What role does drywall glue play in wall treatment with this material? Why is the gluing method better than mounting on a frame base? What can be used as an adhesive mixture? We will consider these and other questions in our article.

General information

Drywall is a popular material for leveling walls. Its use guarantees perfect evenness of the walls, strength and resistance to physical impact. Drywall is environmentally friendly, as it is made from natural components - gypsum and cardboard. It can be installed in two ways: on the frame base or on glue.

What is the advantage of the second method:

- The frame captures a lot of space, and the glue saves it, which is important in tight rooms.

- No need to spend extra money on screws, fasteners, and other related parts.

- Work is done easier and faster.

The outer layer of drywall is kraft paper. Its porous surface provides reliable adhesion to most binders. Therefore, the choice of glue for GCR is quite large. Before buying, you need to make sure that your type of drywall sheet allows for installation on glue. At first glance, it seems that working with glue is quite simple, but this is not entirely true: it is important to follow the procedure, take into account the setting time of the glue, carefully attach the sheets to the surface.

Types of drywall glue

There are many types of adhesive mixtures, and everyone has different recommendations for use.

What is the glue for drywall:

- mounting,

- gypsum-based mastic,

- specialized,

- liquid Nails.

Assembly mixture - dry powder, which is diluted in water.

Advice! Always pour the mixture into water, and do not pour water into the mixture. The first method is better, since the glue is uniform in consistency.

Installation glue sets quickly enough, therefore, correction of installation irregularities can be made within 10 minutes. The positive properties include moisture resistance. This allows the installation of drywall in places with high humidity.

Mastic - a mixture of gypsum and glue. First, the glue is poured with water and left to swell for 15 hours. Then lime is added to the glue, previously diluted with water to a thick consistency. Then gypsum is added. The mixture has good setting properties - from 40 to 50 minutes. For the installation of gypsum plaster, you can also use gypsum-sawing mixture. It is prepared as follows: sawdust and building gypsum are mixed in a ratio of 1: 4, then a glue solution is added (25 g of dry matter per liter of water).

Special adhesive for drywall is used only in case of minimal differences in height. Its feature is a quick grasp. One cylinder (750 ml) is enough for an average of 15 sq.m. It is acceptable to use liquid nails, but this is an expensive method.

What else can be used as glue

Polyurethane foam is comparable in price to cement mixes, however it is not so convenient in use. With a large distance between the drywall sheet and the wall, it will be necessary to solve the problem of expansion of the mounting foam. Each sheet needs to be fixed with dowels, and this is not always convenient.

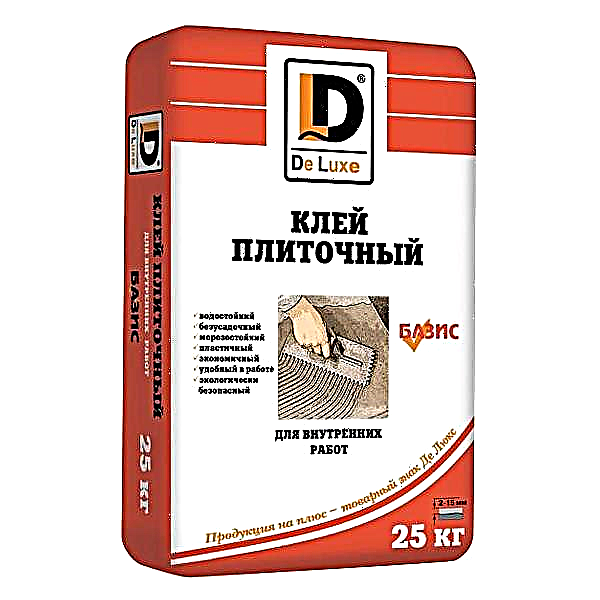

Tile adhesive. Originally intended for ceramic tiles, the composition began to be used in the installation of drywall. Such glue has moisture resistance, cold resistance. It is also environmentally friendly. Acrylic putty and sealants can also be used for the installation of gypsum plaster. They provide a strong connection with a minimum thickness of the seam.

Which to choose

The choice of adhesive mixture depends on the surface on which the drywall sheet will be installed:

- For a brick wall and any other uneven surface with wide seams, gypsum drywall adhesive is suitable.

- For concrete, gypsum and cement adhesives and polyurethane foam are equally suitable.

- Gypsum plasterboard can also be glued to foam or thick foam. Use mounting foam or acrylic putty for this.

- If the drywall is glued to the drywall, then it is not necessary to compensate for the unevenness of the base. This means that any adhesive mixture with a minimum thickness of the seam will do. You can use liquid nails, silicone sealant and acrylic putty. Cement and gypsum composition can also be used, however, they increase the thickness of the seam.

Why exactly glue?

This mixture is sold in almost all construction stores, so there will be no problems with its choice. We will tell you about all types of glue that can be used for fixing drywall. We will explain in detail about the characteristics and features of each type of glue, so that it is easier for you to decide on its choice, thereby ensuring high-quality manufacturing of the entire structure.

The main advantage of the adhesive composition is the ability to quickly and easily connect drywall with the wall surface, without using screws, screws, wall plugs. Also, if you decide to use glue, then you do not have to make complex skeletons of the product, but only if you just need to sheathe the surface with GKL sheets. For example, if you want to finish the bathroom with moisture-proof drywall, but it is small and the frame will reduce them even more, then in this case using glue is the best solution to this issue in terms of effectiveness.

Preparing the wall surface for gluing

In order to ensure reliable adhesion of the glue to the wall, you need to clean it from dust, dirt, pieces of paper. The surface should be smooth and even, otherwise there will be no good adhesion. Also, you should understand that if the walls have a large difference in height (1-2 centimeters is the norm, everything that’s bigger can already be considered roughness), then it’s better not to use glue for such a surface, but think about other ways of fixing, for example, using the frame.

If the wall has been painted, then the paint must be removed, but it must be done carefully enough, as there may be small pieces of paint that will be difficult to tear off the wall. In the event that there is no paint on the wall, and the wall itself is new, then it is necessary to carry out a primer on it to level the surface and improve adhesion to the paint layer. The better and more thorough the primer will be carried out, the more reliable will be the fastening of drywall to the wall.

It is necessary to put a mark on which the first sheet of drywall will be installed. To do this, you need to measure the distance from the beginning of the wall, which will be slightly larger than the width of the GKL sheet (for glue), and then draw a line in this place along which you will stand the sheet. Further sheets of drywall are attached, focusing on the previous one, or according to the above principle. If you have worked well on the surface, and you think that the glue will adhere well to it (according to the previous requirements), then in this case you can begin to solve the problem of how to glue drywall.

Types of glue, differences, methods of application

There are many types of glue that are used when working with drywall. We will talk about their most popular types, which will be quite simple for a beginner to use, but in terms of functions and quality they will not be inferior to expensive professional mixtures. In general, the mixtures used to install drywall sheets on various surfaces are divided into:

- Gypsum-based mixture (mounting adhesive). Most mixtures of this particular type, since they are very versatile and easy to use and prepare, we recommend that they be used in work, both for beginners and experienced specialists,

- Silicone glue. This mixture is used in cases where you need to glue a sheet of drywall to smooth and glossy surfaces, but this is an optional condition for its use. Silicone can also be used for fastening to an ordinary concrete wall,

- Putty. In general, this type of mixture is used to process drywall at the final stages of work, but it can also be used to fasten gypsum board to the wall. The main thing is that the putty can support the weight of the sheets.

You can consult with a specialist, but if you yourself understand the field of repair using drywall, you will probably be able to choose the best option for glue. In the event that you are a beginner who just wants to stick drywall to the wall, we recommend using glue for knauf drywall. It is very versatile, contains gypsum fibers that allow it to retain heat well. Also, this glue can be found in any hardware store, as it is very popular among specialists of all levels and qualifications.

In principle, there is not much difference by which it is possible to clearly separate the options and reasons for using this or that type of glue. Specialists often have preferences in this, but if you are just starting to work with drywall, then you should pay attention to the gypsum-based adhesive, since it is very convenient to use, you do not need to knead for a long time and wait for it to dry.

Gypsum Board Bonding

For work you will need:

- A bucket or any other vessel in which the mixture with liquid will be diluted,

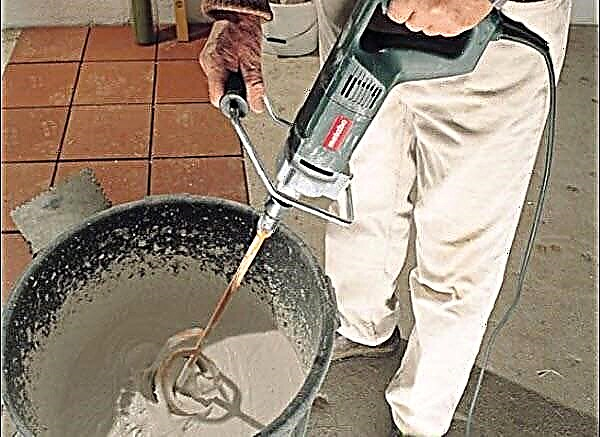

- A drill and a special nozzle that will allow you to mix the composition in a bucket,

- Putty knife, choose the width according to your preferences, we recommend using a wide spatula, since it is very convenient for them to apply the composition to the sheet,

- The construction level, so that it is possible to measure the wall for bumps,

- Glue for Knauf drywall, which will be the connecting link between the wall and drywall.

You can apply glue in any way. But we recommend applying it after all to a sheet, and not to a wall. This is due to the fact that the adhesive applied to the wall will hold the sheet in the position in which you placed it on it. And if a sheet of drywall, with an adhesive layer applied to it, is applied to the wall, then later you can slightly adjust its position, which is especially useful for those who are just starting to work with drywall.

Also, the geography of the location of the glue on the drywall sheet itself may make a difference. Most often, they just take a full spatula of the mixture, after which they spread a little on the sheet. Thus, pieces of glue cover the entire sheet evenly. But some experts noted that it is necessary to apply glue in even lines along the contours of the sheet, and then draw a few more perpendicular lines in the middle of the drywall. The step should be about 30-35 centimeters, thick lines do not need to be done, since the glue will greatly creep out of the sheet after gluing.

So, you need to spread the glue for drywall in your container with your own hands, based on such data: if the walls have some irregularities, then the consumption of glue for drywall will be about 1.3-1.5 kg per square meter of surface. That is, the approximate consumption of glue per 10 square meters will be 4-6 kilograms, but this is only subject to very smooth walls, and this rarely happens.

Glue needs to be diluted for 30–40 minutes of work, since then it just freezes, but keep in mind that after you have spread the glue, it needs to be allowed to infuse for 3-5 minutes. If you start immediately applying the glue, then its qualities will be much worse than that of the glue that was given to infuse. It is necessary to pour a gentle amount of the mixture, which can be determined according to the above rule, into the container. Then we pour water there, on 30 kg of dry mix, for example, such as the often used adhesive for drywall perlfix, about 15 liters of water are required. Be sure to carefully move the mixture for 3-4 minutes, for this use a drill and a special nozzle for it.

Put the finished mixture on a drywall sheet, if you have enough composition, you can completely cover up the sheet, just do not make the layer too thick, otherwise the sheet will become too heavy. So much so that even a large amount of glue will not hold him in one position, and he will begin to move out. The sheet of drywall on which the adhesive is applied must be applied to the wall, and then check its evenness with the help of a long and even rail, if something is uneven, you can correct the sheet. The main thing is to do it without delay, since the glue may already seize.

All subsequent sheets, which will be attached to the wall, must be exactly aligned with a rail, and then check the result with a building level. In this procedure, everything is very easy, even a completely newbie will cope. But you can not use glue in any situation in which drywall is used, if you want to make a more serious product, for example, a fake wall, then you still have to create a frame.

When GKL Adhesives Are Used

Cases when the fastening of drywall sheets to surfaces is best done by the adhesive method:

- When aligning capital walls with the size of differences, blockages and other irregularities up to 50 mm. However, with extensive potholes, the cost of too much glue can exceed the cost of the metal frame and make the venture economically disadvantageous.

- When leveling the ceiling. But in this case, while the glue is set, the gypsum board must be securely fixed so that it does not collapse under its own weight. They will solve the problem of dowel-screws.

- At registration of door and window slopes.

The glue can be used to fix the second layer of drywall with a 2-layer sheathing of the frame or crate, but this is rarely practiced: using screws in this case is faster and cheaper.

Drywall glue: which one to choose?

The list of types of adhesives recommended for fixing drywall is quite extensive:

- Specialized glue (Perlfix from the German company Knauf, Ceresit, Russian analogues Volma and Montazh).

- Plaster or putty, based on gypsum. In terms of price, adhesion to the surface to be glued, and the degree of shrinkage when setting, there is practically no significant difference with specialized adhesives for working with gypsum board.

- Hard putty made of acrylic. It is used when a subsequent tiling is planned. The composition keeps the walls from mold, the harmful effects of fungi and high humidity. Drywall is attached to it on a base of wood, shell rock, stone and foam blocks.

- Polyurethane mounting adhesive in an aerosol can. Ideal material for installing gypsum board and gluing seams with curved walls. With it, you can align the ceiling, attach ceramic tiles. To work with him, you need a special gun that provides an economical solution consumption.

- Low expansion coefficient foam replaces adhesive.

- Tile adhesive. Its mobility and fine-grained filler make work convenient and quick.

- Sealant. Any type of sealant replaces the adhesive designed for gypsum fiberboard, in addition, it allows you to process joints, corners, close gaps, making them impervious to moisture.

- Liquid Nails. Strong adhesive, safe for health, but requiring drying time and designed for a load of up to 15 kg. It is quite suitable for the sticker is not the thickest drywall.

Note! The mixture for fixing GKL from Knauf requires professional skills, work should be carried out without delay, since the glue hardens quickly.

How to glue drywall on brick, gas and foam concrete

With an uneven surface with wide seams, which is distinguished by masonry of brick, foam and aerated concrete, it is convenient to stick sheets of drywall with gypsum glue or any other gypsum mixture.In addition to a qualitative result, the plus is profitability: usually 5 kg of Perlfix are consumed per 1 m², the price of which is 300 rubles. per 30 kg bag.

Cost-comparable with gypsum adhesive, inexpensive mounting foam. A 750-millimeter balloon for spot application is enough for 8–10 m², the cost of a square is 30–40 rubles. However, here, with a large gap between the gypsum wall and the wall, solving the problem of expanding the foam, you will have to additionally attach each sheet with dowels.

Foundation preparation

Before gluing the drywall directly, the surface is primed, strobes for electrical wiring are made. When masonry, serious attention is paid to eliminating its inherent cracks and irregularities. For this, leveling putty mixtures are used. In some cases, to eliminate defects, you can stick GKL strips and mounting tape.

Foam and gas blocks usually do not create similar problems, however, there are damage due to careless transportation and unloading. They are eliminated with a gypsum mixture.

What adhesives are required for concrete floors

Typically, monolithic walls do not have obvious irregularities, the GKL sticker on them goes seamlessly and quickly. For this purpose, you can choose:

- gypsum adhesive for plasterboard sheets,

- plaster putty,

- acrylic putties,

- cement adhesive for gluing tiles,

- polyurethane adhesive

- polyurethane foam.

Each tool with a minimum size of the glue line will provide a strong connection of drywall with concrete.

Impeccable technical characteristics of "Concrete Contact" - primer, which includes acrylic polymers, cement, quartz filler. Its feature is special additives and additives, guaranteeing reliable contact with the most difficult and dusty surface than concrete usually sins with.

When the base is polystyrene foam

Polyfoam, expanded polystyrene protect the housing from the cold, but to prevent the destruction and preparation of the walls for finishing, they require closing them with drywall. As a rule, foam lining of the room steals 5 or even 10% of the usable area. If the plus is to place drywall on the metal profile, the loss of space will be even greater, so the GKL sticker here is the best option. Successfully cope with the task:

- drywall adhesive foam,

- acrylic putty.

GCR and gypsum fiber

Sometimes it becomes necessary to stick GCR onto a similar plasterboard or gypsum fiber sheet. There are no irregularities on such grounds, so any adhesives that give the minimum size of the seam are suitable for work. It can be:

- acrylic putty,

- liquid Nails,

- silicone sealant.

Suitable materials are foam, gypsum and cement adhesives, but the thickness of the seams when using them will be greater and will cause irrational reduction in the space of the room.

Option No. 1 (for flat walls)

It is used for walls without differences (usually concrete or plastered surfaces).

- The walls are dashed, the cable is fixed in the grooves made, holes are made for sockets and switches.

- A primer is applied to the dust-free surface. If the wall is painted and the adhesive does not stick, the composition with quartz filler solves the problem.

- In GKL, holes are cut out for electrical equipment.

The adhesive composition should be prepared on 1-2 sheets, especially at first, when there is no necessary dexterity.

- Gypsum-based glue is applied to the GCR with a notched trowel, the excess is removed. If another composition is used, for example polyurethane adhesive, it can be applied in stripes or as shown in the photo.

- The sheet is placed near the installation site face down.

- Before the sticker, it is carefully lifted and the wires are guided into the prepared holes.

- The sheet is effortlessly applied to the wall, using the rule they find places where the material should be denser attached to the surface, achieve this by tapping the sheet with your hand or by applying the board and lightly hitting it with a mallet. Knocking on the level is not worth it - it is an accurate tool that will fail before the floors become even.

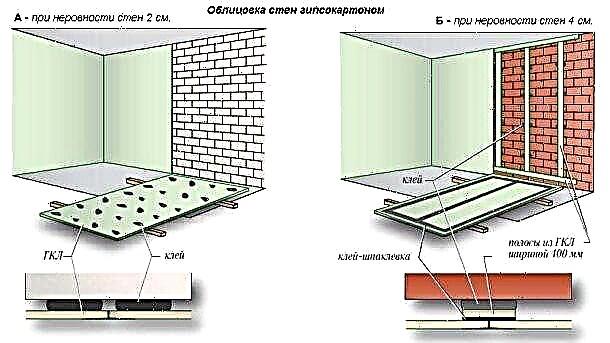

Option number 2 (bumps up to 2 cm)

When the wall level differences approach 2 cm, gluing drywall should be done in a different way, although surface preparation and gypsum board, primer, laying of the electric cable do not differ from the previous version.

The instructions for gluing GCR to moderately uneven walls are as follows:

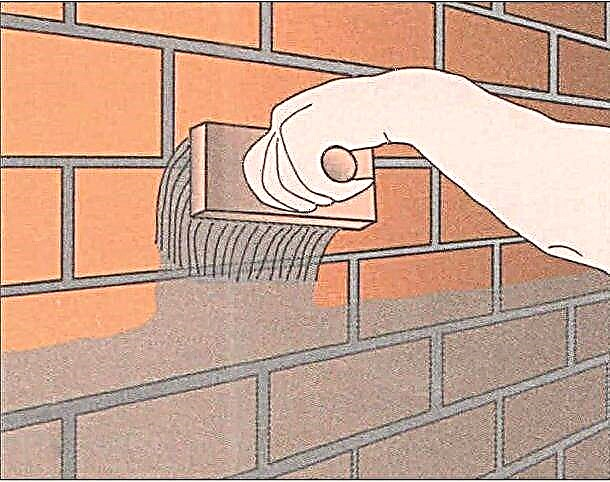

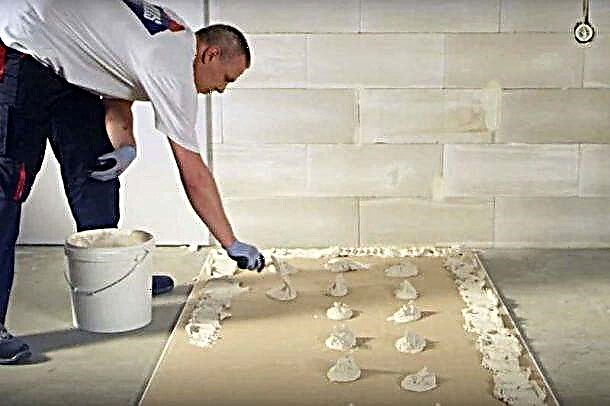

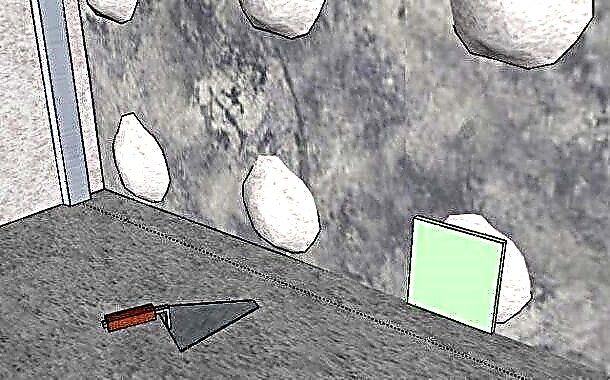

- The adhesive mixture is prepared in a larger amount than in the first case, it is applied to drywall not with a notched trowel, but with separate dots or even heaps, as in the following photo - this will smooth out irregularities and, as a result, provide a firm fixation of GCR on the wall.

- The sheet is placed on the lining at the place of attachment - the beginning, as a rule, is the most protruding section of the wall surface.

Glue points are made around the perimeter of the sheet at a distance of 25 cm from each other, inside the perimeter they are placed every 40 cm. There should not be large gaps, so that the fastening does not suffer. For the same reason, you need to ensure that the height of the points is greater than the wall level differences.

- Bonding begins with the output of the electrical wires and a light clip of drywall, which should simply cling to the wall. It is better to work together, so that one master constantly holds and, if necessary, helps to press the sheet.

- The final fastening is preceded by a thorough check of the plane in all directions to determine in which places to press the material. If flaws are identified, individual sections are knocked out, the process continues until complete satisfaction with the result.

A special option is when drywall is attached to the surface of gas or foam concrete. In this case, for reliable fixation, the adhesive composition is applied not to the sheet, but to the wall, although this method requires carefulness - when installing GCR, it can be easily skewed.

Option number 3 (differences more than 2 cm)

Technology for surfaces with large irregularities:

- Unstable plaster sections are removed from the ceiling.

- Thoroughly primed walls.

- Beacons are being prepared: strips of 100 mm width are cut out of drywall to create an even foundation. These elements are placed around the perimeter of the wall and vertically through 40-60 cm. They are fixed with glue, the layer of which is adjusted for level fluctuations.

- The main sheets of drywall are glued to the beacons after the final hardening of the adhesive on the strips. They are attached using the composition that was used to create the lighthouses. The adhesive mass is applied in lines along the width of the guides, after which the sheet is lifted and pressed against the beacons. If they are aligned correctly, installation is not difficult.

- Joints of paintings are treated with glue or special putty.

- After drying, the primer is primed again, given time to dry, and finally plasterboard the surface of the drywall.

The GKL sticker, like any business, is feasible for those who love and know how to work. Such people will benefit from today's publication. For those who are determined to do all the work from start to finish with their own hands, a video with a visual description of the process will help. Ask questions in the comments to the article. Good luck in your creative endeavors!

And you can see everyone

- What adhesives have sufficient adhesion to the surface of gypsum plasterboard? On what to stick drywall to the wall or finish to drywall?

All adhesives can be used without exception: the porous surface of kraft paper (it is also construction cardboard, the outer layer of gypsum board) provides reliable adhesion to the vast majority of binders.

The drywall surface has excellent adhesion to any binders.

Here is a list of those adhesives that can be used to join drywall with other surfaces:

- Gypsum specialized adhesives (Perlfix from Knauf, Russian Volma Montage and others like them),

Perlfix plaster glue from the German company Knauf.

- Gypsum plasters, starting and finishing putties. Their price differs little from the cost of gypsum glue. Adhesive qualities and shrinkage during setting are also at about the same level (in any case, I did not notice any difference when using both),

- Specialized polyurethane mounting adhesive in an aerosol can,

- Successfully replacing its mounting foam. Preferably with a minimum coefficient of expansion during setting.

- All tile adhesives,

Cement tile adhesive is also suitable for our purposes.

Benefits

Knauf adhesive mixture for gypsum plasterboard became the leader among analogues for several reasons:

- Made on a gypsum basis, it is ideal for installation of gypsum plasterboard. At the same time, due to its good adhesive ability, it reliably holds heavy sheets.

- You can use glue for GCR "Perlfix" at temperatures from 5 to 30 degrees Celsius.

- The most durable fixation of the base plate is already achieved with a 2 cm layer of composition.

- The mixture in the frozen state is moisture resistant, therefore, the frameless method of attaching GCR can be used in damp rooms, such as a bathtub, balcony or kitchen.

- Perlfix adhesive mixture is not harmful to health, as it does not contain biologically

active substances. - Properly prepared, it allows you to make correction of the GCR sheet on the basis for another 5 to 10 minutes, while the glued drywall does not “float”.

- Ease of preparation and use.

On practice

However, the specifications declared by the manufacturer in fact do not always correspond to reality.

- In order for the installation result to be as it should, the master must be quick, it is necessary to make all measurements and trimming, to prepare all the materials and tools in advance, since the composition hardens very quickly.

- The solution prepared in the required proportions after 30 minutes will already be unsuitable for application.

- It is also noted that in the process of complete drying (the manufacturer takes 5 to 7 days to do this), a slight movement of the gypsum board sheets is observed, therefore it is better to postpone the finish, like puttying.

- Estimated consumption of glue for Knauf drywall, declared by the manufacturer - 5 kg per 1 square. However, this calculation does not coincide with the real one, since in practice each specific installation case requires its own approach.

Acquisition and storage

When deciding which glue to choose for drywall, the first thing to do is look at the date of its manufacture, and also pay attention to storage conditions. For Perlfix glue of the Knauf trademark, the maximum allowable period during which the material retains its technical characteristics and qualities is 6 months. This is provided that the original packaging is not damaged, the storage room is dry and equipped with pallets and ventilation.

At home, after opening the packaging, unused material can become unusable even faster. To prolong the life of the dry solution, it is necessary to close the packaging as tightly as possible, store in a dry and ventilated room.

Terms of Use

The initial purpose of Perlfix is gluing drywall during installation in a frameless manner. It is possible to glue to the most various bases. The only condition for reliable GCR fixing is the absence of dust on the surface on which the sheets are mounted. Accordingly, the base must be strong, solid, without flaking defects.

Before proceeding with installation, any surface should be cleaned and primed. This procedure will help hold together the base particles and increase the adhesion of the adhesive.

In addition to installing gypsum plasterboard, Perlfix can be used for gluing gypsum panels, installing insulation (mineral wool, polystyrene foam) in rooms where there is no direct contact of the solution with water.

Procedure for mounting drywall on glue

The frameless method of attaching GCR is very simple. Any person can easily cope with it, even without the experience of such work. The main stages of working with Perlfix-adhesive for drywall:

- We lay wiring as necessary and prepare a place for sockets and switches.

- We clean the surface. We remove all unnecessary and grounded.

- Using a plumb line, building level and rules, we determine the curvature of the walls. Based on the results, it will be possible to determine how to glue drywall, how much solution will need to be prepared.

- We prepare the GCR of the right size, if necessary, cut out the required number of pads.

- Drywall adhesive is mixed in the same way as putty. A small amount of water (2 to 3 liters) is poured into a container (for example, a plastic bucket). The dry mixture is gradually poured and mixed with a mixer. Add the dry mixture to the water to a thick state. The approximate proportion is indicated on the packaging by the manufacturer (15 liters per 30 kg of mixture).

- If necessary, align the surface should arrange the lining of the pieces

drywall, adjusting the level and plane using the rule and level. When the solution sets, you can proceed with the installation of sheets on the glue. - The standard for applying Perlfix to the wrong side of a gypsum plaster sheet is dotted with flat cakes along the contour of the sheet with an interval of 5-8 cm and less often a few pieces in a checkerboard pattern in the central part of the gypsum plaster. If the wall is as straight as possible and alignment is not required, you can apply the solution in a continuous layer with a comb spatula (for tiles).

- We put the sheet in its place and press. Drywall is also aligned according to the rule. All work should be done very quickly so that it is possible to correct the sheets (tapping should be done only through a wooden lining, so as not to damage the drywall). It is important that there are no voids in the joints between the GCR. It is necessary to distribute the mixture as evenly as possible, because it essentially plays the role of a frame for drywall.

- We close the room without drafts and at minimum humidity for seven days. Only after this time can you start finishing.

Other means for frameless installation of drywall

GKL can be glued to the walls not only with Perlfix. In the assortment of building materials of other companies there are dry mixes for the installation of drywall. For example:

- TM "Master" produces a mounting mixture for drywall, packed in bags of 30 kg. The working time for this mixture is 60 minutes, correction is possible within 15 minutes. The proportion is 0.4 liters of water per 1 kg of dry mix. Material consumption - from 5 kg per 1 square. m

- Glue for GKL Siltek T-88 is a material of high strength. Its approximate consumption is 6 kg per 1 sq. Km. m. Proportion - 8 liters of water per 30 kg of dry mix. The correction time is approximately 10 minutes. Shelf life is 12 months. This glue is much cheaper than Perlfix.

- The Volma trademark offers gypsum mounting adhesive, similar in characteristics to the GKL adhesive from Knauf. A distinctive feature of this glue is a shorter period of complete drying. The manufacturer claims that this plaster mounting adhesive fully sets in a day. Also, the average consumption is much lower - only 2 - 3 kg per 1 sq. Km. m

According to experts, in order to glue drywall, you can use the usual starting gypsum putty. However, the adhesion quality and durability of such an installation can be significantly less.

Drywall installation: instruction

First you need to prepare the walls. They need to be cleaned of plaster, putty, paint and whitewash. When the walls become clean, cover them with a primer.

Advice! Primer twice without interruption for drying the wall.

How to make gypsum glue:

- Pour clean water at room temperature into a wide container.

- Pour the dry mixture into the water, evenly distributing it.

- With a construction mixer, mix the mixture until smooth.You can use a spatula, that is, knead the glue manually.

Apply glue to drywall in separate cakes with a step of 25 cm. Now the sheet is applied to the surface and leveled (first you need to mark the wall). The sheet is pressed against the wall to spread the glue. If the drywall is attached to the foam, then its layer should be as thin as possible, since when it sets, it expands.

Recommendations

Pay attention to several recommendations that will simplify the installation of drywall:

- With significant irregularities, the use of glue is impractical due to its high consumption. It is better to carry out the installation of GCR on a frame basis.

- Foam is better to choose with a minimum coefficient of expansion.

- GKL can be glued to the ceiling. Use thin and light sheets, as well as special stops that will support the sheet until it is fully adhered.

- The temperature of the walls during the installation of GCR should not be lower than +5 degrees, otherwise instead of setting the glue, water will crystallize in it.

- Due to the thickness of the glue, the problem of uneven walls can be solved. Only for this you need more solution.

- You can apply glue on a drywall sheet in several wide strips.

Whatever installation method you choose, always give preference to an expensive but proven adhesive manufacturer. It is better to pay more, but to be sure that the drywall is glued for centuries, than to constantly be afraid of the deformation of the sheets.