Along with wooden lining, a pvc lining has been used for a long time for outdoor work.

Along with wooden lining, a pvc lining has been used for a long time for outdoor work.

Vinyl and plastic boards are equally in demand for interior and exterior cladding. Due to the practicality of this material and the simplicity of its installation, even a layman can cope with the exterior finish.

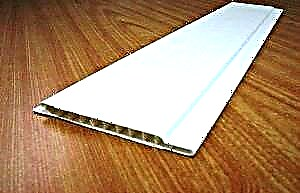

Plastic lining differs from wooden not only in materials, but also in structure. Its internal structure is similar to a honeycomb - a lot of cells welded together. This determines its advantages and features of use.

Material characteristics

Initially, vinyl lining was used in the railway sector for lining cars, which explains its name. Outside, this material looks like an ordinary smooth board with fixing grooves, but thanks to its special “honeycomb” structure, the plastic lining has good heat and sound insulation.

Advantages of vinyl lining

- High resistance to moisture. As you know, wooden finishing materials are exposed to rot when exposed to water. To prevent this from happening, they must be painted with special compounds. Not all manufacturers seek to process their products with varnishes and paints, so this task falls on the shoulders of the buyer, which requires additional costs of money, time and effort. At the same time, a plastic lining for exterior decoration does not need such processing.

- Resistant to insects. As you know, wood is a breeding ground for woodworm beetles. To save a wooden house, it must be painted or treated with special compounds. At the same time, plastic sheathing does not interest insects at all.

Application in a wide temperature range. Depending on the type of wood, wooden materials react differently to temperature changes. Boards may crack, twist and warp from extreme heat or frost. At the same time, the outer plastic finish can be used with equal success with fifty degrees of frost and fifty degrees of heat.

Application in a wide temperature range. Depending on the type of wood, wooden materials react differently to temperature changes. Boards may crack, twist and warp from extreme heat or frost. At the same time, the outer plastic finish can be used with equal success with fifty degrees of frost and fifty degrees of heat.- Resistance to sunshine. This advantage is especially important if you are finishing the house with a clapboard outside. Therefore, it is used to decorate houses, terraces, verandas and balconies.

- Long service life. Plastic materials do not lose their attractiveness over a long period of time. They do not need to be repaired, rubbed, treated and coated with various paints and varnishes. If necessary, pvc panels can be easily painted in the desired shade.

- Incontinence of burning. Houses clad in plastic lining, unlike wooden ones, do not need to be treated with special flame retardants.

- Simplicity of installation work. PVC products are perfectly bent and cut, plastic boards are quickly joined, due to which installation time is significantly reduced.

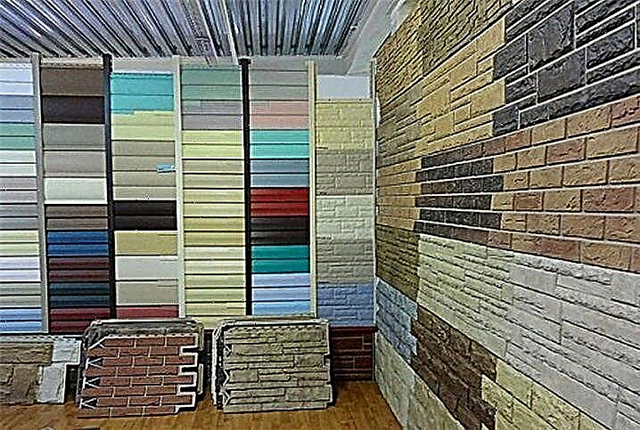

- A wide range of sizes and shades.

- Ease of care. To maintain the pvc finish at the proper level, just wipe it with a cloth or wash with a soft brush.

- Democratic cost of work. Plastic lining is without exaggeration available to all segments of the population.

Disadvantages of pvc lining

Despite the many advantages, this material has its drawbacks.

Due to the low strength of the plastic sheathing, it is impossible to hang anything heavy on the wall of such a house. In addition, the lining installed outside can not withstand a strong blow from the street.

Vinyl does not let air through. Therefore, if you decide to cover the walls of the house with a lining, you need to leave space for air circulation between the PVC boards and the wall so that the insulation does not damp.

Due to the fragility of this material and the high probability of damage to the finish, it is recommended that sheathe clapboard outside only those houses where there is no intensive human flow, since the chances of surface damage increase.

The advantages of vinyl wall paneling for outdoor use

Despite the comparative fragility of the plastic lining, many reasons may influence the decision to cover the building with this material from the outside.

Lining made of polyvinyl chloride has a smooth glossy surface, due to which it does not need to be processed and coated with protective compounds.

Lining made of polyvinyl chloride has a smooth glossy surface, due to which it does not need to be processed and coated with protective compounds.

The lining is available in various colors, including wood paneling, however, if desired, it can be easily painted in the desired color.

Thanks to the presence of special grooves, installation work and finishing the clapboard with any surfaces is carried out easily and quickly.

In addition, plastic is not susceptible to corrosion and decay.

The composition of pvc boards for outdoor use includes a special component that increases its resistance to frost, so when buying material for covering the house outside, check the markings.

Scope of application

Due to its qualities and affordable price, plastic lining is widely used in various fields.

Its most important advantage is that there is no need to process the surface before installation.

Lining hides irregularities and defects of walls. Lining can be used for facades, ceilings, balconies, corridors, verandas and arbors.

Lining is irreplaceable not only in external works, but also in internal rooms where there is a high humidity. It is not difficult to maintain the optimal appearance of the walls sheathed with pvc plates - just wipe them with a wet brush. If desired, the walls and other surfaces can be easily painted in the desired color. After all, the lining is not afraid of moisture.

Vinyl pvc slabs are ideal for decorating a summer house or wooden house.

Lined with clapboard surfaces can withstand severe frosts and sudden changes in temperature, thanks to the special component included in the composition of polyvinyl chloride.

One cannot fail to mention such an important advantage of vinyl plates as flexibility, due to which finishing work can be carried out in the most inconvenient places.

Plastic is a very affordable and inexpensive material. You can buy plastic boards at any hardware store.

Lining - a universal finish, equally well suited for outdoor work and for interior cladding.

Necessary tools and materials

For quick and high-quality installation work, you need such equipment as:

- jigsaw or hacksaw,

- hammer,

- electric drill,

- screwdriver or screwdriver,

- stapler

- water level.

From the materials you will need:

- PVC lining,

- wooden bars for lathing,

- screws and dowels,

- L-profile or baseboard.

Work order

The installation of PVC panels is carried out in several stages:

- First of all, it is necessary to prepare the area on which PVC logs will be installed, remove garbage and clean the surface. If necessary, pieces of exfoliated plaster can be removed.

- Then, in wooden blocks, you need to drill holes for screws at a distance of 50 centimeters from each other. To avoid further unpleasant surprises from insects or high humidity, the bars should be painted or covered with varnish.

- Then the wooden blocks are attached to the walls, for which holes are drilled in them to the size of dowels. According to technology, the distance between the bars should not exceed one meter.

- To avoid bumps, the bars are leveled with a level. Then, along the perimeter of the facade, a L-profile or baseboard is fixed with a stapler.

- The first vinyl board is inserted into the baseboard with one side, and the other is attached to the crate with a stapler. All of the following panels are inserted into the groove of the previous one and are attached to the boards in the same way. If necessary, the panel is cut with a jigsaw or knife.

- If necessary, brackets, corners and profiles are used. Lining does not require additional processing, but if you want to change the exterior, the plates can be painted with the chosen paint.

Description and material properties

The name “lining” in construction appeared by chance - this is how the railroad called a flat and smooth board, which sheathed cars. A puzzle sticks out at the side of the panel, which is held together with an adjacent board.

Thanks to the internal cells, the panels create sound and heat insulation in the room. Lining is made of PVC. The starting material is durable, since polyvinyl chloride does not decay and retains its original appearance for 10 years of operation.

The panels are moisture resistant and tolerate temperature fluctuations from -50 degrees to +50. The plastic lining is also not afraid of the rays of the sun: the material is not flammable. Various color panels are sold in construction stores, so picking up material for a home interior is easy.

The main drawback of building materials is poor strength. Do not place a load on the panel whose mass exceeds 1.5 kg. A strong blow to the lining will leave a rough dent.

The price of the material attracts buyers, so it is used wherever possible when finishing surfaces.

The difference between a plastic lining and a wood or polycarbonate panel

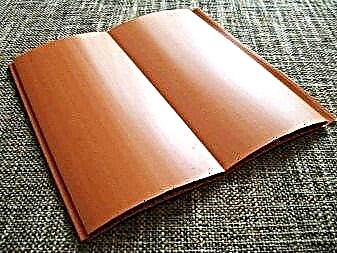

Builders use plastic tiles to decorate the walls inside and out. The appearance of the building material resembles polycarbonate with an admixture of wood. PVC boards are similar to a group of thermoplastics in that both have a porous structure. The ratio of tiles to wood is also easily explained - the appearance is aesthetic and provides a simple installation algorithm.

Lining made of plastic for external finishing works is fixed by means of seams, since the main property of plastic is an increased coefficient of linear expansion. Therefore, the exterior finish is mounted so as not to distort due to temperature changes.

Manufacturers add color pigment to the raw materials of PVC tiles so that the building material initially acquires color and does not paint after manufacture.

Wooden or polycarbonate boards are up to 15 cm wide, which is convenient when designing a seamless joint. The front side of such tiles is covered with paint, which makes it impossible to use building materials for external wall covering. Manufacturers, in the manufacture of polycarbonate plates, add components to the feedstock that make the building material resistant to changing weather conditions and the sun.

Therefore, it is practical to use plastic lining outside, and wooden and polycarbonate panels inside. This does not mean that PVC tiles are unsuitable for creating a design indoors.

Where to use

Plastic tiles have a reasonable price and a wide range of applications. Before assembly work processing of a building product is not required. A smooth board aligns walls and other surfaces. Lining process facades, summer arbors, verandas, corridor rooms and balconies.

During construction, people prefer to clad boards with boards on the outside of the building and the inside, where the humidity level periodically rises. In addition, PVC tiles are easy to clean and wipe with a damp cloth. The building material is repainted if the original color is tired. It’s okay if water gets on the lining.

Finishing from PVC boards looks elite in a summer house or in a wooden house. The vinyl-tiled wall withstands severe frosts and frequent temperature fluctuations. This is due to the stable component, which, in the manufacture, is added to the polyvinyl chloride.

Vinyl boards easily bend and unbend, so it’s easy to design the finish where it is more difficult to do. Plastic is an affordable and cheap material sold in every building supermarket.

Lining - surface finish, which is suitable for installation indoors and outdoors.

Advantages and disadvantages

Let's consider 10 advantages of using facing material.

Plastic is moisture resistant. The wood finish rots if water lingers on the surface. To prevent such a situation, protective agents are released. Manufacturers of wooden panels often miss the coating of building materials with protective equipment: varnish and paint. The procedure falls on the shoulders of the buyer: additional money will be required to purchase moisture-holding varnishes. Therefore, in construction, people are inclined to choose a plastic lining.

The total cost of such installation is lower than other works. The material will be bought even by a person with a minimum wage.

There are no difficulties when cleaning and washing the plastic surface. To maintain cleanliness, the tile is wiped 2-3 times a week with a wet brush or viscose cloth.

The risk of material fire is minimal. A house with PVC cladding does not need to be flame retardant.

Insects will not spoil the finish. Wood is a food source for a thousand insects. To preserve the wooden building, the walls are painted with specific components. Plastic lining does not need such an event, because insects do not feed on plastic.

PVC boards are not afraid of ultraviolet radiation. Such a property is useful for outdoor decoration of the surface of a building. Builders have plastic planks on terraces, houses, verandas and balcony ledges.

Plastic lining will last longer than a wooden or polycarbonate panel. After a year of operation, the plastic board will not lose its appearance and will not lose its color due to exposure to sunlight. It is not necessary to periodically wipe, repair and varnish and paint the material. The color of the panel is easy to change if the previous shade is not enough.

Installation does not take 10 or more hours. The builder will not encounter difficulties in laying out the finish: the plates are easy to bend and cut. The boards are joined together without holes.

Construction stores sell panels of various colors and patterns.

Panels are not afraid of severe weather conditions. Wood reacts ambiguously to sudden changes in ambient temperature. Wooden boards wear out quickly and crack. In addition, at a temperature under +30, the fibers of the tree are gradually twisted. This situation will not happen with a plastic plate: the lining can withstand frosts of -50 and heat of +50 degrees.

Despite many advantages, plastic panels are also characterized by negative qualities. Consider the disadvantages of lining.

Do not place loads of more than 1.5 kg on the boards. The outer skin will crack if an allowance is made. Also, do not hit plastic tiles: the likelihood of a crack is increasing.

Vinyl records do not circulate air. To avoid dampening of thermal insulation, a space for air circulation is left in front of the wall cladding with a plastic lining. Between PVC boards and the wall, builders measure the space for ventilation.

Plastic trim is not durable if installed incorrectly. Builders recommend installing panels in houses where more than 10 people do not accumulate.

Lining is installed outside.

Editing algorithm

To install plastic panels you will not need building skills and additional tools. The following tools are required for installation:

- Hacksaw for wooden products,

- Screwdriver or Phillips screwdriver,

- Electric drill,

- Hammer,

- Construction stapler,

- Water level.

- Before carrying out the work, check the complete set of materials:

- Plastic lining,

- Dowels,

- Wooden bars for lathing,

- Screws

- A profile like a baseboard.

Using the installation of a plastic lining on the ceiling as an example, consider this procedure. First, a place is prepared: garbage is eliminated and extraneous unnecessary objects are removed. After that, inspect the surface on which the panels are fixed. Pieces of plaster are sanded with a spatula if the surface is rough.

Then they prepare wooden blocks: holes are drilled, where self-tapping screws are inserted. The main thing is to place the screws at a distance of half a meter. The tree is pre-treated with paint or drying oil, if the installation is expected in a room with high humidity.

The bars are screwed in compliance with the parallelism of the wall and ceiling. The diameter of the drilled hole coincides with the diameter of the dowels. The distance between the bars does not exceed 1 meter. The accuracy of the installation is regulated by the water level, so the bars are attached in one plane.

The ceiling will be uneven, if you do not mark the place for fixing the bars. After that, a plinth is fixed on the sides of the ceiling with a construction stapler. The initial panel with one side is inserted into the baseboard compartment, the other half is attached to the wooden beams.

The second side is easier - one side is inserted into the groove of the initial one, the other half is attached to the crate. The remaining plastic plates are inserted as well. The panel can be easily cut with a knife or a jigsaw, if necessary during the operation.

How to choose

A person, when choosing a plastic lining, focuses primarily on cost and optimality. First, consider the selection criteria, so as not to stumble on unreasonably expensive goods. We will analyze the key points when buying PVC panels.

Thickness affects the durability of the cladding. Thick vinyl panel withstands loads of more than 1.5 kg. The standard size of this size is 1 cm. In construction stores, boards less than 1 cm are sold, they are needed if the ceiling is covered.

The thickness of the front side affects the ability to restrain mechanical punching and damage. For exterior cladding, it is categorically not recommended to use a plastic lining, in which ribs are not visible through the front side. In addition, when finishing ceilings, such panels do not look aesthetically pleasing.

The distances between the inner ribs do not exceed 1 cm. During transportation, plates with “rare” ribs are deformed or crumpled. Therefore, dents and holes are clearly visible inside the panels. In this case, the front side is not damaged.

The number and stiffness of the vertical ribs also affect the durability of the material. Frequent rigid panel ribs guarantee resistance to mechanical shock and damage.

The shade evenly lies on the area of the PVC panel. Not all manufacturers of plastic lining add color pigment to the feedstock: paint is applied to the front of the board. The buyer soon, after facing, will detect scratches and abrasions on the tile: such a PVC board quickly burns out in the sun.

The weight of the lining depends on the frequency and stiffness of the inner ribs. One plastic panel weighs 1.3 kg.

When purchasing goods, the connecting puzzle is checked: 2-3 lamellas are viewed for fastening strength.

The presence of toxic substances in the plastic lining is undesirable. Some manufacturers add toxic elements to the feedstock. In a hardware store, if desired, the buyer asks the vendor for product certificates. Only the printed packaging with the panels smells specific - this is normal. You can’t buy plastic panels if one, exhibited, has a toxic smell.

The percentage of chalk in the composition of the plastic lining does not exceed 20%. During installation, 2-3 panels are damaged due to the fragility of the lamellas, if the composition exceeds the amount of chalk. Chalk is considered a cheap raw material, so manufacturers often add it to the feedstock in order to save.

Material Specifications

Plastic lining is an artificial material consisting of polyvinyl chloride, plasticizers and chalk in various proportions. It has a cellular structure and is produced by extrusion, i.e. extrusion.

The material is environmentally friendly, the proof of which is the manufacture of disposable tableware, syringes, tension structures and so on. However, this feature does not apply to plastic lining of the lowest price category, characterized by high toxicity and pungent odor.

In general, plastic panels and plastic clapboard are for the same purpose. However, there are a number of differences between these products, primarily the panels are characterized by a larger width of the base of the board. Also, a plastic lining includes a certain coloring pigment, so its color is identical. This feature makes this material more abrasion resistant. Otherwise, there are no special differences between these materials.

Pros of vinyl wall paneling

PVC lining is widely used due to the following operational advantages:

- 100% moisture resistance, which allows the buyer not to spend additional financial resources, time and effort on processing the material with special compounds,

- Resistant to parasites. Unlike wood, plastic sheathing is not a treat for various types of beetles,

- Operation in various temperature conditions. PVC lining feels great both in the conditions of “cracking” frosts and in the southern heat,

- Counteracts ultraviolet light. This feature is truly indispensable for decorating a house from the outside. Therefore, it is not surprising that this cladding is used for the improvement of residential and industrial premises,

- Long service life. Plastic retains its aesthetic characteristics over time. If desired, pvc slabs can be repainted without unnecessary problems,

- Excellent fire protection. The buildings sheathed with plastic lining do not need to be treated with special flame retardants,

- Convenience during installation. PVC products bend perfectly, plastic boards fit together without any problems, which allows to reduce working time,

- A wide selection of dimensions and shades of material,

- Easy to finish. To ensure the originality of the PVC finish, it is wiped with a damp rag,

- Acceptable for the general public, the cost of a plastic lining.

All the above advantages are time-tested and marked by positive comments from a large number of property owners.

Cons PVC lining

The numerous advantages of this material still do not allow us to forget about some of the disadvantages of plastic lining:

- Due to the relative fragility of plastic, it is forbidden to hang massive objects on the supporting structures. Also on the lining of pvc undesirable effects of large mechanical stresses,

- Vinyl prevents air from entering. In this connection, when choosing a pvc lining for wall covering, there is a place for ventilation between pvc boards and the wall, so that the insulation does not lose its properties.

Mindful of the above drawbacks, sheathing with pvc plates should only be done in those buildings in which the probability of surface damage is minimal.

Calculation of the required amount

It is not difficult to determine the required amount of pvc lining for wall cuts. Why focus on the area of the sheathed object. For example, to decorate a room with an area of 12 "squares" of panels for decoration, 140 pieces are needed, plus 40 more such products are needed on the ceiling.

Also, for the installation of pvc panels, the owner acquires 26 and 12 meters of internal corner and floor curb, respectively. During preparation for installation, do not forget about the mounting "bugs" that are purchased in a specialized store. As a result, many owners choose it is the processing of pvc panels, due to the fact that it is exclusively budget.

Mounting technology

To sheathe the facade of pvc buildings with a lining, a person does not have to possess special qualifications and knowledge. To thoroughly carry out these works, we prepare a carpentry tool, as well as purchase fasteners, wooden bars for the lathing, and, of course, pvc lining.

When the sheathed walls of the building are free from defects, the PVC panel can be fastened to them by means of liquid nails. The use of this building material makes it impossible to lay thermal insulation.

The installation of pvc boards itself is carried out in several stages and is carried out in the following order:

- First, the space is prepared, on which pvc logs will be stacked. This requires the removal of debris and cleaning up the area. Also, if necessary, remove the remains of exfoliated building materials,

- Next, in the bars, you will need to make holes for the screws at a distance of half a meter from each other. In order to prevent destruction of the material due to parasites or dampness, the PVC lining is treated with drying oil,

- Subsequently, wooden blocks are attached to the walls, for which holes are made for the diameter of the dowels. According to the rules, the distance between the bars is not more than a meter,

- To prevent unevenness, you must use a level. Next, at the base of the facade, an L-profile or baseboard is installed,

- First, the vinyl board is installed with one edge, and the other is attached to the crate with a stapler. Subsequent products are inserted into the groove of the previous one and are identical to the bars. If necessary, the panels are cut with a hacksaw,

- In some situations, some fasteners are used. PVC lining does not require additional impregnation, but at will change the shade.

Acting in this order, there is no doubt that the quality of the processing of pvc facade lining will be at its best. In addition, this building material successfully competes with metal siding and tiles, due to the excellent price-quality ratio and aesthetic characteristics.

Features

Building a house is a process consisting of a number of mandatory works that are performed in strict order. Finishing the facade of the building is important not only from the point of view of aesthetics, it also insulates the house and protects surfaces from many factors. Exterior wall cladding with plastic lining is in demand among many homeowners, since this material has a lot of advantages.

PVC lining has a number of positive features:

- long service life, due to the fact that the material is not susceptible to decay and corrosion,

- resistance to various temperatures,

- the material is off

- ease of installation

- the appearance of the facade

- surface is maintenance free

- good water repellent properties of the material,

- affordable cost of production,

- products are resistant to negative environmental effects.

But like any other material, plastic products have some disadvantages.

These include the following nuances:

- minimum resistance to mechanical stress and pressure,

- the inability to securely attach decorative elements to the panels.

Unlike wooden lining, before installing PVC panels, there is no need to cover them with special antiseptics and other compounds that prevent rotting of the material, which is a positive thing that saves the homeowner money.

For the first time, lining began to be used for sheathing trains, and on this basis the material acquired its name. In appearance, the product is an ordinary board with an even and smooth texture, on the sides it has grooves that provide connection with subsequent elements.

Plastic lining - this is a panel, inside of which there are individual cells along the rail. The raw material for the production of material is polyvinyl chloride.

The material can be of the following types:

- a panel of the usual form, which visually looks like a bar made of wood,

- calm, the advantage of which is a smooth surface, after its installation, the grooves on the panels are almost invisible,

- block house - a panel with a convex surface that simulates a log,

- “American” - a product with a recess inside the panel, which creates the appearance of overlapping boards.

Paneling visually resembles a wooden beam, this design is the simplest, so most plastic panels for walls are produced with this profile.

Calm, or "Collective Farm Girl", is popular due to the lack of grooves, which are usually visible in other types of panels.

Block house resembles a log cabin, the inside of the panel is flat, grooves for fastening are located on the sides of the product. Products can be used for facade decoration and for indoor indoor use. In addition to the original appearance, such a panel has a good level of ductility due to the presence of special additives in the composition. They provide the product with frost and burn resistance.

Lining "American" It is popular due to the styling features, since the located panels form a good joint protection against the effects of various temperatures and moisture.

Many experts classify plastic lining as follows:

- multi-colored or white panels,

- products made under wood, stone or other materials,

- panels, the main difference of which is the method of their connection - seamless and sutural.

When choosing a facade material, you need to consider that for street decoration it is worth buying a lining for external work. Product differences are only in quality characteristics, visually panels for exterior decoration and products for interior work are not much different.

The front side of the lamellas has two main types - glossy or matte finish. In the assortment of some manufacturers, you can find products that have a semi-matte finish. The external design of products does not affect the quality of the finished product. The most popular color for plastic lining is considered white, in second place - wood products. They purchase color products much less often.

DIY finish technology

In order not to make a mistake in the way of laying plastic lining, first of all, it is necessary to study the technology of installation. There are various ways to fix panels. The most common is the option of vertical and horizontal arrangement of panels, so you can visually increase the walls, due to which the whole building takes on large dimensions. In addition, there is a rather old way - herringbone styling, due to which an interesting pattern is created and there is an opportunity to save material.

Before sheathing the house outside, you need to make a wooden crate for fixing the panels. This design will provide a flat surface for installation. In addition, the frame system allows you to introduce insulation layers into the structure.

The fastening of the elements begins strictly from the corner. The first part of the structure acts as a guide, therefore, its installation should be treated with special responsibility. Having connected several parts, it is necessary to use the level to control the correct and even arrangement of panels on both sides.

The option of lining in length involves laying, where the lining spikes will be located at the top, so that excess moisture will not accumulate in the grooves.

Fastening products can also be carried out by various means, each of them has its own advantages and disadvantages. The easiest way is to use a stapler or nails. However, these elements become unusable very quickly, so they may need to be replaced.

It is best to purchase special kleimers or thin nails. The latter option is not entirely aesthetic, and the use of staples allows mounting on a brick wall or on a surface made of round logs or foam concrete.

When performing work, it is important to maintain a perfectly even installation, especially for independent work.

Tips & Tricks

Plastic lining is an ideal material for cladding buildings with high humidity, for example, baths. When buying materials, it should be noted that the color of the lining from different manufacturers will differ.

When choosing a plastic panel, it is worth taking into account the cost of production, since high-quality products will have a high price.

However, in order not to buy expensive products of poor quality, it is worth considering the main points that will determine the quality of the lining:

- the ability of the material to withstand the load depends on the thickness of the elements. The standard panel thickness is 10 mm,

- the thickness of the front surface of the product must be such that stiffeners are not visible through this side, otherwise the lamella of such quality is not recommended for use as a material for exterior decoration,

- the strength of the product depends on the number of ribs and their stiffness,

- the distance between the ribs should not be more than 10 mm,

- uniform color of the whole product. Many manufacturers do not add coloring pigment to the polymer composition during production, but prefer to process it only with the front side. Such a lining will lose its color very quickly, and possible scratches and defects will be clearly visible on the surface.

When purchasing a lining, it is necessary to familiarize yourself with product certificates, because the panels are made from toxic raw materials. Freshly opened packaging may have an unobtrusive, but specific smell, which is considered the norm. If the smell will be felt from the product, which is in the store as a sample, then the safety of using such products is worth considering.

The weight of the finished product depends on the thickness of the walls of the lamellas and the number of ribs. The standard value is considered in the range of 1.1-1.5 kg / m2. Before you buy the whole batch, it is worth testing the panels for a good fit with each other.

Experts agree that good quality products should not have more than 20% chalk in their composition. Its excess is fraught with a decrease in the strength of raw materials. Chalk refers to materials that have a low cost, so it is often used in production in order to reduce the cost of the finished product.

The permissible content of this component is very easy to check - just bend the corner of the panel for this. If no crack has formed on the bend site, you can use such a material. A white strip or defect indicates an excess of its norm in the total mass.

Products that are produced by well-known brands should be bought without fear, because companies have earned their reputation for more than one year, primarily the quality of the goods, paying special attention to it.

Saving on the purchase of materials for facade cladding is not worth it, as this can result in cost overruns, due to the need for repairs with poor-quality products. A good lining made of plastic will become a decoration at home and for a long enough time will not change its aesthetic and physical properties.

Beautiful examples

Cozy and attractive housing is the dream of every homeowner. The choice of style, taking into account which the house will be decorated, directly depends on the personal preferences of the owner and his desires. Modern high-tech housing or classic Provence can be beautiful and comfortable. For each option, a plastic lining will be a great addition, thanks to which the facade of the building will harmoniously fit into the overall stylistic idea.

Clear and simple lines, contrasting colors of the facade cladding of the building are the main elements of high-tech style. A winning option may be the outer wall cladding with panels of neutral colors, for example, white and black.

A conservative English style will help to set plastic panels for brick, which will advantageously complement the design of the house, emphasizing its respectability and restraint with its practicality and perfect symmetry of the lines.

The English style of decorating the facades of residential buildings is represented by democratic colors, a combination of natural textures or their good imitation with an emphasis on the high cost of decoration. Plastic panels, which are an inexpensive material, completely cope with the task of wall decoration, repeating a painted wooden coating in white or beige colors. Due to the fact that the products can be easily painted with paint in almost any color, the walls of the house can be given the desired shade, corresponding to the overall design. The main thing is to use means suitable for a similar surface for painting.

A fashionable and current trend is the decoration of country houses in the style of a chalet. The facade of this structure, together with the interior decoration, is made of wooden beams. Dear natural material can now be replaced with a high-quality analogue - block house clapboard. The material perfectly imitates a wooden log house, emphasizing the beauty and aesthetics. Frost-resistant plastic products do not fade in the sun and are unpretentious in maintenance.

About the features of plstkovaya lining for outdoor use, see the next video.

Design

Lining from plastic for external works can be of various types.

Below are the most popular designs:

- Lining panel. This product visually resembles a wooden block. Such a system is the most simplified, so most plastic building materials are made with a similar profile.

- Block house. Finishing building material visually similar to a log house. Inside the PVC panel has a flat surface, and on the sides there are grooves for fixing. This type of product can be used not only for external work, but also for internal. In addition to the aesthetic appearance, the product has an excellent indicator of ductility, because in the manufacture, manufacturers add specialized additives that provide building material with frost resistance and resistance to fading.

- American. This option is the most popular type of plastic lining due to the installation features, because the located panels provide excellent protection of the building's facade from high temperature conditions and moisture penetration into the room. Outside, this variation of the lining resembles overlapping boards.

Most experts divide the lining of polyvinyl chloride for outdoor work into the following varieties:

- colored or white products,

- materials imitating wood, stone, as well as with the application of various patterns,

- suture and seamless plastic panels.

How to sew with your own hands?

Before proceeding to cladding a house with a lining, it is necessary to study the methods of laying the finishing building material. The most popular variation is the perpendicular and horizontal placement of products, because in this way you can visually increase the walls. There is also an outdated method of laying panels - herringbone installation, as a result of which an unusual pattern is created, as well as an opportunity to save building materials.

As with other construction work, before proceeding with the cladding of the house with clapboard, it is necessary to prepare the base.

If the sheathing of a wooden building is carried out, then make sure that there are no areas on the surfaces with mold and fungus, because otherwise the surface must be treated with an antiseptic.

Preparatory stage

Regardless of the building material of the exterior walls, they should be thoroughly cleaned of various contaminants. All cracks and cracks are sealed with a special solution. Ideally, the wall should be as aligned as possible.

First of all, the installation of a wooden crate for fixing plastic products - it will create a level surface for installation. In addition, the frame installation makes it possible to install thermal and waterproofing in the system. The frame can be performed independently, using ordinary boards 4-5 thick and 10 cm wide. They are fixed in a vertical position.

Thermal insulation

The layers of mineral wool are mounted. The correct installation of the insulation is carried out in such a way that there are no gaps between the insulation materials. A feature of the laying of layers is that their upper layers should cover the lower plates to the middle.

Due to the natural elasticity of the products, additional fixation does not require heat-insulating material.

Waterproofing

To prevent moisture from entering the room, it is necessary to install a waterproofing layer. For this purpose, you can apply a plastic film. The film is fixed using construction brackets to the bars.

Joints must be glued with tape - this procedure will increase the waterproofing qualities of the structure.

Installation of the second frame

Now you can begin to install the second frame. On the bars of the first frame over the waterproofing film, battens of 2-3 cm thick and 0.5 mm wide are nailed. To prevent rodents and other insects from entering the lower area of the structure, it is necessary to close it with a metal mesh.

Installation of elements starts from the corner. The first part of the installation is managerial, so at this stage you need to be especially careful and attentive. Having mounted several products among themselves, it is necessary to use the construction level.

Variation of the length of the finish implies a structure of materials, where the spikes of the finishing product will be located in the upper part, as a result of which condensation will not form inside the structure.

There are a variety of methods for fixing finishing products. Very popular is the method in which a stapler or nails are used. But such tools can break down in a fairly short time, so in the future you will need to reinstall parts. Experts recommend getting specialized kleimers or thin nails. By means of kleimers it is possible to carry out installation on a brick coating or on walls made of round beams or reinforced concrete.

After completing the sheathing procedure, you can start painting. For some types of paint (for example, oil), a preliminary surface treatment will be required. This is done by applying varnish in two layers. After that, you need to wait until the special coating is completely dry and continue painting.

French provence

This style requires the design of the facade in natural and natural colors.

The following shades are suitable:

Facing the facade of the house, made in bright colors, in perfect harmony with the dark elements: railings, window frames, street wrought iron lamp.

English style

A conservative English look can be created using a brick lining. This design favorably emphasizes the respectability and restraint of the building.

The English style requires the use of simple colors in combination with natural materials or with their excellent imitation. Plastic panels perfectly cope with such tasks. Due to the fact that the products can be painted in any color, it becomes possible to give the walls of the building the necessary shade. The main thing is that the design of the exterior walls is in harmony with the general style of the house.

The most popular variation of the cladding of the building is the image of the chalet. The exterior and interior cladding of the building in this style is made of a wooden bar. Expensive building material can be replaced with a plastic block-lining block house, which perfectly simulates wooden beams, emphasizing the attractiveness and sophistication of the building. Also, the PVC building material has a high frost resistance and does not lose color in the sun, as a result of which such a facade material can be used in the most severe climatic conditions.

For how to sheathe a house with a plastic clapboard, see the next video.

Application in a wide temperature range. Depending on the type of wood, wooden materials react differently to temperature changes. Boards may crack, twist and warp from extreme heat or frost. At the same time, the outer plastic finish can be used with equal success with fifty degrees of frost and fifty degrees of heat.

Application in a wide temperature range. Depending on the type of wood, wooden materials react differently to temperature changes. Boards may crack, twist and warp from extreme heat or frost. At the same time, the outer plastic finish can be used with equal success with fifty degrees of frost and fifty degrees of heat.