.

With the help of simple fixtures and without laborious work, you can make beautiful furniture legs with attractive smooth lines. Processed wooden products can have a wide variety of geometric shapes. Most often these are cylindrical, cone-shaped, drop-shaped and spherical parts. Such products look very harmonious and at the same time their price is affordable to everyone.

Milled Products

Original wooden furniture legs are made by milling.

The process of manufacturing a milled leg

The process of manufacturing a milled leg

The basis for such products are already finished turned products. The turned part of a cylindrical, rectangular or other shape is additionally decorated with various patterns, recesses, grooves and ornaments of geometric type.

Work on the manufacture of decorative furniture legs is carried out on milling machines. As cutting devices, a large number of different knives, cutters, discs and milling heads are used. Modern machines allow you to program products of any complexity. This allows you to significantly accelerate productivity and reduce labor costs in the manufacture of parts.

Carved furniture legs

The most interesting and original are carved legs. If earlier exclusively manual labor was used for the manufacture of carved objects, now multi-axis milling machines are used. Although handcrafted woodcarving is still appreciated more. Unique furniture with carved legs compares favorably with other products and is considered an indicator of the special status of the owner.

The process of manual manufacture of carved legs is very difficult and requires many tools and cutters of different configurations, as well as great experience and talent from the master.

If wooden carved legs made on expensive equipment have a considerable cost, then handmade products are sometimes valued on a par with works of art. The automated manufacturing process of carved legs involves the use of a copy-milling machine.

The principle of its work is the use of a three-dimensional template of any material: wood, plastic and so on. The three-dimensional model is installed on the machine and a special cutter completely copies the contours of the model in all planes onto a wooden blank. This method allows you to get many identical products in a relatively short time.

Advantages and disadvantages of carved wooden legs

Carved elements of the interior look great in various styles: classic, chalet, gothic, baroque palace style, French country style, ethnic or vintage. Wooden legs from a carved massif for decorating furniture have the following positive aspects:

- environmental friendliness and harmlessness of the material,

- durability with the right choice of wood and maintaining a stable temperature and humidity,

- a return to their origins and traditions,

- the uniqueness and originality of the interior,

Various options for carved furniture legs

Various options for carved furniture legs

It is also worth considering the disadvantages of carved wooden legs:

- it is important to organically combine furniture with carved linings in the interior,

- the tree is sensitive to moisture and temperature changes,

- cleaning carved elements has a certain complexity,

- high price.

Varieties of carved legs for furniture

Depending on the general form and style, the following types of furniture legs are distinguished:

- Cabriole. The carved leg of the cabriole features a recognizable double bend. Thicker upper bend and thinner lower. In this case, the axis of the legs is located in one plane. Cabriole legs are very elegant and light. Their appearance dates back to the Rococo era, when they replaced the fashionable and heavier furniture legs in the form of animal paws.

- Empire style furniture legs. In the design of furniture legs of the Empire style there are motifs of ancient times: sphinxes, griffins, lion paws. Therefore, these legs often looked like the paws of an animal, and the upper part of the support was crowned with his head.

- Victorian classic. The decorative elements of this style are characterized by symmetry, elongated shapes, straight or curved lines. Carved ornaments have plant motifs. Victorian style - an English classic, a combination of respectability, good taste and luxury.

- Geometric shapes. The modern type of carved legs are products with simple geometric shapes. They are characterized by strict lines of volumetric figures - a cone, a cube, a ball, a cylinder.

- Combined type. These products are a combination of geometric shapes with more complex forms of thread.

Example of Combined Carved Feet Back to the table of contents

Example of Combined Carved Feet Back to the table of contents

Materials for the manufacture of furniture legs

Since the legs must sometimes withstand significant weight of furniture, they are made of solid wood: oak, ash, beech. If finances allow, you can buy high-strength products from such elite varieties as walnut, wenge, mahogany.

- Oak. One of the most popular types of wood - it is widespread and is characterized by high strength and hardness. Oak is resistant to temperature changes, humidity and putrefactive processes, it is durable, has a beautiful, noble texture. The price of oak products is quite high. Hardwood is difficult to process and polish and requires tools with high-tempering cutters.

- Ash. The characteristics of wood are in many respects similar to oak, only the structure of ash is lighter and less pronounced.

Carved table legs made of ash

Carved table legs made of ash

Ash has unsurpassed strength and hardness, does not crack during drying, and easily bends. Products from this breed of wood must certainly be treated with antiseptic agents, because in conditions of humidity, wood has a tendency to wormholes.

Cracking may occur if improperly dried, but if the technology is followed, the dried wood is very strong and keeps its shape perfectly.

Cracking may occur if improperly dried, but if the technology is followed, the dried wood is very strong and keeps its shape perfectly.The cost of carved wooden furniture legs

The price of wooden carved legs will vary depending on the type of wood, size and processing method. Also, the final cost of the product will be affected by such additional measures as grinding, polishing, painting:

- economy - milling and partial grinding,

- prestige - milling with detailed manual grinding,

- extra - milling, manual grinding, detailed threading.

| Height (cm) | Product Processing Method | Wood species | Price of products (rub.) | ||

| Economy | Prestige | Extra | |||

| 90 | Carved | Beech | 5600 | 8000 | 11200 |

| Oak | 5800 | 8500 | 11700 | ||

| 85 | Chiseled | Beech | 2100 | 2700 | |

| Oak | 2400 | 2900 | |||

| 16 | Carved | Beech | 1600 | 2400 | 3500 |

| Oak | 1800 | 2700 | 3800 | ||

Turned and milled products of a simple shape, which are required in large quantities, it is quite possible to buy prestige and economy in the variant.

Decor option for carved furniture legs

Decor option for carved furniture legs

It is better to buy more complex piece furniture legs with complex carving in the extra-class version. So you can be sure of the detailed study and quality of the product.

Carved table legs made of ash

Carved table legs made of ash