3 fixing joints of drywall sheets is a responsible procedure, since improperly sealed joints between gypsum plasterboard will lead to the appearance of cracks on them, which can spoil the entire appearance of the finish, especially if you have → drywall painted (here you can find out about gypsum plaster painting without puttying).

When cracks between GKL sheets are dangerous

Cracks between the sheets of drywall are dangerous only in one case - when the drywall is painted, without wallpaper. Then these cracks will be visible, and spoil the appearance of the finish.

Plasterboard wall crack

If the wall was prepared for gluing the wallpaper, then the cracks in the seams of the drywall are not terrible, because they are not visible under the wallpaper, and the wallpaper will not tear - this is not the tension (unless, of course, the gypsum board is not mounted somehow and even hangs a little).

Let's get to the bottom line.

Preparation of seams for sealing (flashing, primer)

If the seams are with the factory edges of the sheets, then it is not necessary to embroider them; they are already ready.

Factory (left) and trim joints of drywall

If the edges of the sheets are cut, you need to make a chamfer (edge) on them. It is carried out either before the installation of drywall with a special plane according to the gypsum plasterboard, or after installation with an ordinary construction (clerical) knife with replaceable blades 18 mm wide.

With a knife, carefully cut the chamfer from the edges of the gypsum plaster at an angle of 45 degrees

Gently with a knife we cut the chamfer from 2 edges of the sheet “at an angle of 22.5 degrees to a depth of 2/3 of the sheet” - as it is written in a technologist from Knauf, the angle in total is 45 degrees. You can cut at an angle of about 45 degrees (preferably not more) to a depth of half a sheet. Having sewed all the seams so that they are primed with deep impregnation soil, both the seam inside and at a distance of 5 cm from the edges along it, it is convenient to do this with a wide brush or brush-brush. Leave to dry. This is not the only way to stitch seams, there are several more, let's see.

Forming a wide bevel according to the type of factory

To form not just a V-shaped recess, but to make a practically factory seam is not an easy task. Cool masters do that. What for? Because when a factory joint is sealed with tape and putty, a tubercle does not form. And when the cut joint is sealed, this tubercle is formed, since there is no depression under the reinforcing tape. This hillock somewhat complicates further work. When puttying, you have to apply a thicker layer of putty to hide this mound, display the entire plane under this ... mound. Also → painting of drywall without putty with such bumpy joints is almost impossible, because this hillock will stick out, will be noticeable.

And here - whoever is much, someone just cuts the chamfer with a knife.

Chamfering with a recess with a simple knife

Someone approaches the process more seriously and technologically, creating for the grinders special nozzles for GKL milling, this is shown in the video.

At home, of course, such methods are useless, and if the wall of gypsum plaster is putty in 2 layers, then all the bumps will disappear under the putty. In extreme cases, you can cut a chamfer with a knife, but it does not look neat.

To avoid cut joints, you can order gypsum board with a ceiling height, so you will not need to trim it in height and the joints will remain as factory as possible.

Preparation of joints in / at the corners

Seams at the corners, at the joints of sheets or with the wall require a little special treatment. So, if you have 2 sheets joined in the inner corner, you only need to remove the chamfer from one sheet that is adjacent to the second.

Cut the chamfer from one sheet that is adjacent to the second

The same applies to the joint, when the sheet adjoins the wall (not from GKL), it is also only necessary to embroider the sheet, with the wall, of course, nothing is needed, then when we close the joint everything will be clear.

It is better to draw external corners with paper tape (see below) and mount corners on top of it - metal or plastic for plaster or putty. Plastic corners are those that immediately with a net-serpyanka - they are also good.

The design of the outer corner at the joints of the GCR

That's the best way to draw an external corner at the joints of sheets of drywall, BUT, under a metal corner, it is best to glue a paper tape for GKL joints at an angle if the surface is supposed to be painted, if it is under a wallpaper, you can. It is better to attach metal corners to putty / plaster, first smearing it with a corner, and then fixing the corner. In the photo they are screwed on with self-tapping screws, which slightly spoils the corner, it can be twisted, which will affect the quality of the finish.

We close cavities and holes from self-tapping screws

Deepenings and places of GKL fastening with self-tapping screws also need to be repaired with the same putty for joints. First, it is necessary to check whether the self-tapping screws are not protruding from the plane, if necessary, tighten them so that they are recessed into the sheet by 1-3 mm.

Perfectly recessed self-tapping screw

Putty these places flush with the surface.

How to reinforce the seams: mesh-sickle or paper tape?

This is not an easy question. Most just close the seams with a speck and putty. But the serpentine net does not reinforce the seam enough, and it cracks over time. Such a crack, as I said in the first paragraph, is not particularly scary in the case when the crack itself is covered with wallpaper. If the GKL wall is painted, then such a crack will be visible.

What to do? Close up, the seams between the sheets of drywall is best paper tape for joints.

Paper tape for GKL joints

The paper tape is much more reliable in closing joints between sheets of drywall, cracks almost never form with it, because the paper itself does not tear, since it is additionally reinforced with fiberglass. More precisely, it can break, but such an effort is not created at the seams of the GCR. Let's take a closer look at this option.

Do-it-yourself reinforcement and sealing of drywall joints with paper tape

We have embroidered the seams, primed them, the primer has dried. It is better to close the seams with special putty for GKL joints, for example Fugenfuller (FUGEN) from Knauf. You can use ordinary stucco, mixed on a deep penetration primer, this method can also be suitable if you plan → to putty drywall, since the stucco has a large fraction.

Knead the solution according to the instructions. You don’t need much, it’s better to knead again.

Close the seam

First of all, we close the seam between the sheets of drywall, for this we need spatulas: one is wide, it’s more convenient to use a trowel, the second one is narrower - 15-20 cm and 5-7 cm, so that it goes into the factory joint less, and the bigger one - on the contrary - was wider than the factory joints .

Spatulas: 5-7 cm and 15-20 cm

Completely (!) Fill the seam from the inside with putty, squeezing it a little inside the seam so that the putty fills the entire space in the seam.

If there are many seams, you can make a simple adapt from a bag of milk or a pastry bag (there are many options).

Like in the photo, the bag or bag should be durable. In this way, it is convenient to fill the joints of drywall with a solution. This is a small life hack, let's continue.

We fill the seams and the space around them at the edges a little more than the width of the tape.

We fill the seam itself and the space around the seam to the width of the tape

Glue tape

Next, we unwind the tape from the roll to the seam length, cut it off (tear off). We glue the seam with tape exactly in the center and press it with a spatula, gluing the tape to the seam, squeezing the putty out from under the tape so that there are no voids with air. Glue the rough (pimpled, inner) side of the tape to the gypsum board. We do one seam at a time.

Glue the masking tape on the joints of the gypsum plasterboard

With a small spatula we pass along the entire length of the joint / tape, slightly pressing the tape into the seam. Further, when the tape is glued, with a wide trowel we putty on the joint flush with the surface.

The tape should be inside the putty layer.

It will not be possible to putty flush at the cut joints, a hill will form there, which will disappear only when → plasterboard is putty (the link tells how to putty drywall).

We close the seams in / at the corners

Everything is about the same, only the tape is glued to the corner, it has a special fold in the middle, thanks to which it is convenient to close up the corners.

After the glue has dried, the outer corner is formed met. corner, as described above. Or plastic, you can with a serpian net. Putty is enough for the inner corner, carefully removing the angle with a spatula.

Close up the inner corner with the same tape and putty

Grind, grease

After drying the seam, usually the next day, it is usually required to putty the seam again, since the putty has the property of being drawn in, shrunk.

Further, when all our layers have dried, we grind the puttied surfaces with sandpaper with fine grain or an abrasive mesh (40-60). If necessary, putty in the right places.

How and what to repair cut drywall joints

As already mentioned, closing up the cut edges of the drywall with a tape in this place forms a tubercle. You can close such joints with strips of fiberglass, which is much thinner and which does not swell from getting wet. One of the drawbacks of paper tape is that it can swell when wet, but when laid inside a seam, it does not swell, which cannot be said for cut seams. Therefore, it is more advisable to use fiberglass strips on cut seams.

Seams with cut edges of gypsum plaster should be repaired with fiberglass

That's all, our joints are ready for further decoration and do not crack! Ideally, drywall after sealing joints can be glued with fiberglass over the entire area, so nothing will crack, and, moreover, the surface will turn out to be homogeneous, which is good for painting. But the above method is quite enough for high-quality sealing joints GCR.

Leave your tips and comments below. Subscribe to the newsletter. Good luck to you, and good to your family!

The need for joint repair

Even the best master will not be able to connect two GKL sheets between themselves without forming a joint. The size of the seams will depend on the type of sheets, the presence of edges, the quality of the fasteners.

The edges of the material can create highly visible recesses or protrusions on the wall, partition or ceiling. You can fix the problem only if the finish is done correctly. Rough seams are formed if not enough profiles have been used, the frame will not be rigid, because under the weight of the sheets the structures are deformed and sag.

Sealing joints carries both a decorative and a functional role. If you do not gloss over them, such troubles arise:

- the base will be uneven, it will look ugly,

- GCR can deteriorate from direct effects on the edges of temperature, humidity, sunlight,

- the finish (paint, wallpaper, putty) will become detached from the base, crack - it will not work to hold it securely.

Paper tape

Paper tape is sold in rolls of 50 - 150 meters, the width is usually about 50 millimeters. Paper tape is stronger than regular paper because it is reinforced with fiberglass in different directions. The surface of the strip is not smooth, but rough, which is necessary for reliable adhesion with plaster, gypsum putty or other finishing materials.

In the center of the tape there is an insert that facilitates the work with the material. The tape can be glued not only between the sheets - it is possible to reinforce the corners of the structure of gypsum plaster. Unlike ordinary paper tape, the tape layer does not wrinkle, does not stretch.

The disadvantages of the finishing method include the complexity of installation compared to a simple sickle. If the putty was made in violation of the technology, air will get under the paper tape - sooner or later the material will peel off. But such a minus is deprived of perforated tape, putty for which does not have such an important role.

Self-adhesive Serpyanka

Typically, experienced finishers when repairing the ceiling, walls for sealing joints on the gypsum board use a sickle. The material is sold in rolls of 20 - 90 meters, can have different widths - up to 5 cm or more.

The most convenient mesh is self-adhesive; it is convenient to attach it to sheets of drywall with any edge. Serpyanka can close up cracks, chips, holes, for example, under the wallpaper. There is also a regular, non-adhesive mesh on sale, which is much more difficult to attach, but it costs an order of magnitude cheaper.

It is better to buy a small roll of self-adhesive material, because after opening it cannot be stored for a long time due to loss of properties.

Putty

Puttying is an excellent method to rub the seams between sheets of gypsum plaster. Puttying joints is recommended if the room is being prepared for painting or for pasting with thin paper wallpaper.

Putty mixture must have excellent quality, otherwise it will crack with time. It is necessary to pay attention to the ability of the product to withstand shrinkage.

Plaster-based putties and grouts - a suitable option for drywall, give a smooth, durable surface with a perfectly white color. It is better to putty with a proven means of a reliable brand, for example, Knauf (Knauf).

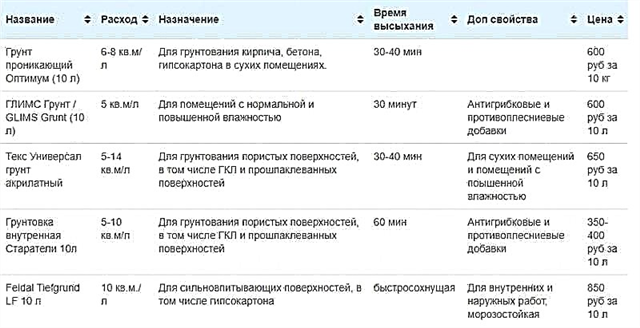

Primer

The priming of seams that have already been coated is an obligatory step in the process of sealing them. The primer will act as a bonding component, complete the draft repair of the ceiling or walls before finishing.

Which is better to choose a primer? It is worth buying an agent with antiseptic and fungicidal additives that protects the surface from the appearance of fungus, mold. After coating with GKL primer, it will not be afraid of moisture, especially if you apply the solution on 2 - 3 layers.

Plaster

The stucco mixture is used as a topcoat to create a beautiful, even surface instead of a prominent joint. Coating the base with plaster is recommended to enhance the adhesion of the GKL sheets with subsequent coatings.

Necessary tools

For work, you should buy the basic materials with which the seam will be sealed - a dry grout mixture (putty), a finishing agent for creating a perfectly smooth surface, a primer (preferably deep penetration acrylic). If the room is prone to cracking (for example, a new house), the most appropriate option is to purchase an additional sickle reinforcing the paper tape.

To close joints at complex angles, you can not cut pieces from a sickle, but buy finished perforated corners from the same material.

Of the additional devices for repair you will need:

- soil roller or brush,

- different size spatulas for puttying,

- Falcon - a plate with handles, which the wall will be puttied on (perfectly evens long sections), can be replaced with a wide spatula,

- a construction mixer or drill with a nozzle for mixing the mortar,

- level,

- sandpaper attached to the bar,

- painting or clerical knife,

- container for diluting the dry mixture,

- personal protective equipment - gloves, respirator, protective clothing, glasses.

Sealing procedure

In order to correctly carry out the whole range of works, it is necessary to comply with the conditions indicated by the manufacturer on the package (regarding humidity, room temperature). There should not be a draft in the room, it is better to ventilate the room after the putty material has dried.

First you need to check the GCR for the reliability of the connection with the profile. If the sheet is held weakly, this will lead to the rapid destruction of the sealed seam, and even a sickle will not interfere.

Preparation for work

The choice of type of building material depends on the subsequent decoration of the walls or ceiling. If you plan to stick wallpaper, the dry mixture can be coarser, inexpensive, especially when the canvas is thick, embossed. Even cracks that appear do not spoil the appearance of the finish, because under the wallpaper flaws are invisible.

What material to apply for painting? The quality of the putty should be higher, because even minimal defects cannot be hidden under the paint. You should not buy cheap mixtures, it is better to take a good snow-white finishing putty.

As for the sickle, there are a number of recommendations for the purchase:

- for brick walls, the width of the tape should be 50 mm,

- for wooden houses, a tape of 100 mm wide is used,

- to strengthen unreliable corners, it is better to take not a sickle, but a metal corner (there are internal and external corners on sale).

For a quality study of the angles, you can prepare a special angular spatula, although this is not necessary. The main thing is that spatulas of 10 and 25 cm are available.

Stitching

Under the alignment understand the processing of the edges (edges) of drywall sheets. Stitching is needed to obtain a surface that will be suitable for further leveling, smoothing. Use a sharpened sharpened paint knife.

- remove scraps, broken areas in the areas of the GKL junction,

- Carefully cut off all protruding parts - chamfers.

Cutting is done by putting the knife at an angle of 45 degrees. As a result, a “tick” should form in the center of the seam. You can even do the alignment before attaching the sheets to the wall or ceiling, as the masters prefer to do. More expensive drywall is already processed in a similar way, that is, it goes on sale in an embroidered form.

Main job

Initially, you need to start a building mixture. It is worth taking a small container, pour water in, add dry powder in portions, mix (it is better to use a construction mixer). If a ready-made thick putty is purchased, a certain amount of it is also transferred to a jar for the convenience of work.

With a medium-sized spatula, take a little mixture, distributing it over the tip of the tool. Smooth the motion of the mass into the seam. Achieve that the solution fully occupied the entire volume of the joint. Then cut the tape or serpentine, impose on the seam along the length, in the center. Squeeze it, then apply another layer of the product in a similar way. As a result, the tape will be immersed in the solution. Once again, grind everything with a spatula, check for evenness according to the building level. Allow the seam to dry completely, treat it with sandpaper.

How to make a seam perfectly even? Professionals apply this technique:

- The solution is applied with a middle spatula, do not smooth, do not remove excess weight immediately after application.

- A wide sharp spatula, set at an angle, is carried out from bottom to top with pressure.

- As a result, putty fills the voids, forming a smooth surface.

It is simply superimposed on the surface only a sickle. The paper reinforcing tape is pre-cut strictly in size, poured with boiling water, and after a few minutes it is wrung out. The surface is puttied in advance, dries, polished. At the end of the work, the partially treated seam is lubricated with PVA, and only then the tape is applied to the desired area. From above, the tape is again treated with PVA glue. The final seam is finishing putty.

There are a number of useful tips that you should follow when closing seams yourself:

- When applying a sickle on a self-adhesive basis, you can not tear it off immediately. The material is distributed gradually, tightly pressing to the seam.

- When working with a sickle, it is important to close all fasteners.

- Gypsum putty is ideal for grouting, which allows the walls to breathe.

- You should not dilute immediately more than 3 - 5 liters of the mixture, because the composition dries quickly and can harden directly in the bank ahead of time.

- Oil-glue putties for working with gypsum plaster are not recommended, they give a lot of shrinkage.

- Do not use dirty dishes, tools to dilute the mixture - this will reduce the quality of work.

Do I need to prime drywall before puttying?

Primer - a special quick-drying solution that improves adhesion between materials, reduces the consumption of putty, and prevents dehydration of adhesives and paints. In addition, it additionally protects the sheet from damaging factors - humidity and aggressive effects of the components of adhesive compositions.

If the drywall is not primed before the putty, the leveling mixture will lie poorly and loosely adhere to the paper base, and the structure will be loose and fragile. It can be quickly peeled off along with wallpaper or paint, which will lead to the need for expensive repairs.

Manufacturers produce special primers for acrylic-based drywall. They are environmentally friendly, give waterproofing, resistance to mold and fungi, fire resistance, without reducing vapor permeability.

Before you putty drywall, you need to choose a primer based on operating conditions:

- For wet rooms, moisture-resistant compounds are preferred, which form a water-repellent film on the surface of the drywall.

- For heavy wallpaper, decorative plaster and tiles, deep penetration agents are designed. They additionally strengthen the base, increase its bearing capacity.

- For painting or light wallpaper, you can choose a primer with average adhesion and penetration.

Universal primers have been developed for all types of subsequent finishing. The technology provides processing not only the base for putty, but also all layers - starting and finishing.

Priming is carried out with a roller or brush. For maximum effect, the composition should be applied in 2 layers. The room must have a positive temperature. To quickly remove evaporation products from the air, it is necessary to organize good ventilation.

Work sequence

Those people who close up joints and cracks in drywall should know in which order to work. The process is divided into several stages, such as:

- Surface preparation.

- Primer seams.

- Laying putty mixture between joints.

- Then put the first layer of putty on the seam.

- After this, it is necessary to seal the joints with reinforced tape.

- The dried putty layer at the joints is rubbed with sandpaper.

- Then a second layer of putty is applied.

- It should also be rubbed with sandpaper after drying.

Surface preparation

Before starting work on filling seams and joints on the gypsum board, it is necessary to prepare the surface. To do this, clean the coating from dust and dirt. This can be done with a rag or a roller along the surface of the seams.

Surface preparation for putty

Surface preparation for putty

Putty putty in the seam

In the place where the seam or crack between the sheets, immerse the finished putty mixture. Since the layer will turn out quite thick, you need to wait time until it is completely dry. Therefore, putty should be mixed exclusively so that it is enough for laying in seams.

Putty putty in the seam

Putty putty in the seam

The rest of the mixture is better to knead immediately before filling the surface itself, because the solution should be used within 30 minutes after mixing. The video shows the process of laying putty in the seam.

First layer

The surface of the seam is puttyed with a layer of approximately 2-3 millimeters. To do this, you need two spatulas, different in diameter.

- the mixture is collected with a smaller spatula, then it is transferred in an even layer to the spatula with a large diameter,

- then the mixture is transferred by smooth movements to the surface on which the seams are closed.

Plasterboard putty

Plasterboard putty

Grout

When the putty material at the seams has hardened, its surface must be wiped. This will give the plane evenness and aesthetics. To work, you need two types of sandpaper (with small stones and large ones). Large sandpaper is first used to squeeze large protruding sections.

Grouting with sandpaper

Grouting with sandpaper

After that you need to use fine emery paper to comb small irregularities from the coating.

Second layer

The top (finish) layer of putty joints should be done with extreme caution. For a good result, you need to go over the entire surface repeatedly to give the structure a complete look

The grouting process is no different from the first. The main thing is to pass along the surface slowly, so as not to violate the integrity of the coating.

Putty Finish

Putty Finish

Each stage of puttying of joints on a drywall surface must be performed. In fact, there is nothing complicated in the process of creating a smooth, even surface without cracks and seams. The main thing is not to disrupt the sequence of actions and work slowly, for sure. Each owner will be able to cope with the task.

Drywall seams: what determines the stability of the seam

To start studying the question of how to close the joint between drywall, you need to be far away - here you can trace a long chain of interactions, each link of which is responsible for the long-term integrity of the seam. One can say even more - if there is no weak link in this chain, then even when the drywall is wet, a crack does not appear at the joints. Speaking the opposite, then no sealing of drywall joints will help to maintain its integrity if the design of the product itself is made incorrectly - to put it mildly, with violations.

In order for the future joint to maintain its integrity, the following conditions must be observed.

The rigidity of the frame - this moment is provided by many factors. Here you will find the correct placement of the profile, its quantity, reliability, and the method of attaching the frame to the ceiling, and even the quality of connecting the profiles to each other. Let's start in order. Firstly, this is the correct location of the profiles and their number - it all depends on the design. If this is a wall, then it will be quite enough to arrange the profiles with a step of 600 mm, if the ceiling, then here the step is needed less (400 mm). Secondly, no ceiling system, or rather its joints, will be able to maintain its integrity for a long time if the frame is mounted on quick-hangers. Over time, they sag and pull the frame, which, in turn, pulls drywall - as a result, cracks appear. To fasten profiles to the ceiling or walls you need U-shaped brackets or “boots” - this is the name of the people made from the ud profile mounts. Thirdly, the connection of profiles among themselves - the manufacturer did not in vain come up with a lot of all kinds of connectors. Their method of installation and fastening in the frame is clearly designed, and changing them to man-made products is, at a minimum, wrong. If you need a crab cd connector, this means that it is actually required, and no trimming of the profile will replace it - it will weaken the frame, resulting in all the same cracks in the joints.

The presence of a profile at the junction. You can’t do without it - there is no profile to which both edges of drywall are securely screwed, there is no reliably patched joint

There is one very important condition here - the center of the profile should be located exactly in the middle of the joint so that both parts of the drywall are not fastened along the very edge of the sheet. Here we need a clear calculation, with which half of the current masters can not cope - for some reason they believe that this is an unimportant moment.

Chamfer on drywall sheets to be joined

This moment does not concern factory edges - they are perfectly prepared for termination. You can not say about the cut edges of drywall - unshaped joints on the ceiling or walls burst, no matter how you close them well. Therefore, the chamfer is removed on both sheets of drywall - the larger it is, the better (of course, within reason).

If all these conditions are met, then it will be safe to give a one hundred percent guarantee that the joints will not crack. Now, when the backstory of a qualitatively sealed seam has been clarified, we can proceed to their immediate termination.

Joint repair process

A chamfer on the edges of the drywall sheet is done specifically, thereby expanding the joint. So this groove must first be primed. This is done in order to harden the opened layer of gypsum, plus to increase the adhesion of the edge surface.

After drying, the joint is filled with putty to the brim. A serpyanka tape is installed immediately. In fact, a sickle is a reinforcing frame. In appearance, it looks like a medical bandage, but is made of polymer.

To stick a sickle on drywall, it must be laid on a wet filler solution. It is evenly mounted in the middle, closing evenly the edges of two conjugated sheets of gypsum plaster. After which it is necessary to give time so that the putty layer dries well. Next, another layer of putty is applied.

After drying, sanding of the treated areas with sandpaper is carried out. And the last step is the primer. On this we can assume that the plastering of the joints of the drywall is over.

So, in this article we tried to answer several questions: how and how to putty the joints of drywall? This process is not complicated, you yourself could verify this by reading to become and watching the video. We offer a little discussion on this topic. Your comments are very interesting to us.

Andrei

37 years

master of finishing work. Experience 10 years

Preparatory stage

Drywall must be securely and firmly fixed to the crate. Clean the surface of the base from dirt and dust. If there are burrs at the joints, they must be removed with a construction knife.

There should be no protruding elements or other defects on the drywall and seams. The base can be wiped with a regular rag. However, if the GKL structure has stood for some time, then it needs to be cleaned qualitatively.

Many masters neglect this stage, which further leads to a “stumbling" of a spatula about these elements during the application of the solution. Walk your hand through the fastener places. If at some point a self-tapping screw protrudes above the surface, you will definitely notice it. In such cases, the cap must be carefully drowned in the material using a screwdriver or screwdriver.

The factory edges of the sheets do not need to be further processed. However, if your materials have joints of straight end faces or cut parts, then they need to be trimmed a little. At the junction, a chamfer should be made at an angle of 45 degrees. The meter should have a width and depth of 5 mm. Cutting must be done with a construction knife.

Before directly sealing the joints, a primer coat must be applied to the drywall surface. If you bought a concentrate, then it should be diluted with water in certain proportions indicated on the package. If you stocked up with the finished mixture, then you need to mix it well, and then apply it to drywall. At this stage, it should be borne in mind that the processed planes are clearly visible on the sheets, so the whole process must be kept under strict control.

Main works

Now you will learn how to putty the joints of drywall so that the entire product retains an excellent appearance for many years, perhaps if you do everything right, then for decades. First you need to dilute the mixture, but keep in mind that you still need to read for 30 minutes of work, since then it will just freeze and become completely unsuitable for further work. The calculation can be carried out according to this principle, in the case of cement and gypsum putties, you need to use about 1 kg of the mixture per square meter.But in order to seal the joints of drywall more economically, we recommend using mixtures on a glue basis, they can be taken at half a kilogram per square meter.

If you do not know how to properly chamfer drywall, then remember that this is done with a drywall knife, which, at an angle of 45 degrees, cuts off the edge from the edge of the gypsum board. The finished mixture is superimposed on the spatula, you do not need to put a lot of it, otherwise it will just be uncomfortable to work. Now you need to put a spatula along the seam line, maintaining moderate pressure on the tool and making sure that the putty layer covers not only the seam itself, but also a distance of 5-7 cm from its edges. If the putty of drywall joints occurs on a rather long section, then divide it into several parts and process each.

After you finish the overlay of the first layer of putty, it is necessary to proceed with the fastening of the reinforcing tape, which will contribute to a more durable and high-quality setting of the joints. Specialists often call it "sickle". It must be laid along the entire seam to give it greater strength. You need to apply a sickle so that the seam is exactly in the middle of it, that is, the edges of the reinforcing tape should protrude beyond the edges of the seam, and the edge of the drywall should not be visible under the putty layer. Serpyanka needs to be drowned a little in putty so that it is better fixed precisely in the depth of the seam.

The second layer of putty is applied after hardening and fixing the first. With the second layer you are already leveling the surface, making smoother transitions between the seams. In addition to puttying the walls, it is also necessary to putty and self-tapping screws, which can greatly go beyond the height of the drywall sheet, so before you putty the screws, you need to tighten them. You can check the level of their height using the same spatula, for this, guide them along the surface in which there are screws. If he clings, then you still need to tighten. It is necessary to putty the self-tapping screws with the cross method: along, across, so it turns out to mask the self-tapping screws much better.

Specialists who know how to putty the joints of drywall, I advise you to use finishing putty to putty the internal corners, but in this case, you also need to use the corner, which must be attached to the base of the corner, in 1 layer of putty, and then coated with the second. In the event that the drywall seams have a complex, curved shape, then it is worth using plastic corners, which can also be puttied in the same way that no one will notice them.

Putty for drywall - what to choose?

How to putty drywall largely depends on the composition and purpose of the putty. On sale you can find mixtures made on a cement, gypsum or polymer basis. Cement and gypsum are produced in bags in the form of finely ground powder. When cooking, they are diluted with water in the right proportions. Polymer putties are ready-to-use pastes packaged in buckets.

The advantages of cement putties are strength and resistance to water. Most often they are used in humid rooms for work with moisture-resistant drywall. Gypsum putties are plastic, economical in consumption and easy to sand. The scope of their application is only dry rooms.

Compositions based on polymer binders - acrylic or latex - are universal. They are not afraid of water, are well applied, polished without any problems. Fillings differ in the size of filler grains. Mixtures designed to equalize gross errors are called starting mixtures, for final fine processing - finishing. The thickness of the applied layers varies from 0.2 to 5 mm.

Modern high-quality gypsum plaster putties are environmentally friendly, resistant to shrinkage and cracking, and durable. Leading manufacturers are Knauf, Weber-Vetonit, Sheetrock, Ceresit and others.

The third stage is the work on the joints

You can begin to putty joints. If the material is prepared and the primed surface has dried, then there should be no difficulty.

The process is performed according to the following algorithm:

The process is performed according to the following algorithm:

- before the self-adhesive material appeared, it was necessary to first apply the plaster composition and only then recess the reinforcing tape into it. At the moment, everything is much simpler. The tape is simply glued to each joint, right from the roll. You can cut the material with a construction knife or spatula,

- preparing the composition. Pour water into the mixing tank, the norm of which is written on the packaging with the material, pour the dry mixture. With a drill with a nozzle mixer, we begin to knead the solution. The process continues until the mass becomes homogeneous. The solution should be a consistency of thick sour cream,

- we begin to putty the seams in such a way that the composition falls deep into the seam, completely closing it. The right amount of mortar is applied to the large spatula, which is distributed over the surface. The evenness of the joint is achieved by stretching the material on both sides of the seam.

Important! Diluting a large amount of the mixture is not recommended, otherwise you just have to throw away the spoiled material. Example of sealing the ends of drywall As soon as the surface dries, it can take up to 24 hours, it needs to be sanded with a mesh with large grain. If flaws are found on the seams after grinding, then you can close the joints again and grind the surface again after drying

See in the video how to properly seal drywall joints.

Putty consumption per square meter of drywall

- Using gypsum putty is even simpler: one to one when filling walls and ceilings.

- Adhesive-based putty is consumed even less - half a kilogram per square meter is enough.

To calculate the approximate amount of putty, you need to know the surface area of all the walls in the room. It’s easy: each sheet of drywall has a certain size, they are indicated on the label. All the numbers are summed up, and the total area for the finishing putty is obtained.

For the starting putty, the same amount of material is taken, with a small margin

However, in any calculations it is important to adhere to the technology. You need to dilute the mixture in such an amount that it is enough to work for half an hour or less

If you hesitate or get distracted from work, then it is recommended to dispose of the dried putty. Use it is not worth it. It is undesirable to redo the work already done. Either the surface of the wall will not be flat, as expected, or in the long term, finishing materials will begin to fall off the drywall due to the lack of a strong hitch.

Only after completing all the stages of preparing drywall for finishing, you can be sure that it will be firmly fixed. In addition, the trimmed sheets of drywall are easily cleaned from the old wallpaper. Nothing falls off and does not crack. By removing the old canvas, it will be possible to stick new wallpaper. In this case, you do not need to re-putty the walls of drywall.

Types of cracks and seams

The filling procedure is best carried out, taking into account the nuances that can adversely affect the surface of the putty. Features of work:

- Before closing the seams, make sure that there are no drafts in the room. If putty on a draft, then subsequently the coating may crack or become loose on the wall or ceiling,

- cracks after sealing joints appear if the putty was performed at too low a temperature. It should be at least 10 degrees,

- cracks can appear on the surface if the donkey is the foundation of the building. Putty joints crack under pressure

- cracks may occur due to sudden changes in temperature,

- seams and cracks between the sheets of drywall appear due to the fact that the installation of gypsum plaster on the surface is incorrect.

In any case, all these problems can be solved, the main thing is to choose high-quality material, and also to study the sequence of work.

How to repair seams in drywall: materials used

To begin with, we’ll deal with the question of what can’t be used to solve the problem, how can we repair the joints of drywall? Quite often, many masters use not very suitable materials for these purposes, which, it seems, could be used if they were not distinguished by a weak ability to hold on the surface with a thick layer. I will say a little differently - they can be used, but the technology in this case will differ by a fair amount. Apply such materials in thin layers, after allowing them to completely dry. These materials include finishing putty of all stripes.

To seal drywall seams, only two types of materials are used - this is a reinforcing mesh, called seryanka, as well as special glue. Let's talk about these materials in more detail.

- Glue for drywall joints. A striking representative of the materials of this group is a dry building mix called “Fugenfuller” - adhesives like it are adapted so that they do not crack during drying, no matter how fast they dry and no matter how thick they are applied. You can only replace them with glue for installing drywall on the surface - they hold the joint perfectly, but working with them is not very convenient due to their viscosity and high pour point. As an option, some masters use to solve the question of how to putty drywall joints, mixtures for starting putty - in principle, they hold a joint, but subject to the correct manufacture of the frame, the correct strip of sheets of drywall and in general full compliance with all the subtleties and nuances of working with structures from drywall.

- Serpyanka - auxiliary reinforcing tape for drywall joints. It does not help if the frame is weak or improperly made - it is also of little use in case of improper installation. What is a serpentine ribbon? This is a grid made of modern synthetic materials - exactly the same as used for plastering on foam, only it is realized with a narrow tape. Recently, a continuous tape made of special paper has appeared on sale - let's say directly, the option is not very good for one reason. It is simply glued to the joint, on top of which glue is subsequently applied - it does not strengthen the seam and, in principle, does not weaken. In general, there is practically no sense from her.

Drywall seam tape photo

There are practically no options here - you want to make the drywall joint reliable, durable and non-cracking, use a sickle and special glue. How to use them? But we’ll talk about this further.

Corner joints

A large width of 10 cm sickle is used to seal the corners. This will help prevent putty cracking in the future. Alignment of the composition is carried out using an angular spatula for external and internal corners. Directly in the corner, the tape is folded in half for folding. After drying, the grinding is carried out with sandpaper.

Causes of seam bursting

Shrinkage of the house can cause the putty to detach and crack, but this is far from the only cause of the problem.

Other prerequisites for bursting the seam:

- the use of cheap materials, including thin profiles (0.3 - 0.5 mm instead of 0.65 - 0.7 mm),

- fastening profiles with plastic dowels (you need to take metal),

- the formation of a wooden crate from raw timber (the tree bends after drying, cracks appear),

- the formation of condensation, steam between the ceiling and the gypsum plaster, if the room is wet and the drywall is not moisture resistant, or when installing the sheets before the plaster is completely dried, with the windows open,

- installation of GKL butt to butt in a line without displacement of vertical seams,

- violation of the technology of sealing joints, for example, ignoring the use of sickle, priming,

- the presence of a chamfer on the gypsum board without a factory edge (if you forgot to remove it when sealing the seam),

- the presence of a large amount of dust during work.

If cracks appear, you will have to disconnect the entire finish and repeat the repair. It is recommended not to allow deformation and immediately carry out all the steps correctly so as not to know problems in the future.

Why close the seams

Plasterboard sheet joints are a problem area. During installation, difficulties may arise:

- The ends can crumble and break in case of mechanical stress.

- The edges of the sheets at the junction undergo deformation (bend).

- With temperature changes, it changes its width, which leads to the appearance of cracks in the finish, bloating of the edges of the sheet.

- Moisture builds up in the gap which causes spots and peeling of the finish, as well as mold and fungi.

- Inaccuracies in the joint make the surface of the walls and ceilings uneven.

Thus, the lack of proper sealing of the gaps between the sheets of drywall leads to damage to the finish coating, the gradual destruction of the material itself, the deterioration of its appearance. It is important to close joints in a quality manner when preparing the surface for painting.

Drywall joints include several requirements:

- The correct installation of drywall. The primary role is played by the exact location of the profiles and the rigidity of the frame. The joint should be in the middle of the platform of the U-shaped profile (i.e., the edges should rest on a rigid platform), and the crate should have sufficient stability. Otherwise, the edges of the sheet will be deformed, and the seam diverge from vibrations of the coating.

- Reliability of drywall mounting. The seam will diverge due to insufficiently strong fastening of sheets to the frame profiles.

- Alignment accuracy. Any steps at the junction impair the condition and quality of the seam.

- Width. The gap at the junction should not exceed 7-10 mm. A wide seam is more difficult to close.

- The presence of a chamfer. It is necessary to increase the area in the docking area and improve adhesion. Standard sheets with a quality factory bevel. Home-made processing is necessary after cutting drywall.

The specified requirements oblige to carry out the seal reliably and efficiently. Without it, it is impossible to provide an attractive appearance and durability of a drywall construction.

Necessary materials

Drywall seams can be sealed using the following materials:

Drywall seams can be sealed using the following materials:

- Paper tape. It is a reinforcing strip made of high strength paper with fiber additives. A longitudinal groove is made on the tape, which allows for smooth bending when finishing corners. To improve the reliability of the primer, perforated options are available. Known brands of paper reinforcing tapes are Knauf, Sheetrock, NextBuild.

- Serpyanka. This is a self-adhesive tape in the form of a mesh of synthetic threads. Its main advantage is ease of use. Disadvantages - insufficient strength, elongation in tension, tendency to crack. Serpyanka is mainly used for longitudinal seams.

- Putty. Used 2 types of putty - start and finish. The first type is necessary to fill the gap, and the second to align the joint. The most famous is gypsum putty, sold in the form of a dry mixture. In particular, quality material is manufactured by Knauf. Uniflot modifications have polymer additives that make it possible to increase the moisture resistance of joints. Especially for drywall, Knauf Fugen putties are made.

- Primer. Acrylic type deep penetration primer is suitable for drywall. Usually it is a white or colorless liquid that can be smeared with a thin layer with a brush or roller.High-quality primers are produced by Knauf - Tiefengrunt (for preparation for painting, wallpaper sticker), Betokontakt (for tiles). You can use other materials - Ceresit 117, Wagon.

To grout joints in the corners of the room it is recommended to use special materials. Quality is ensured through the use of perforated plastic or metal corners. They are installed with paper tape.

How to seal drywall joints: a workflow

Drywall joints include the steps of:

Drywall joints include the steps of:

- Training. Work begins with a thorough cleaning of the working area from dust and dirt with a brush. The burrs are removed with a knife.

- Stitching. When docking factory sheets, it is not required. From cut it is necessary to chamfer at an angle of 45 degrees. The size of the chamfer (width and depth) is 3-5 mm. It is better to use a planer, but you can remove the chamfer and a knife, taking extreme care.

- Primer. The composition should have a concentration suitable for application. If necessary, the mixture is diluted according to the attached instructions. The primer is applied with a paint brush in a thin layer. The entire seam is carefully smeared, as well as the surface of the sheet at a distance of 12-16 cm from the edge. To speed up the work, you can use the brush-brush or a narrow paint roller.

- Filling the joint with putty. After the primer hardens, a putty mixture is pressed into the gap with a narrow spatula (preferably rubber). We must strive to completely fill the joints.

- Sticker tape or sickle. Reinforcing tape is glued to the filled seam. Perforated or serpianka is pressed into the still-uncoated putty solution. If continuous paper tape is used, a layer of glue is applied over the putty. You can apply PVC. The tape sticks over the seam. The width is chosen so that it overlaps the gap by 3-5 mm. The recommended length of one piece of tape is not more than 3 m.

- Puttying up. After all the layers of hardening are hardened, the working area is aligned with putty. The solution is applied with a wide spatula and carefully leveled.

- Finishing the dry joint with an emery cloth. Finishing is done by sanding with a sandpaper or grinding tool. As a rule, manual grinding using sandpaper in several stages is used. At first, rough sandpaper No. 50-80 is produced. Cleaning is carried out in small sections, the movement is carried out in one direction - from top to bottom. Further, the seal is sanded with fine-grained sandpaper No. 300-400 until the roughness is completely eliminated. The seam should be completely level with the surface of the wall or ceiling. Grinding is done in a neat circular motion, starting from the edge of the plot and moving to the center of the joint.

Seal sealing with reinforcing putty without mesh or tape

Special putties are currently being produced, which allow sealing joints without additional reinforcement, that is, without the use of tape or sickle. Such putty is itself capable of performing a reinforcing function due to reinforcing additives. Among such materials, products under the Semin brand are especially noted.

Special putties are currently being produced, which allow sealing joints without additional reinforcement, that is, without the use of tape or sickle. Such putty is itself capable of performing a reinforcing function due to reinforcing additives. Among such materials, products under the Semin brand are especially noted.

The closing of the drywall joints using reinforcing putty is carried out in the following order:

- Cleaning and stitching the seam.

- Primer. It is superimposed similarly to the described technique, using similar mixtures.

- Putty. It is superimposed similarly to other putty mixtures with a spatula. The overlay is provided in 2 layers, the second layer being applied after the previous one has completely dried. The top layer is carefully leveled.

- Grinding.

This sealing technology requires the choice of good putty. Its features are indicated on the packaging, and in the title there is a link to the fact that it is specifically intended for sealing drywall joints. The main advantage is that tapes and simplification of the finish are not required. The disadvantage is the increased price.

The nuances of grouting corners

When sealing sheet joints in the corners, certain subtleties are taken into account:

- Inside corner. The seam in it is sealed with a paper reinforcing tape or sickle. The technology is very similar to the sealing of joints on the surface. Putty is made with a spatula from 2 sides. Initially, the mortar is applied along the entire length of the seam along one wall. Then, the tool changes direction, and a similar operation is performed along an adjacent wall. A tape is applied to the putty, which is folded in half.

- Outer corner. To finish it, a plastic (PVC) or metal (most often aluminum) corner is used. It has perforation, which allows you to securely fix it with a putty mixture. To increase the strength, the corner can be additionally fixed with self-tapping screws.

When finishing corners, puttying is best done using an angular spatula. Such a tool allows you to provide an even, right angle.

Drywall is widely used in decorating. The problem is the presence of seams between the sheets. Correct sealing gives the surface an attractive appearance and ensures the stability of the finish to operational conditions. You can do it yourself, but for this you need to know how to choose the right material and carry out the work taking into account the recommendations of specialists.