A special pigment provides a glow of fluorescent paint, the fluorophore converts and transmits ultraviolet rays absorbed by it into the visible part of the spectrum.

Fluorophores are usually represented by substances such as rhodamines, as well as derivatives of aminonaphthalimide. Since in pure form these components are too expensive, they paint the smallest particles of the polymer dispersion, obtaining the special, fluorescent pigment that is added to the base of the material in the manufacture of paint.

Such a coating is not able to absorb and accumulate light, unlike luminescent paints that glow in the dark without any external influence. They contain another active substance - a phosphor, and in another way these colors are called neon. Fluorescents only reflect the rays of the sun or the light of ultraviolet lamps.

Out of home

- road markings, signs and signs, parking lots and runways,

- signs of cafes and shops,

- billboards,

- facades of buildings with lighting and appropriate decoration, stained-glass windows,

- graffiti,

- airbrushing on cars, inscriptions on special vehicles,

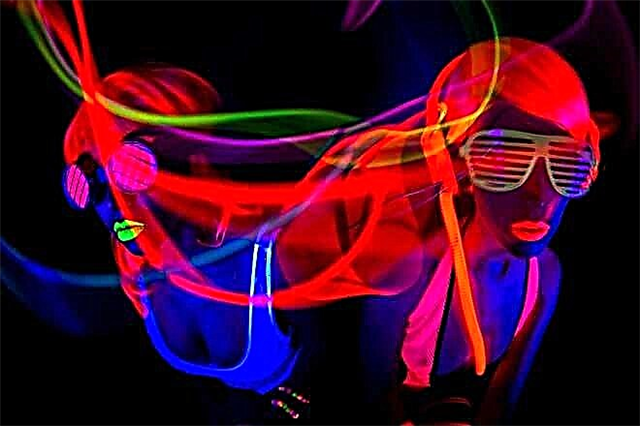

- interior design of night clubs and restaurants.

At home

- wall and multi-level ceilings in the bedrooms,

- creating a fabulous atmosphere in children's rooms,

- restoration and stylization of outdated furniture.

If the artist is engaged in applying a luminous drawing, the apartment will literally sparkle with new colors, completely transforming in the evening and night. However, adding some simple elements to the interior with the help of luminous compositions is possible and independently.

Body painting

- Temporary tatoos,

- body art

- face painting.

This type of painting is used as entertainment at children's parties and attractions, as well as at stylized parties or masquerades. To work on the body, a special composition of glycerin, lanolin and a fluorescent pigment mixed with water is used.

Important: before applying the paint to the body, it is necessary to conduct an allergy test by making a small smear on the inner elbow and wait about half an hour. If there is no reaction in the form of itching or redness, then you can begin to create the main picture.

It is easy to wash off such a composition with scrubbing products for body care or warm soapy water.

Acrylic composition for interior use

Fluorescent acrylic paint for interior decoration has the following advantages:

- you can mix materials of several colors to create the desired shade,

- the composition has no unpleasant odor and is absolutely non-toxic,

- the coating is suitable for wooden and plastered surfaces; it lays well on drywall.

- low moisture resistance

- not suitable for painting surfaces made of metal and plastic.

For the walls of the bedroom or living room, these compounds are ideal, but the repair in the bathroom is best done using other means.

Front acrylic paints

The use of acrylic fluorescent paints for facade work is a wonderful way to give the building a festive and solemn appearance, especially since these materials have excellent quality characteristics:

- increased resistance to temperature extremes,

- moisture resistance

- abrasion resistance

- high vapor permeability, lack of smell,

- good adhesion with almost any kind of surface, including plastic, galvanized metal, concrete and others,

- the coating is not afraid of detergent treatment.

If the material is purchased to create a light picture on the wall, then before starting work it is usually diluted with water.

Universal compounds on an urethane-alkyd base

Spray paints in spray cans are used on different surfaces, and even on glass. The coating is very resistant to the negative effects of external factors. It is with such paints those who are engaged in airbrushing for cars. If someone dreams of a fluorescent bathroom or toilet with luminous patterns, then spray paint is the most suitable option.

Invisible paints

Invisible fluorescent paint is almost invisible in daylight on bright surfaces, and on dark it can be found in the form of whitish streaks. Such material is used both for the execution of unusual design decisions, and for night illumination of road signs.

Invisible paint, paradoxically, has a rich color palette. Walls or ceilings, quite ordinary during the day, magically transform in the evening or at night: in the ultraviolet of lamps, intricate ornaments or romantic landscapes appear on their surfaces.

“Visible” paints practically do not differ during the day from the rest of the paint coatings, since their luminescence also becomes noticeable only under ultraviolet rays against the background of darkness or twilight.

Common disadvantages

- Unfortunately, coatings cannot forever fluoresce, since they have a rather weak resistance to direct sunlight. Avoid quick burnout by using protective equipment, for example, transparent varnishes. When acquiring such a composition, it is important to make sure that it does not have matting properties, in which the glow effect will be significantly reduced.

- The texture of the fluorescent dispersion does not allow achieving a glossy surface finish. When such a need arises, you can resort to the method described in the previous paragraph.

- Material does not belong to heat-resistant compositions. It is destroyed at a temperature of + 100-150 ° C.

How to do it yourself

To create a luminous paint, you need to mix only two components:

- clear acrylic lacquer,

- fluorescent pigment in powder form, which can be bought at a specialty store or online.

It is desirable to immediately select the second ingredient by color - a colorless polymer pigment to a large extent loses its fluorescent properties when tinted.

For four parts of the varnish, one part of the powder is taken, the composition is thoroughly mixed, and after this you can start the staining process.

Surface preparation for painting

To create a high-quality coating, several conditions must be met:

There should not be chalk or lime on the surface.

The base must be cleaned or washed of contaminants and dried.

Before applying the "visible" paint, it is recommended to cover the surface with a white acrylic primer.

Dyeing

In application, fluorescent acrylic paints practically do not differ from similar formulations without a “magic” pigment. If this is not an aerosol, then the following tools will be required:

- brushes

- paint roller

- tray,

- You can also use a spray gun.

Fluorescent dyes are usually applied in two layers. The more layers, the brighter the glow effect. The time interval between stains should be at least three hours. Full drying occurs in a day.

Store the coloring agent in a tightly closed container, so the best option for long-term storage is paint in cans.

The principle of operation of the material

Fluorescent paints are luminous. This is a decorative paint material that reacts in a special way to light. Under the influence of the light flux, the painting made with such a paint will look much brighter, although the products, coating composition, will remain beautiful in any light. The intensity of the “juiciness” of color in the dark is approximately 50% greater.

The variety of shades of paintwork is quite large. There are ordinary white paints and colors - blue, pink, black, brown, blue, yellow and many other tones. Means are visible and invisible (colorless). Visible paintwork is easy to distinguish in any light, but when the rays of the sun hit, the pattern gives a stronger glow.

The composition of the paint is represented by such components:

- dyes or pigments (fluorophores),

- polymer resin - acrylic or polyurethane,

- fillers

- binding additives.

Fluorophore gives the material unique properties. The substance is made from rhodamine, aminonaphthalimide, cyanine and some minerals. Most elements are expensive, which leads to a rather high price of fluorescent coatings.

The advantages of the tool cover the disadvantages:

- you can use the product on the street or draw indoors - the composition is universal,

- it is easy to use the material - for work it’s enough to buy a brush or roller, the composition dries very quickly

- in addition to decorative properties, coatings have the ability to protect the base from damage, moisture,

- low material consumption, due to which the paint is quite economical,

- the layer does not fade for a long time, does not fade, remains beautiful,

- the material is environmentally friendly - after drying it does not harm nature and humans.

The use of fluorescent coatings

The material is suitable for various substrates and surfaces - from wood, concrete, stone, metal, plastic. Paint can draw a picture on paper, cardboard, canvas, print. With the help of neon paintwork materials, cars are tuned, car wheels are painted, road signs are marked on the road for the safe movement of cars. Paint is used for walls, flooring in cafes, restaurants, shopping centers, night clubs and even in apartments and houses.

Range of application of the material:

- theater costumes, makeup

- furniture - tables, chairs, cabinets,

- various souvenirs and home decoration,

- clothes, shoes - logos, various elements,

- glass, ceramics, tile, stained glass,

- stone and concrete walkways,

- window frames, gazebo elements,

- bicycles

- body and face painting

- decoration of natural and artificial flowers,

- marking of different signs.

Using fluorescent paintwork, you can easily decorate any item with your own hands, make a craft or a gift, paint the wall, facade of the house. Some paints are widely used for body art - drawing on the body.

Material characteristic

Some fluorescent inks are called ultraviolet inks because of their ability to brighten in the dark. High-quality coatings are safe for health, but it is important to evaluate their exact composition before buying. Cheaper products contain a lot of phosphorus, due to which they glow, but are toxic. You should not buy such materials.

Most fluorescent enamels contain UV filters (modifiers) that protect them from burnout. If such substances are not present, with external use the paint layer will soon fade, because the initial light fastness of the material is low. Another option to increase UV resistance is to apply a transparent varnish with the desired properties on top of the paint layer.

The pigment grains in the composition of the products are always quite large, so the coating will be grainy. To solve the problem, providing the desired density to the layer, you can by applying in 2 layers. Almost all fluorescent coatings do not tolerate heating above + 150 ... + 200 degrees, therefore they cannot be used for thermally unstable surfaces.

The most important averaged technical characteristics of means:

- specific gravity - 1.09 - 1.12 kg / l,

- dry residue - 50 - 55%,

- hazard class - 4 (low hazard),

- consumption - 70 - 90 g / sq.m,

- viscosity according to the device VZ / 245 - 20 - 40 s.

Types of Fluorescent Paint

Construction stores sell many different fluorescent products. A huge selection of sets is presented in Leonardo stores and online centers for artists. The most popular brands - Kudo (Kudo) in aerosols, acrylic spray paints Bosny, Decola, Paint Glow, various materials made in China.

Acrylic materials

Acrylic based paints are the most popular. Thanks to the water in the composition, it is an aqueous dispersion of acrylic. Such means work on paper, cardboard, paint pictures. The material is harmless, non-toxic, has a slight smell. Some acrylic paints are bought specifically for children's crafts and needlework - the compositions are ideal for making drawings on leather, wood. Acrylic dries quickly, easy to use, low consumption.

For body

Typically, body art is preferred by adolescents who often visit clubs and people who lead the life of a “party-goer.” In sets of fluorescent coatings of 8 colors or more, they can be mixed together, creating new shades.

Paints are safe for the skin, are not absorbed, but are quite expensive. Keep on the body until 18 hours, helping to create an original image. Some materials change skin tone and are noticeable during the day.

Fluorescent enamel

Enamels are used for interior work. They have an acrylic or polyurethane base, the color scheme is very diverse. To create new shades, different colors are mixed together. Interior coatings are used to design a beautiful design inside the house, they work on plaster, drywall, wood. Compositions are suitable for metal and plastic, but adhesion will be slightly worse.

Enamels can also be designed for outdoor use (for facades). They added special components that increase weather resistance, resistance to friction, water-repellent qualities. The finished coating does not violate the vapor permeability of the base material. Facade paints are well suited for stone, metal, wood, concrete, brick.

Invisible paint

Invisible paint has one feature. During the day, the coating is almost imperceptible on the surface, and the paint appears only under the influence of ultraviolet light or artificial lighting. It looks almost transparent, it contains special pigments that respond to light.

The difference between fluorescent and luminescent paints

Luminescent paint also belongs to the group of luminous coatings. Its difference lies in the content of special phosphors, which determine the presence of unique properties. Luminescent paints are able to absorb light from various sources from outside during the day, and then they begin to emit it themselves.

How material differs from fluorescent is not difficult to understand. Fluorescent paintwork in the afternoon is beautiful, bright, but practically indistinguishable from simple paint. Luminescent glows at night due to the accumulation of light energy, and is invisible during the day. The duration of the glow is different - from several minutes to several hours.

Luminescent products cost more, and their production requires special permission. Phosphors can work for many years, are physically and chemically stable and resistant to external factors.

Rules and application technique

Depending on the amount of work, you need to purchase tools - a brush, roller or airbrush. For crafts, cotton swabs are often used. Paint should be poured into a convenient container. A small product can be painted by immersion. From a spray can paint is simply sprayed to the surface.

The product must be pre-prepared: wash or clean, dry. Work is carried out at a temperature of at least +10 degrees. The paint is stirred or shaken, perform 2 to 3 thin layers. The balloon is kept at a distance of 30 cm. To create patterns, stencils that were previously cut are used. Each layer should dry for 3 hours or more, depending on the temperature. Final drying lasts up to 24 hours.

Paint tips

The material should be selected by color, resistance to temperature extremes, if it is important. For outdoor work, you need to buy only those materials that contain UV filters. For graffiti, compositions in cylinders or powder are purchased.

It is important to take into account the drying time, the absence of harmful components. The acquisition of high-quality paint is the key to obtaining an excellent result in coloring any products.

What it is?

Fluorescent or phosphor paints are products that, under the influence of the usual or UV glow, make any patterns more voluminous and catchy. This means that the base of this coating consists of a number of pigments (light-accumulating and reflecting light). Sticky to these elements on the walls or fabric helps sticky transparent base. It is often silicone, as well as varnish, glue or water glass.

Things more spectacularly painted in these colors look at night, they are able to decorate any room.

Today you can buy colorless and classic fluorescent products of all kinds of colors. These paints can be created with your own hands at home, thereby significantly saving on the purchase of a finished coating. This unique coloring composition has acquired its qualities from a pigment that can fluoresce as soon as UV rays reach it. The element absorbs ultraviolet light, transforming it, and gives back the visible rays.

The dye is a polymer-type dispersion (in it, the fine polymer particles have a fluoroform shell). It is non-toxic, harmless when used inside rooms, has very impressive properties.

Features

Fluorescent paints also emit light in the daytime. However, in the dark their light becomes 3 times brighter and more saturated. For this reason, this paint is often chosen for night decoration and various types of markings. To make the surfaces coated with such paint look stylish during the day, you can use colored fluorescent products.

They can be white, blue, green, red, brown or blue. Transparent colors will be almost invisible during the day. This dye will not glow on its own. Under the action of ultraviolet rays, its bright glow will increase tens of times.

If you do not know how fluorescent paint differs from a luminescent analogue, it is worth taking a note: the latter has an independent highlighting effect. The duration of this effect can last up to 10-12 hours. For the whole day, painted surfaces absorb light, with the advent of darkness they begin to glow autonomously. This difference allows you to accurately select the desired type of paint.

There is also a reflective dye. It acts as a back reflection of the light flux: as soon as light hits a painted surface, the rays are immediately reflected at 200 - 250 m. This paint is selected to increase road safety.

More often, fluorescent products are used when decorating nightlife venues. In this case, you can highlight anything.

Different types of fluorescent materials are suitable for staining:

- metal products (they can cover car wheels, signs on the road, various items),

- different fabrics (depict drawings on clothes, use for advertising purposes),

- glass and ceramic products (it can be dishware or stained glass painting),

- the human body (can be found in body art) and on the leaves of ordinary plants,

- wood (you can paint fences, decorate arbors, openings of windows and doors),

- stone and concrete (painting walls, garden paths, city alleys, building facades),

- plastic (PVC products, polystyrene and other plastic materials).

In addition to the ability to glow beautifully, fluorescent materials have other characteristic features. Among them there are advantages and disadvantages. Consider the key points.

Low light resistance

Fluorescent inks can burn out in a matter of months under the influence of light (if applied externally). To dyes burn out more slowly, a modifier is added to the composition of the product, which absorbs UV rays. In addition, the coating with the already applied paint can be painted with clear varnish. But the brightness of the glow of the paint will be reduced.

What is fluorescent paint

Ink with a fluorescent effect has the ability to convert ultraviolet radiation with a shift in the spectrum visible to the human eye. Thus, under the influence of UV rays, a surface with such a coating begins to glow in a saturated color. In daylight, this paint gives a brighter and more noticeable color. At night, the paint can only glow under the influence of ultraviolet lamps.

Depending on the type of pigment, fluorescent paint is:

- Visible - in the absence of ultraviolet radiation has its own color.

- Invisible or colorless - does not have its own color, when exposed to ultraviolet light acquires a light blue, yellow, red, pink glow. A pigment that shines only under the influence of a wave of a certain length can be used.

Fluorescent paint, unlike luminescent, is not able to glow autonomously in the dark after the accumulation of charge from a light source.

The use of fluorescent paint

Fluorescent paint in interior design

Paint with a fluorescent effect is widely used in various fields of activity:

- A great solution for outdoor advertising. Under the influence of daylight stands out and draws attention to the background of any other ambient color. At night, using the backlight of ultraviolet lamps, it acquires a bright glow in the dark.

- Used for original design solutions in entertainment centers, clubs, cafes.

- For marking fences and parking lots, runways.

- For artwork, painting, children's art.

- For body painting (face painting, temporary tattoo).

- For inscriptions on special vehicles, rolling stock.

- In modeling and modding.

- For creating paintings with a fluorescent effect on concrete walls, stones, tiles. Creating stained-glass windows and drawings on glass and ceramics.

- For painting metal elements of a car body, disks - use spray paint in spray cans.

- In the textile industry for dyeing fabrics, creating images and photos on T-shirts.

- Ink fluorescent ink for applying invisible marks on cardboard and paper.

- The fluorescence effect is used in the manufacture of banknotes to protect against counterfeiting. If you illuminate such a bill with an ultraviolet lamp, you can see signs that are invisible in ordinary light.

Ultraviolet radiation

The natural and most intense source of ultraviolet waves is sunlight. With the passage of the atmosphere, the earth's surface reaches only ultraviolet radiation UVA with a wavelength of 315-400 nm (only a tenth is absorbed by the atmospheric layer) and a small part (about 10%) of UVB with a length range of 280-315 nm.

The level of UV radiation can be affected by:

- The position of the Sun at a particular time of day and time of year.

- The height of the surface above sea level.

- Cloud cover. Small cloudiness practically does not stop UV rays.

- The thickness of the ozone layer.

- Surface properties reflect ultraviolet radiation.

In the shade, UV radiation is reduced by half or more, depending on the reflective properties of surrounding objects that are under the direct influence of ultraviolet radiation. Snow has the highest reflectance and can reflect up to 90% of UV rays.

Glowing paints with fluorescent effect: composition and features of application

Invisible paint in spray cans

The properties of fluorescence paint gives a special pigment. It consists of solid resin particles that are stained with fluorescent dyes (rhodamines and aminophthalimide derivatives). Pigments can be made for aqueous paints and varnishes and organosoluble systems, while the latter are characterized by increased resistance to solvents and light fastness.

When mixing a paint material intended for certain types of surface with a compatible fluorescent pigment, a fluorescent paint is obtained. Thus, the pigment itself does not affect the scope and application conditions of the film-forming fluorescent coating, it depends on the properties and purpose of the paint material. The most widely used acrylic paints with a fluorescent effect.

The main disadvantage is poor resistance to direct sunlight, which leads to rapid burnout. It is overcome by applying additional transparent coatings with protective functions. Another disadvantage is the difficulty of obtaining a glossy coating due to the relatively large (up to 75 microns) size of the fluorescent pigment in the paint. It should be noted that the heat resistance of the dyes is limited to 150-250 ° C.

The intensity of the glow under artificial lighting depends on the power of the used UV lamps, the number of layers applied and the color of the pigment (yellow, green, red have a higher saturation).

When preparing the surface for painting, in addition to the actions traditional for different types of paints and varnishes, manufacturers recommend covering the surface with a special white primer. This enhances the fluorescent effect and reduces paint consumption.

For body art, a special mixture of fluorescent pigment with water, glycerin and lanolin is used. Before applying to the body, it is necessary to establish whether there is an allergic reaction to the coloring solution. To do this, apply a test smear in the inner region of the elbow joint, if after half an hour there are no redness, then the paint can be applied to any part of the body. Wash off the paint with soap and water and special scrubs to completely cleanse the skin.

If fluorescent paint is used for outdoor workthen the freshly painted surface should be covered with an additional layer of varnish to increase the protective properties and resistance to direct sunlight, which increases the life of the coating. In order to avoid deterioration of a luminescence, it is impossible to use a protective varnish with a dull surface.

DIY fluorescent paint

In the photo, fluorescent pigment

To make a paint with a fluorescent effect on your own, you need:

- Transparent varnish designed for a specific type of surface.

- Fluorescent pigment in powder form.

- Thinner suitable for the selected varnish.

- Glass container.

In a glass container, one part of the pigment is mixed proportionally to the four parts of the varnish. For a more uniform distribution of the pigment and a uniform consistency, a small amount of solvent is added. By changing the proportions, you can change the brightness and saturation of the glow, to get more “poisonous” or “soft” colors. The resulting paint is applied to the surface in 3-4 layers.

Video: fluorescent paint in interior design

The relative ease of manufacture and the growing popularity of fluorescent paints and varnishes leads to a wide selection of products from different manufacturers. Positive feedback on the price-quality parameter is received by Decola art sets of fluorescent paints from the Nevskaya Palitra factory. For decorative and decoration work, it is advantageous to buy fluorescent acrylic enamel in spray cans of the Kudo brand.

Fear of excessively high temperatures

Fluorescent coatings disintegrate at a temperature of +150 - 250 degrees C. They completely lose their ability to shine brightly.

It takes only 15 minutes of bright daylight or artificial light to charge the applied paint for 8 full hours of operation. The process of accumulating light is a completely continuous cycle. Manufacturers guarantee that their luminous paints will work for at least 30 years.

The phosphor can perfectly adapt to normal temperature, it is frost-resistant and is not afraid of heat. For this reason, it is chosen for interior decoration and facade.

Today, fluorescent-type materials can be represented by compositions of three types. Consider the features of each.

Acrylic for interior

Enamels with acrylic base for interior work can be used on wood, paper, drywall and stone. This kind of material is not suitable for use on surfaces made of metal or plastic. The pigment used in this enamel gives the desired color to the entire coating. To get the desired color, usually mix different colors.

Acrylic for exterior use

The fluorescent paint used for facade work has excellent resistance to various atmospheric factors. It will also repel liquid from the surface, will be resistant to abrasion and the effects of cleaning substances. The surface painted with such a composition is easy to wash. Work on facades often requires dilution of compositions with a certain amount of water.

The paint is easy to apply on concrete, zinc, plaster, plastic base, wood and cement. The product does not have an unpleasant or pungent odor.

Universal

The universal composition in the form of an aerosol is produced in small spray cans. This paint is selected to cover the facade and exterior walls. When used, an even coating resistant to various factors is formed. The uniqueness of this is that they can be used to paint any type of base, from glass to metal.

Colorless species are almost indistinguishable during the day and under the influence of light from a simple lamp. This dye emits light only when it gets dark under the influence of a UV lamp. Visible options in daylight are similar to ordinary bright patterns. You can depict an unusual pattern on surfaces of any type, and it will glow as soon as UV rays hit it.

For painting walls, ceilings or facade work, it is more convenient to use spray cans. Their positive qualities are that the paint will perfectly fall on plastic products, wood, glass and concrete products, it will not fade, it will not deteriorate over time.

Volume

An aerosolized paint is best suited for work: if all available material is not consumed immediately, it will be stored in a bottle until the next use. At the right time, you can again realize new original ideas for the design of a luminous image. Volumes of this paint in aerosol packaging for use for different purposes can vary from 100 to 520 ml. You can buy paint in cylinders of 140, 150, 200, 240, 300, 340, 400 ml.

It is difficult to answer exactly what surface area can be painted with one aerosol product of a certain volume: the paint consumption depends on a number of factors. It is important which company produced the paint. Has the meaning:

- coverage factor of the product itself,

- initial surface color

- absorbency of paint,

- the presence of a primer,

- experience with spray paint.

- uniformity of application.

- the tone of the paint (the lighter the shade, the greater the consumption of the dye),

The approximate consumption of such a spray, according to the label of the manufacturers, is 1 square meter. m. approximately 200-300 ml.

Colors

Sometimes, due to their rich colors, fluorescent paints are called acidic, flashy. These are bright dyes that give the impression that they are illuminated from the inside, a look at which irritates the retina. In addition to these tones, saturated pigments are used, given the purpose of a particular room. Bright colors try not to use in the design of the bedroom. In addition, such accents should be small, otherwise they may lose expression.

A win-win design option is to decorate the interior with patterns or use colorless minor accents. If you need more brightness, apply several shades, for example, red, yellow and orange.

To create a harmonious interior, emphasize neutral tones. White or light gray tones are perfect here.

The contrast between the shades is a bold solution to give a catchy design. The more expressive the contrast, the brighter the paint effect. Such a contrast can be achieved by selecting colors located in the color spectrum of shades located opposite each other. If you prefer to use bright colors, the number of colors should not be large, otherwise each shade will compete with the decor.

A huge plus of the fluorescent dye is that even its small application in the interior will make the room design catchy, memorable, add emotionality to the design. A great idea is to arrange a number of objects painted with fluorescent dyes on a snow-white background. This option is in demand in modern residential spaces, for example, it is found in the style of minimalism. Originally transparent colors look on a black, white and grayish background, as well as when combined with pastel shades. Bright furniture, eye-catching decor items and textile products look stylish against a neutral background.

Another popular idea is to install neon lights. Acid tones are in harmony with all natural colors, for example, brown, beige, cream, cream, shades of blue.

Principle of action and scope

On sale, luminous paints are found under different names:

- fluorescent

- luminescent

- phosphor

- phosphorescent.

This is determined by their composition, depending on which the properties and the area of use of the coloring materials are different.

The principle of operation of a coating glowing in the dark is based on the photoluminescence effect, in which light absorbed by a painted surface appears after dark. Bright radiation does not fade and does not fade over time, the stability of the phosphor remains for many years and does not depend on external conditions or temperature changes.

Another component of such paints is varnish. It increases the durability of the coating, protects it from mechanical damage. Often used transparent acrylic, polyurethane, alkyd varnishes. Such a mixture is colorless and is not visible in painted areas during the day. Whereas color paints contain hue pigments.

Luminescent paint has no toxic effect. Lacquer and phosphor in its composition are safe and can be used for interior decoration. At the same time, paint glowing in the dark with phosphorus in rooms is not used due to the high toxicity of the substance.

Luminous coatings use:

- for designer compositions in the interior, which may include an imitation of LED lighting, individual painted elements or neon paintings on the walls,

- to decorate stage costumes and make-up, to create optical illusions with the help of light glare caused by acrylic paint,

- for highlighting reflective elements on highways, road signs, signs, etc.,

- for painting individual parts of flower ikebans, which are convenient for spraying paint in cans,

- for tuning vehicles, to apply airbrushing to a car or paint parts,

- for decor of advertising posters, signs over shops or other institutions.

Main varieties

There are several types of luminous coloring materials that distinguish different light-emitting components in the composition:

- Phosphor (luminescent) paint. Universal coating with fast light-accumulating effect (up to 30 minutes) and stable glow for more than 10 hours. Phosphor-based compounds are used to paint any surface: from walls in an apartment to body art or uniform elements.

- Fluorescent paint. This transparent emulsion is not visible in daylight, but it emits brightly in ultraviolet rays. Acrylic base provides reliability and durability of the coating, which does not fade over time. Painted surfaces have a saturated color: yellow, green, red and purple shades are often used in the design of nightlife venues.

- Phosphor paint. With the advent of modern materials rarely used. The toxic composition makes it unsuitable for indoor use, therefore phosphorescent paint should be used with caution and safety precautions should be observed.

- Reflective paint. It is made with the addition of pigment from colored crystals, which are reflected when light rays hit them. The color range does not change, which distinguishes such enamels from fluorescent ones, which reflect rays in a different color spectrum. Used for the production of special clothing, marking hazardous areas in production, marking on the roads.

Application Tips

For stable adhesion of luminescent paints to the surface, it is important to adhere to the following rules:

- Prepare for painting: remove the remnants of the old coating, remove dust, prevent moisture from entering. For interior decoration, it may be necessary to align the walls or ceiling.

- It is more convenient to use enamels in spray cans, which will color any surface with an even thin layer. To apply thick paint, wide flat brushes are used.

- The phosphor in the solution settles over time, so for a uniform glow before painting, you need to mix the composition.

- Do not overlay paint until it dries completely. Due to the quick-drying varnish base, each layer dries up to 2 hours.

- The brightness of the glow is achieved due to the preliminary primer of the painted surface. On a white or pastel background, the photoluminescence effect will be stronger.

- Despite the harmless composition of luminous enamels, when painting, safety measures must be observed: wear protective clothing, gloves, and protect your eyes.

DIY glowing paint at home

You can make photoluminescent paint yourself. It is made from several components that are easy to purchase at any hardware store. To do this, use:

- varnish for the base, which is selected based on the material intended for painting,

- solution for diluting varnish,

- powder phosphor of the desired shade (price depends on brightness),

- color tint (optional)

- mixing tank.

Stages of preparation of the coloring composition:

- The phosphor powder is mixed with a transparent varnish in a container until a homogeneous mass is obtained. The ratio of components is 2 parts of phosphor and 3 parts of varnish.

- Then the solvent is poured with a volume of not more than 1% of the total amount of paint. For example, to prepare 0.5 l of the mixture, 5 ml of solvent will be needed.

- It is mixed again, to obtain a color shade, the desired color is added to the composition. The amount depends on the desired saturation of the finished paint.

To make a phosphor with your own hands, you will need: pharmacy boric acid, concentrated coniferous powder and a metal stewpan with a thick bottom.

The dry component is added to water (1 g of powder per 50 g of liquid) and mixed in a metal container. Then, 0.5 tbsp is poured into the solution. l boric acid. With the correct ratio of components, its color is yellow.

The resulting thick mixture is heated over low heat until it starts to melt. It is important to constantly interfere with the composition. Bubbles will appear on the surface that need to be pierced. Then remove the stewpan from the heat and cool the mixture.

After cooling, a dry brittle mass is formed. It is crushed to make a bright yellow glowing powder. The phosphor is added to the finished enamel or mixed with varnish and solvent.