For strong bonding of aerated concrete blocks with each other, special glue is used. The basis of its composition is high-quality cement. It is he who is able to provide excellent adhesion qualities of surfaces, as well as high elasticity and strength of masonry. The low consumption of the finished mixture makes it possible to significantly save on construction, having received optimal quality at an affordable cost.

What mixtures are most often used for laying aerated concrete blocks?

Why are adhesive mixtures used for aerated concrete, and not the more common cement counterparts? Aerated concrete has special properties, here the thickness of the joints at the joints should be minimal, which will help to avoid heat loss. Glue for aerated concrete is as close as possible in structure to building material, which cannot be said about the characteristics of cement mortars.

The glue is considered universal, it can equally be used for external and internal works. The seam thickness does not exceed 2-4 mm, which provides a direct economic effect of material consumption and increases the strength of the joints.

For outdoor work in the cold season, it is recommended to use frost-resistant glue, it tolerates any temperature differences and is able to maintain its structure even in severe frosts.

What is adhesive for aerated concrete

A similar adhesive is a dry mortar from which an aqueous solution is made. The proportions of water and mixtures are usually indicated by the manufacturer on the packaging. Aerated concrete glue is used as an alternative to conventional cement mortar for outdoor and indoor construction work.

Application area:

- as a filler used in leveling walls,

- in the construction of walls of aerated concrete and expanded clay blocks, brick, foam concrete, cinder blocks,

- for laying ceramic tiles.

There are two types of glue, which is used in the construction of structures depending on the season.

Glue for aerated concrete can be:

- Grey - It is considered a winter variety, but, in fact, it is universal and suitable for use regardless of the season. The composition includes antifreeze additives, while there are temperature limits for use.

- White - Portland cement is included in the composition, which gives the glue a light shade, thanks to which he received this name. It is considered a summer option and is used in the warm season.

Light color makes it possible to use white glue for aerated concrete blocks indoors and at the same time save on finishing materials.

Composition and advantages

The glue consists of high quality cement, polymer additives, sieved in a special way sand and modifiers. Polymer additives improve the thermal conductivity of the mixture and its adhesive properties. Modifiers provide protection against cracking if the ambient temperature rises.

Benefits:

- the possibility of obtaining joints with a thickness of 2-3 mm, which provides a significant reduction in heat loss through the joints and reduces the cost of construction,

- resistance to low temperatures, with the winter version of the glue, you can perform work in the cold season,

- increased moisture resistance,

- no shrinkage during hardening.

Glue for gas block must be stored exclusively in heated rooms. It is also necessary to make the solution in heat, the water should be hot (+ 60˚ С), the finished composition should have a temperature of at least + 10˚ С. In the cold season, the prepared solution should be used up as soon as possible, since after 30 minutes it will lose its qualities.

Selection options

Aerated concrete has special properties that do not allow to obtain high-quality masonry using ordinary cement mortar. This is because the seams will be thick and cause serious heat loss. The glue for aerated concrete blocks in physical properties is very close to the parameters of the building material, so it fits perfectly. An ordinary cement mortar does not have such characteristics.

When erecting buildings in the northern regions, it is advisable to use gray glue. Its characteristics do not deteriorate at a temperature of + 5˚C - the composition does not spread and has excellent adhesion. Temperature limits of application are in the range up to –10˚ С.

Advice! The adhesive composition used during construction in winter should always have a temperature above 0 ° C. This will ensure adhesion and insure against damage during operation.

Professionals recommend not saving when buying glue for aerated concrete, choose only brands with an excellent reputation, time-tested, which consumers respond well to.

Which glue is better can be decided by testing. Buy several different adhesive compositions and try each of them to glue 2 aerated concrete blocks. After 24 hours, break the joint and carefully examine the junction. The best option is when the block breaks, and the integrity of the seam is preserved, it is this glue that must be acquired.

If the joint is split along the seam - poor quality glue, do not buy it. In the case when both the gas block and the seam partially broke, the adhesive mixture is not very good.

Manufacturers

Professionals recommend several companies that produce glue, which managed to prove themselves on the positive side in the construction market.

Most popular brands with excellent reputation:

- Bonolit (Bonolit) - Products appeared on the market relatively recently. The adhesive contains components with modifying and antifreeze properties,

- "Moment" characterized by high adhesive properties with respect to building material,

- “Warmit” - masonry mix from a Russian manufacturer, the composition includes ash, which provides an increase in the strength of the seam, but consumer reviews on the product on the forums are not always positive,

- Volma - glue is characterized by increased resistance to low temperatures, you can work with it at temperatures up to -15˚ С,

- Kreisel 125 suitable not only for gas silicate and foam concrete blocks, but also for porous concrete, polystyrene concrete blocks,

- Kreps used for masonry inside and out, at + 20˚ С the adhesive retains its properties for four hours,

- "Real" - it is possible to work with masonry mix at a temperature from +5 to + 30˚ С, it is applied for external and internal works,

- Ytong - polyurethane adhesive, characterized by increased strength, the ability to retain water and excellent adhesive properties, produces a summer and winter variety, under this brand foam adhesive is produced,

- AEROS designed for indoor and outdoor use; white and gray masonry mixes are produced,

- Ceresit ct21 Great for indoor and outdoor building work, puttying indoors.

Advice! The use of fine-grained glue, which ensures uniform masonry, will allow avoiding cold bridges when working with aerated concrete blocks.

How to put

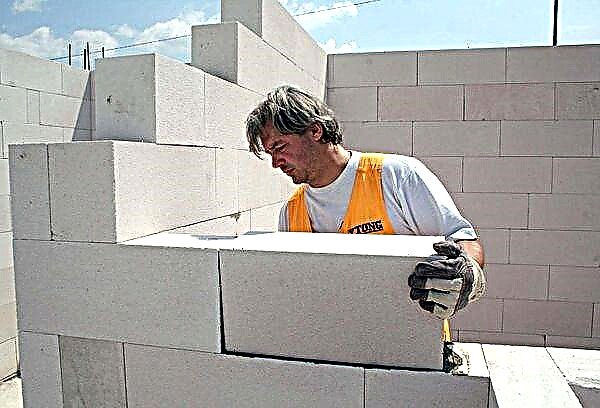

The technology in accordance with which the laying of aerated concrete blocks on the adhesive mixture is very different from the process of building walls on a cement-sand mortar.

Stages:

- Preparation of gas blocks.

- Preparation of the solution.

- Application of adhesive mass on the surface of aerated concrete block.

- Laying and leveling the gas block.

- Removing excess adhesive mass.

The subtleties of the masonry technology are that the unit must be clean, it is strictly forbidden to apply glue to the material covered with ice. In addition, it is not required to moisten the gas block during the laying process, except when construction is carried out in the summer in the heat.

Advice! The proportions of the dilution of glue with water and the method of preparation of the solution are indicated by the manufacturer on the packaging. Keep in mind that there should not be too much water.

A homogeneous consistency of the adhesive mass can be obtained by stirring it with special nozzles that are mounted on electric tools (for example, a drill). After the first stirring, let the solution brew for 10-15 minutes. This will ensure complete dissolution of the additives that make up the glue. Immediately before use, glue must be stirred again.

Depending on the brand, the adhesive mass can be used for 2-4 hours. It does not make sense to dilute the masonry mixture that has begun to harden with water - its useful qualities are already lost.

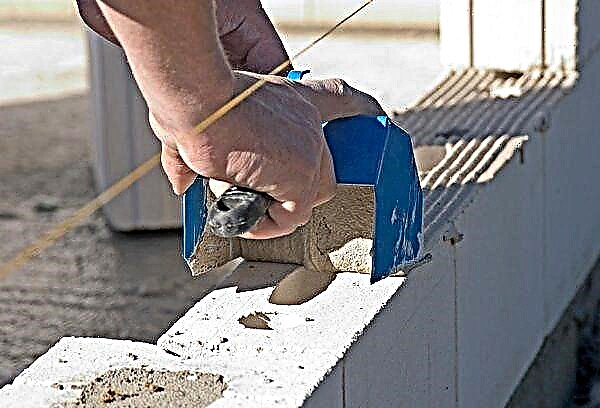

Glue on the blocks is applied by means of a notched trowel or a special carriage designed specifically for such a masonry mixture.

The positive effect of the use of special tools is to significantly reduce the consumption of adhesive mass, improve adhesion and reduce the time to complete the work.

The thickness of the glue layer will depend on the size of the teeth. In order to avoid wall obstruction, it is necessary to place blocks on a stretched cord. Masonry control is carried out by the building level. Alignment of blocks is carried out with a rubber hammer, which allows to prevent damage to aerated concrete blocks. Excess glue is cut off after hardening with a trowel.

Glue consumption calculator

For one square meter of aerated concrete, the consumption of masonry mix is normally about 1.5-1.6 kg of dry glue, provided that the layer thickness is 1 mm. For one cubic meter, the consumption will be from 15 to 30 kg of dry mix, that is, on average 1 bag (25 kg). In practice, consumption increases to 1.5 bags per 1 cubic meter.

Factors on which how much glue will go per 1 m 3:

- quality and variety of masonry mixture,

- qualification and experience of the master,

- state of gas blocks, surface, defects and damage,

- ambient temperature and weather,

- the number of reinforcing layers.

Advice! Special construction tools available reduce consumption.

Follow the recommendations below and the instructions on the packaging, and feel free to proceed with the implementation of your architectural ideas!

Is it possible to put gas blocks on a cement mortar?

The use of cement mortar for laying aerated concrete is not recommended for several reasons:

- joint thickness 10-12 mm,

- the composition of the solution is not constant,

- a long preparatory period, from screening sand to kneading, which increases the working time,

- significant dustiness of work,

- the appearance of cold bridges at the junction of the blocks, and this is additional heat loss,

- difficulty in laying walls in winter. Due to frost, the mixture must either be kneaded in small portions or constantly heated.

Tool for applying glue to aerated concrete blocks

A new tool has appeared on the market that simplifies the application of adhesive solution (controlled thickness of the adhesive layer when laying aerated concrete) - a special container, trowel-bucket or carriage for aerated concrete. These are different names for the same device.

Carriage for aerated concrete

Carriage for aerated concrete  Application of glue with a carriage (trowel)

Application of glue with a carriage (trowel)

Thanks to these devices, the laying of aerated concrete blocks is faster and with minimal glue consumption, and the cost of work is reduced.

Advantages of glue for gas blocks:

- plasticity of the material and fine-grained filler (not more than 0.63 mm) allows to achieve a weld thickness of 2-3 mm. Those. consumption is reduced at least 4 times, and the thickness of the seam is reduced, which reduces the total area of the joints and, as a result, eliminates the growth of heat loss through the seams,

- a bag of dry adhesive mixture (25 kg) requires only 5.5 liters of water. This means that the moisture content of aerated concrete does not increase significantly,

- the composition of the adhesive solution is always the same, which allows to ensure the same adhesive performance,

- the mixture contains additives (antifreeze), which give it frost resistance and moisture resistance,

- glue can be used as putty. This eliminates the appearance of residues,

- the amount of glue from the finished mixture is easier to knead as much as you need to work,

- the presence of special winter adhesives for aerated concrete allows you to perform work in the cold season,

- glue can harden without shrinkage.

The only conditional minus of glue is setting time. The glue hardens for about 10 minutes. At the first stage, this can create some difficulties for beginners.

How to use glue for aerated concrete

- keep warm (not lower than + 5 ° С),

- knead with warm water (up to + 60 ° С),

- aerated concrete should not be covered with snow (in this case, its humidity increases, which means that the properties of the adhesive decrease),

- glue spatulas or carriages should be kept in warm water,

- use containers only for glue, otherwise larger impurities may appear. This will not significantly affect the properties of the adhesive, but it will be necessary on the thickness of the layer (as a result, the glue is overused).

These recommendations are not indicated on the packaging of the adhesive, but are obtained from practical experience.

As the main argument, adherents of the classic cement mortar recipe call the high cost of glue. Correctly and objectively, the adhesive mixture is more expensive. But if we take into account the consumption of glue for aerated concrete per m3, it turns out that a bag of glue mixture is enough for laying 1 m3 of aerated concrete, and only a third of “home” mortar, then the cost overrun is obvious.

The composition of the adhesive for aerated concrete

The main components of adhesive mixtures for aerated concrete are:

- cement of the highest category,

- mineral components

- and polymer additives.

The cement, which is part of the material, requires the observance of precautionary measures, namely the use of gloves and a respirator when working with a protection solution for hands and respiratory organs.

Most often, two types of glue are used:

- White glue is intended for work indoors and during outdoor construction in the summer,

- Glue of gray color is allowed to work in any season of the year, including the winter period.

White glue It includes high-quality Portland cement, which provides an external resemblance to aerated concrete, so that you can achieve an economic effect in interior decoration. The wall as a result of the use of this glue turns out to be of a uniform color, there is no need to deal with sealing joints between the blocks.

Gray glue It is considered a universal material, it includes additional components, so it can be used in the winter, also at subzero temperatures (at least -10 degrees).

Adhesive foam for aerated concrete and its application

Recently, the use of polyurethane foam for joining aerated concrete blocks has gained great popularity. Glue-foam has many undeniable advantages, so its use has become almost universal. Polyurethane adhesive for aerated concrete provides a strong connection with minimal material consumption. A significant drawback of this adhesive material is its high sensitivity to ultraviolet light, which can destroy its structure during the year, therefore, when using adhesive foam, this factor should be taken into account.

The use of such an adhesive material significantly reduces the cost of the construction process and allows it to be significantly accelerated by eliminating any “wet” processes during the construction of the building. Polyurethane can be attributed to frost-resistant adhesives for aerated concrete, it also significantly increases the thermal insulation properties of the building.

Glue additives and their purpose

It is additives that are those components that provide the material with its properties.So antifreeze additives provide the ability to use glue in the winter.

The basis for the adhesive are the following components:

- High quality Portland cement, used as the main binder component,

- Minimum sand fraction,

- Polymer additivesproviding mixtures with extra viscosity and strength. It is polymers that allow the mixture to expand, as a result of which all existing voids and irregularities are filled,

- Modifiers - these are special additives capable of providing part of the moisture inside the material, which allows the adhesive joint to not crack, tolerates atmospheric effects and temperature changes.

Additions to glue for aerated concrete during frost increase its thermal conductivity and allow the use of glue in the winter.

Glue consumption rate

Adhesive for aerated concrete winter or summer is available in packages weighing 25 kg. For mixing, take about 5-5.5 liters of water. Thorough mixing is carried out using a construction mixer, after which the glue must be infused for 10 minutes, after which it should be mixed again. If excess moisture is added to the material, it will lose its transparency properties.

The consumption of adhesive for aerated concrete per 1 m3 will be approximately 18-26 kg, that is, one bag. To avoid overspending, it is necessary to strictly follow the technology of manufacturing the mixture. The mixture is gradually added to water (and not vice versa), and thoroughly mixed with it. The consumption rate of glue for aerated concrete is considered, taking into account the layer of applied material within 2-3 mm.

The average cost of material in the market

The price of glue for aerated concrete is acceptable. This material is produced by many well-known manufacturers of building mixtures. A standard bag of glue weighing 25 kg will cost about 200 rubles, including winter glue from AEROC and Volma-Block. Among other manufacturers of glue, one can distinguish the following companies: Polygran, StroyKomplekt and others. The affordable price for glue for aerated concrete blocks allows you to significantly reduce the cost of a building project, which increases the profitability of the building.

How to choose glue for gas blocks?

The solution to the problem is complicated by a significant variety of adhesive compositions on the market.

The easiest way to decide is to conduct small tests.

Test 1. Take several types of glue and glue each two aerated concrete blocks. After a day, break the connection and look at the place of the fault. If the fault goes along the seam, such glue is not suitable for use. If the blocks themselves are partially deformed and partially deformed, then the use of such glue is in doubt. If the seam remains intact, and the gas block is damaged - this is the best glue for aerated concrete. This glue should be preferred.

Test 2. Prepare for use 1 kg of each of the tested types of glue. Clog the same containers with them. After hardening (day), weigh. Preference should be given to glue from the container whose weight is less. Light weight indicates that most of the moisture is gone, which means that the mixture is less heat conductive.

Anticipating a healthy share of the irony of readers, we note that testing several adhesives is certainly troublesome and costly. But it will be useful to those who have a couple of types of glue and do not know which one to choose.

We indicate the brands of glue for aerated concrete blocks that have been tested by professionals and deserve their approval.

Ceresit CT 21

Glue for aerated concrete Ytong-house-keeper

Glue for aerated concrete Founders Selfform MC112

Bonolit aerated concrete adhesive

Adhesive for aerated concrete Baumit PorenbetonKleber

AEROC aerated concrete adhesive winter

Where to use?

Glue for aerated concrete is a special dry building mixture, which is diluted with water in the proportions specified by the manufacturer. It is used instead of the usual cement mortars for both external and internal works.

Use it for:

- masonry blocks of gas and foam concrete, expanded clay and cinder blocks, bricks,

- alignment of wall surfaces, their putty,

- laying ceramic tiles.

Seasonal Varieties

Now for the construction of buildings used two varieties of mixtures. Glue for aerated concrete blocks happens:

- White. It is considered summer, it is used in the warm season. He owes a light shade (the same as that of autoclaved aerated concrete) to white Portland cement, which makes it possible to save on interior decoration.

- Gray. Although this species is called winter, it is universal, suitable for work in any season. Due to the presence of antifreeze additives in the composition, it is recommended for use in cold weather, however, it also has a certain temperature limit.

The composition and characteristics of the mixture

The composition of the adhesive for aerated concrete includes:

- high quality cement

- fractional (sifted in a special way) sand,

- polymer additives that serve to improve the adhesive qualities of mixtures, their thermal conductivity,

- modifiers due to which the joints do not crack when the temperature rises.

Among the advantages of compositions for working with aerated concrete include its characteristics:

- the ability to make thin seams (only two to three millimeters thick), which allows to reduce heat loss through joints, reduce construction costs,

- frost and moisture resistance

- the ability to work in cold weather (with winter glue),

- hardening without shrinkage.

Necessary tools

To prepare the solution you will need:

To prepare the solution you will need:

- a container in which it will be necessary to mix the dry bulk mixture with water,

- a drill with a special nozzle (to get the correct consistency of the density of sour cream use a construction mixer),

- measuring device to maintain the correct proportions.

To apply glue and implement masonry, use a steel or gear spatula, a trowel-bucket (carriage) for aerated concrete.

Cooking method

Dry mixes are realized in 25 kg bags. For the preparation of the adhesive composition, the calculation is as follows: for one factory packaging, five to five and a half liters of pure water are required (that is, 200-220 milligrams are taken per 1 kg). The fluid should be warm (15-18 to 60 ° C).

After kneading, a mass without lumps should be obtained. She needs to be allowed to "stand" for five to ten minutes, and then stir again. The glue is suitable for use in just a couple of hours, so it is prepared in batches.

Application Method

On clean blocks (without dust, dirt, oil stains) glue for aerated concrete is applied with a minimum layer. The thickness of the joints during masonry should not exceed 2-4 mm. The excess is removed immediately or cut off with a trowel after solidification. You can adjust the position of the blocks for about ten minutes (with a rubber mallet). Level the surface with a light tap

On clean blocks (without dust, dirt, oil stains) glue for aerated concrete is applied with a minimum layer. The thickness of the joints during masonry should not exceed 2-4 mm. The excess is removed immediately or cut off with a trowel after solidification. You can adjust the position of the blocks for about ten minutes (with a rubber mallet). Level the surface with a light tap

Note. It is necessary to protect yourself from getting the finished solution in the eyes and on the skin, so the use of protective clothing, gloves is recommended. A respirator or gauze bandage will not interfere.

Winter work

For masonry in the cold, a gray winter compound is used. However, as we already mentioned, there is also a certain threshold for it (the temperature “overboard” cannot be lower than -10 ° C, manufacturers usually recommend a value of 5 ° C). For the solution itself, the temperature is maintained above zero - only if this condition is met, is a good adhesion of materials.

Note. Do not stick together frozen blocks sprinkled with snow - this is not allowed by technology.

Material consumption

According to experts, the consumption of adhesive for aerated concrete per m3 of masonry depends on the size of the "bricks", the surface condition of the blocks, that is, the accuracy of their geometry, the presence of defects (cracks, chips, etc.), as well as the skill of builders. As practice shows, on average, one and a half bags of dry basis are used per m3.

To determine more precisely, they offer certain formulas that are convenient for calculating the consumption of dry glue in kilograms per m3 of masonry, based on the length, height of the gas blocks, and the thickness of the joints.

Well-known manufacturers

As an example, pros usually recommend several already established brands of adhesives for aerated concrete. Among them:

- AEROS. For external, internal works, in winter / summer options,

- Ceresit CT21. For internal, external types of masonry, putty of internal surfaces,

- Moment. It has high adhesion to the base,

- Kreisel 125. In addition to gas and foam concrete, it is suitable for laying polystyrene concrete blocks, foam concrete,

- Bonolit (Bonolit). A relatively new brand. It is interesting in the presence of antifreeze modifying additives,

- Volma - Block Frost-resistant. Installation is possible at temperatures up to -15 ° C.

Experts recommend not saving on the quality of glues, choosing trusted manufacturers, those brands about which there are consumer feedback. If dry products are purchased “for future use”, they must be stored in unopened packaging. The room used for storage should be dry, heated. Subject to these conditions, the shelf life is one year from the date of production of the material.

Determination of adhesive for aerated concrete

This composition is a dry building mixture, which is prepared on a water basis. The packaging of goods from the manufacturer always indicate the proportions of water and glue. This tool has become an excellent alternative to conventional cement mortar when performing work inside and out during the construction process.

Since its inception, the adhesive has been widely used. It is used as a putty for leveling walls, laying ceramic tiles. However, most often with the help of such glue build walls from many building materials:

aerated concrete and expanded clay blocks,

aerated concrete and expanded clay blocks,- brick,

- cinder block

- foam block.

Now manufacturers produce two types of glue for aerated concrete blocks. This mixture is used depending on the season.

For example, white glue for aerated concrete is suitable for the warm season. It got its name because of the main component - Portland cement. This substance gives it a light shade, which allows it to be applied when laying light blocks, as well as for puttying inside. It makes it possible to save on finishing materials.

Gray glue belongs to winter compounds, since frost-resistant additives are present in its composition. The finished solution is considered universal, therefore it is suitable for work at any time of the year, but with some temperature restrictions.

Main advantages

Lightness and good performance of aerated concrete made it popular and in demand in construction. For its installation use special glue. Manufacturers produce such a composition of good quality, since it includes polymer additives, modifiers and sand sifted in a special way.

Polymer additives help to improve the thermal conductivity of the composition and its adhesive properties. Due to the modifiers, protection is provided against cracking at elevated temperatures in the street. It is worth noting and other advantages when laying aerated concrete on glue:

ductility and fine-grained filler allows masonry with a joint thickness of 2-3 mm, which makes it possible to reduce consumption by at least 4 times and makes joints thinner, eliminating heat loss of the structure,

ductility and fine-grained filler allows masonry with a joint thickness of 2-3 mm, which makes it possible to reduce consumption by at least 4 times and makes joints thinner, eliminating heat loss of the structure,- on a bag weighing 25 kg, it is necessary to add only 5-6 liters of water, why the humidity of aerated concrete does not increase significantly,

- the same and uniform composition of the mixture provides similar gluing performance,

- anti-frost additives guarantee moisture resistance and frost resistance of the material,

- due to the fact that the composition can be used as putty, its residues after completion of work are excluded,

- it is convenient to knead a certain amount of glue required for masonry,

- the type of adhesive for the cold season makes it possible to produce masonry at a low temperature,

- the ability to harden without shrinkage.

In addition to the undeniable advantages of such a tool, it has a single minus. The setting time is about 10 minutes, and if a beginner does the work, it will be difficult for him to use the ready-made solution at the first stage.

Factors affecting the expense of funds

The amount of composition spent during masonry work per 1 m 3 will depend on several components. This is, first of all, the composition of the adhesive mixture. For example, if there are more modifying additives and sand in it, then the consumption will be more. The high content of binder components will prevent overspending and save on material.

Laying literacy matters, because often young masters spend more than necessary. However, this indicator does not contribute to quality work. If a reinforced layer is present on the working surface, the composition consumption will increase.

Sometimes when a treasure is found, aerated concrete blocks with marriage. In this case, the consumption also becomes larger due to a material defect, since in order to obtain an effective result, a larger amount of the working mixture has to be spent.

The overall flow rate will also be affected by the geometry of the surface of the blocks outside and weather conditions. In practice, an average of 1 m 3 leaves no more than 1.5 bags of dry adhesive mixture.

Criterias of choice

On the modern market a wide variety of compositions are presented. This factor puts consumers in a quandary. Most often they do not know which glue for aerated concrete is better to choose. Experts advise you to conduct a simple test before buying.

In the first case, you need to buy several types and glue each of them 2 blocks of aerated concrete. After about 24 hours, break the connection and look at its break. He will pass it at the seam, then such glue is not suitable for work. Partial kink and deformation of the blocks themselves usually raises doubts about the quality of the goods. The composition is considered the best, where the seam remains integral, and only the gas block after the impact becomes unusable. Such a composition should be preferred.

In the first case, you need to buy several types and glue each of them 2 blocks of aerated concrete. After about 24 hours, break the connection and look at its break. He will pass it at the seam, then such glue is not suitable for work. Partial kink and deformation of the blocks themselves usually raises doubts about the quality of the goods. The composition is considered the best, where the seam remains integral, and only the gas block after the impact becomes unusable. Such a composition should be preferred.

The second test option is to prepare a finished mixture of 1 kg of each type. After that, they fill the same containers. During the day, the mixture hardens, then it must be weighed. The best solution is considered to be a solution with a minimum weight. This indicator suggests that the composition contains little moisture and the adhesive has the property of low thermal conductivity.

Such testing will be troublesome and expensive. However, to perform the masonry work, you will have to spend much more money, so it is preferable to do tests at the initial stage of construction. Professionals recommend using special tools during installation to help reduce the consumption of the mixture.

Rating of the best brands

Despite the huge selection of adhesive mixtures on the shelves of construction stores, it is worth listening to the advice of specialists. Thanks to their experience, they know more and can determine which glue for aerated concrete blocks is better to choose.

According to professionals, it is better to give preference to several companies involved in the production of glue. Many types of products managed to earn trust with their quality and characteristics. Good reputation The following brands are used:

Benolit - appeared relatively recently and in its composition there are components with antifreeze properties.

Benolit - appeared relatively recently and in its composition there are components with antifreeze properties.- Moment - has high adhesive qualities with respect to building material.

- Volma - is distinguished by good resistance to low temperatures, which allows you to work with the mixture at -10 C.

- Kreisel 125 is a universal composition suitable for laying not only aerated concrete blocks, but also other materials.

- Kreps - suitable for external and internal styling and retains all its qualities for 4 hours.

- Ytong is a high-strength polyurethane adhesive that holds water well, has excellent adhesive properties, and is available in two popular types for winter and summer use.

- Real - allows you to perform construction work at +5 and up to +30 C, suitable for work outside and inside.

- Ceresit CT 21 - an excellent option for indoor and outdoor use, as well as for finishing in the form of putty.

- AEROC - under this brand, the company produces white and gray masonry mix for indoor and outdoor work.

It is recommended to choose fine-grained compositions for laying aerated concrete blocks. This will help to avoid the appearance of cold bridges due to the homogeneity of the solution. The composition of any manufacturer is recommended to be stored at low humidity in a heated room. This will preserve all the properties and suitability of the material.

Glue consumption for aerated concrete

A bag of dry mix of 25 kg is dissolved in 5-6 liters of water, resulting in a bag of 18 liters of finished glue.

The consumption of glue (dry masonry mixture) for thin-masonry laying (seam 1-3 mm) per meter cubic meter. is 16-17 kg.

The shelf life of the finished adhesive mixture is 2-3 hours. The time for adjusting the blocks after laying is 10-15 minutes.

The consumption of adhesive for aerated concrete directly depends on the size (the specified calculation data is oriented to blocks 600 and 300 mm high) and the quality of the surfaces of the aerated concrete (poor geometry, chips and defects increase the consumption), as well as on the professionalism of the bricklayer. Therefore, the calculated values may differ from the real ones. It’s better to carry out a stock calculation.

Technology for the preparation of adhesive for aerated concrete

Each manufacturer applies the instructions for use on the packaging. But as a general rule, we indicate:

- the required volume of water is measured,

- the mixture is poured into the water in small batches,

- mixed with a mixer until a homogeneous mass for 5 minutes,

- the mass should "rest" for 5-10 minutes during which time the polymer additives will open,

- mix the solution again

- during operation, mix the solution periodically.

The optimal consistency of the glue is considered, in which the teeth that appeared on the surface after applying the glue with a notched trowel (comb) do not blur.

External factors:

- environmental humidity. Walls of aerated concrete must be laid in the dry season. Then the glue will harden at the optimum speed. During rain, snow and strong wind - it is impossible. Actually, as it is undesirable to work with dirty, wet and icy blocks,

- air temperature. The hotter, the faster the hardening process will go, which can lead to the appearance of shrinkage cracks. In the cold season, glue will harden more slowly.

aerated concrete and expanded clay blocks,

aerated concrete and expanded clay blocks, ductility and fine-grained filler allows masonry with a joint thickness of 2-3 mm, which makes it possible to reduce consumption by at least 4 times and makes joints thinner, eliminating heat loss of the structure,

ductility and fine-grained filler allows masonry with a joint thickness of 2-3 mm, which makes it possible to reduce consumption by at least 4 times and makes joints thinner, eliminating heat loss of the structure, Benolit - appeared relatively recently and in its composition there are components with antifreeze properties.

Benolit - appeared relatively recently and in its composition there are components with antifreeze properties.